Curable composition for sealing optical semiconductor and optical semiconductor device using the same

A curable composition and optical semiconductor technology, applied in semiconductor/solid-state device parts, semiconductor devices, electric solid-state devices, etc., can solve the problem of insufficient adhesion of polyphthalamide and broken die bonding wire Insufficient impact resistance of opening and sealing materials, etc., to achieve good adhesion, not easy to peel off, and improve yield and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

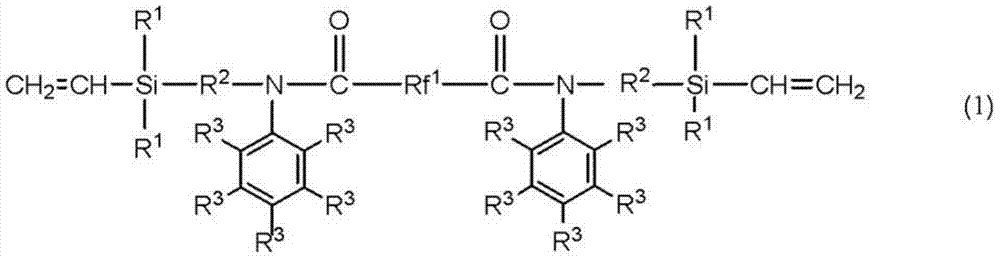

[0271] To 100 parts by mass of a linear fluoropolymer represented by the following formula (23) (viscosity 4,310 mPa·s, vinyl content 0.0909 mol / 100 g), sequentially add platinum-divinyltetramethyldisiloxane complex 0.15 parts by mass of a toluene solution (platinum concentration: 0.5% by mass), 0.20 parts by mass of a 60% toluene solution of 1-ethynyl-1-hydroxycyclohexane, a fluorine-containing organosilane represented by the following formula (24): 17.8 parts by mass of an alkane (0.00486 mol / g of SiH groups) and 3.0 parts by mass of a cyclic organopolysiloxane represented by the following formula (25) were uniformly mixed, and then a defoaming operation was performed to prepare a composition.

[0272] [chemical formula 44]

[0273]

Embodiment 2

[0275] In the above-mentioned Example 1, the straight-chain fluoropolymer represented by the above-mentioned formula (23) was changed to a straight-chain fluoropolymer represented by the following formula (26) (viscosity 4,250 mPa·s, vinyl content 0.0911 A composition was prepared in the same manner as in Example 1 except that mol / 100 g) was 100 parts by mass.

[0276] [chemical formula 45]

[0277]

Embodiment 3

[0279] In the above-mentioned Example 1, the straight-chain fluoropolymer represented by the above-mentioned formula (23) was changed to a straight-chain fluoropolymer represented by the following formula (27) (viscosity 17,800 mPa·s, vinyl content 0.0290 mol / 100g) 100 parts by mass, and the addition amount of the fluorine-containing organohydridosiloxane represented by the above formula (24) was changed to 5.67 parts by mass, and a composition was prepared in the same manner as in Example 1.

[0280] [chemical formula 46]

[0281]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com