Herbicide composition containing flazasulfuron and use of herbicide composition

A technology for fisasulfuron-methyl and a composition is applied in the field of herbicidal compositions containing fisasulfuron-methyl, which can solve the problems of wasting manpower, incapable of herbicidal effect, improper selection of drugs, and inadequate use technology, and achieves good herbicidal effect, The effect of reducing the cost of use and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

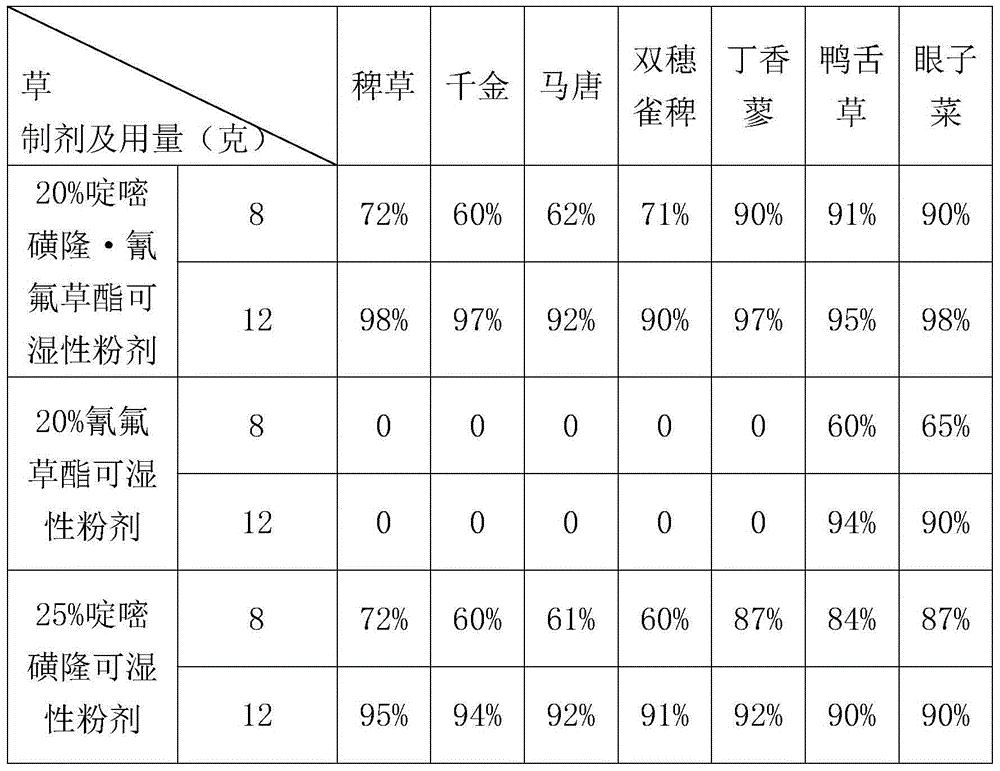

Examples

Embodiment 1

[0027] Process the solid raw drug sulfasulfuron-methyl to 1000 mesh by means of jet crushing, accurately weigh 15% sulfasulfuron-methyl, 5% cyhalofop-methyl in active component B, dispersant alkylnaphthalene formaldehyde Condensate sulfonate 6%, wetting agent alkyl naphthalene sulfonate 4%, adhesive alkyl aryl polyoxyethyl ether 5%, the rest is filler kaolin, fully mixed evenly after replenishing, and finally passed quality inspection After each technical index is qualified, it can be packaged as 20% rimsulfuron-cyhalofop-ethyl wettable powder.

Embodiment 2

[0029] With the method of airflow pulverization, the solid raw drug flusulfuron-methyl is processed to 2000 mesh, and according to weight percentage, take flurimsulfuron-methyl 15%, quinclorac 5%, dispersant alkylnaphthalene formaldehyde condensate sulfonate 4 %, wetting agent alkyl naphthalene sulfonate 4%, binder alkyl aryl polyoxyethyl ether 5%, deionized water is added to 100% for initial mixing, shear stirring, dispersion, and is prepared into a slurry Afterwards, grind for 2 hours through a horizontal sand mill to make the particle size 1 micron, and then it can be configured into a flowable 20% rimsulfuron-quinclorac suspension preparation.

Embodiment 3

[0031] Process the solid raw drugs oxadiazone and sulfadiazone to 3000 mesh by means of jet crushing, and accurately weigh 15% oxadiazone, 5% oxadiazone, dispersant alkylnaphthalene formaldehyde condensate according to weight percentage Sulfonate 6%, wetting agent alkylnaphthalene sulfonate 4%, binder alkyl aryl polyoxyethyl ether 5%, filler kaolin 12% and the rest of water are fully mixed and stirred to form a plastic material. Extrusion granulation, drying, sieving, and finally after passing the quality inspection of various technical indicators, it can be packaged into 20% sulfasulfuron-oxadiazone water-dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com