Production of potato peel healthcare vinegar through semi-continuous batch fermentation in self-suction fermentation tank

A technology of potato peels and health-care vinegar, which is applied to the preparation of microorganisms and vinegar, methods based on microorganisms, etc., and can solve problems such as high labor intensity, low raw material utilization rate, and long fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

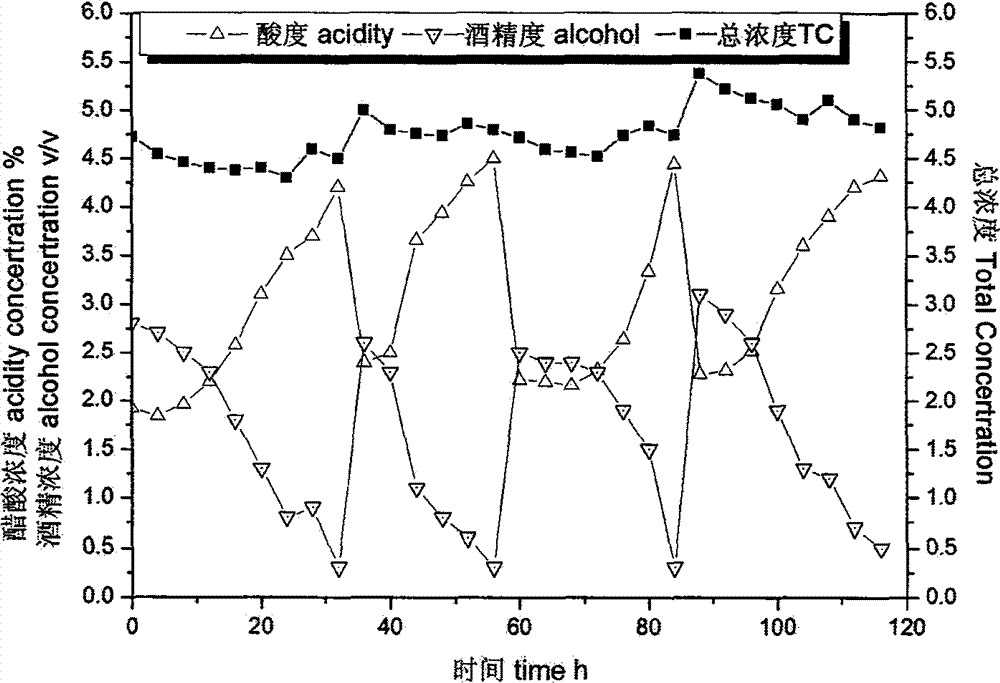

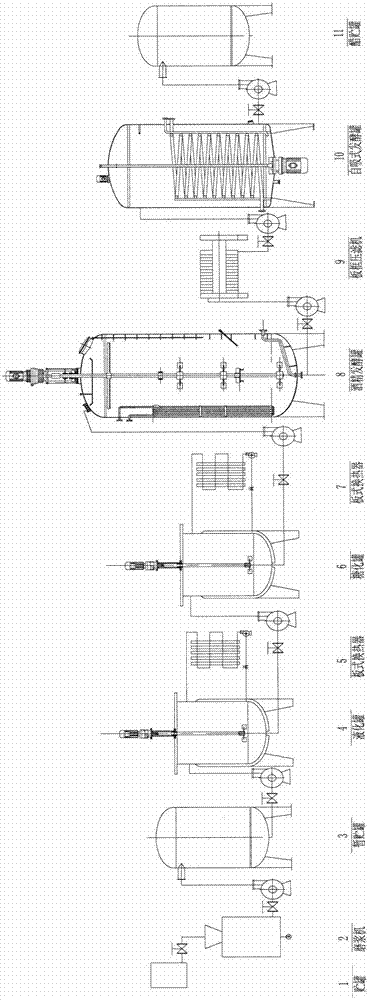

[0022] Weigh 46000g of potato peel residue, add 15U·g-1 liquefying enzyme, keep warm at 96°C for 1.5h, cool down to 60°C, adjust pH to 4.5, add 0.83g·100mL-1 cellulase, hydrolyze for 2h, add 120U·glucoamylase g-1, keep warm at 65°C for 4 hours, cool to 30°C, add 5% Saccharomyces cerevisiae, ferment at 30°C-33°C for 4 days, filter the fermented wine and enter the liquid self-priming acetic acid fermenter, at 30°C, Ventilation volume 1: 0.07~0.1vvm fermentation, 4.6g·100mL-1 potato peel health vinegar was obtained after 16h, and 4 batches of fermentation were carried out in a 15L self-priming fermenter, the average fermentation period was 15h, and the fermentation process parameters See attached figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com