Preparation method of Nd-based multi-ligand vulcanization accelerator

A rubber vulcanization and multi-ligand technology, which is applied in chemical instruments and methods, organic chemistry, and compounds containing elements of group 3/13 of the periodic table, etc., can solve problems such as poor solubility, and achieve simplified processes and mild conditions , the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

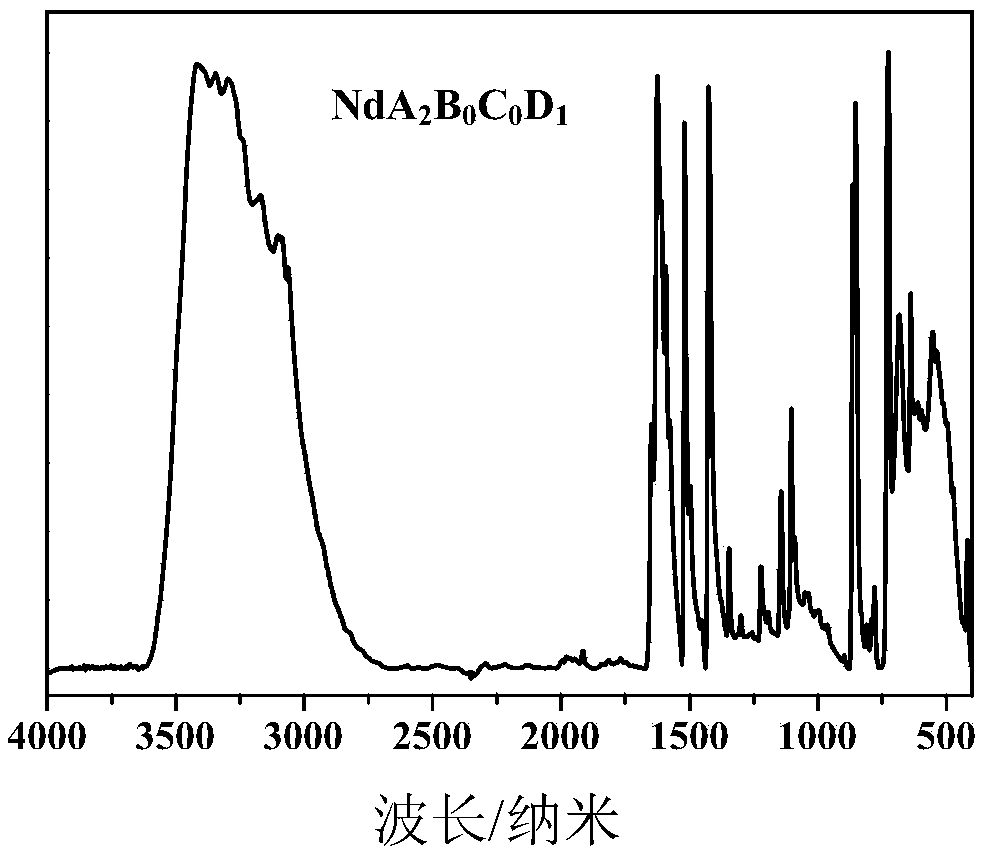

Embodiment 1

[0043] The preparation method of accelerator:

[0044] 0.01molNdCl 3 Dissolve in absolute ethanol at 60°C, dissolve 0.02mol thiosemicarbazide in absolute ethanol at 60°C, and dissolve 0.01mol acrylic acid in absolute ethanol at 60°C. Fully mix the ethanol solution of thiosemicarbazide and the ethanol solution of acrylic acid to obtain a mixed solution. Then the above mixed solution was added dropwise to NdCl 3 in anhydrous ethanol solution, stirred in an oil bath at 80°C for 6h and filtered, and the precipitate was washed with anhydrous ethanol, and placed in CaCl 2 Dried to a constant mass at 20°C in a desiccant desiccator to obtain a light pink powder, the target product NdA 2 B 0 C 0 D. 1 .

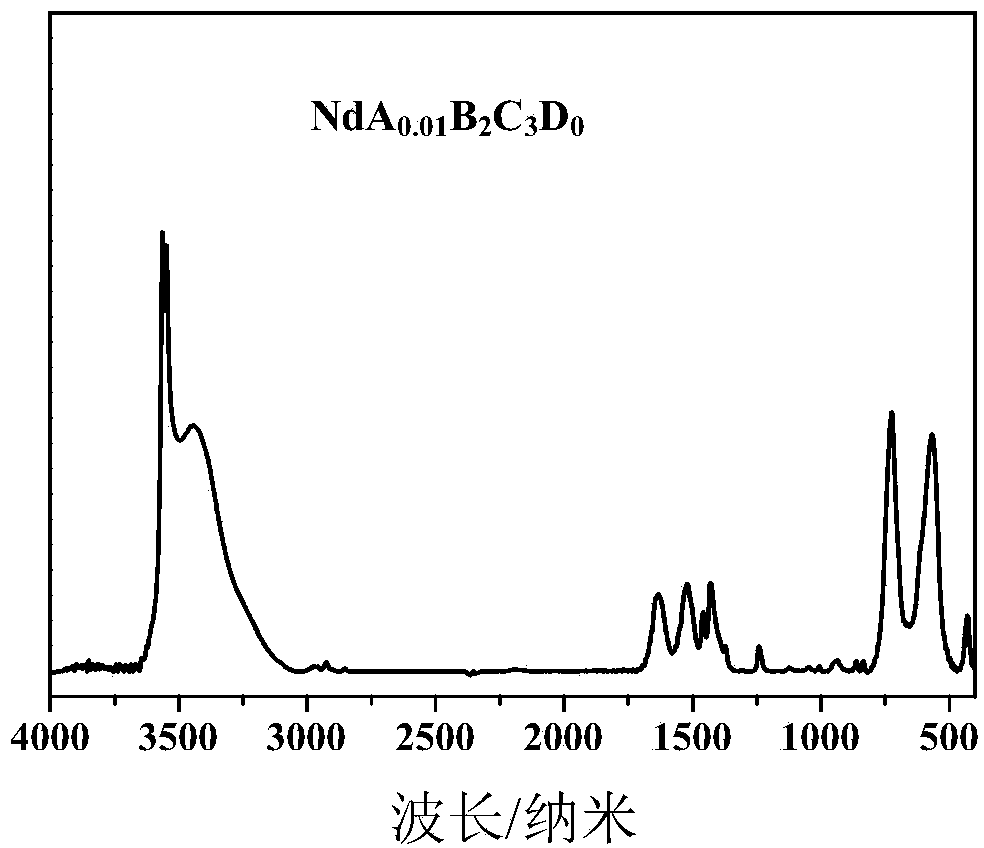

Embodiment 2

[0046] The preparation method of accelerator:

[0047] 0.01molNdCl 3 Dissolve in absolute ethanol at 60°C, dissolve 0.02mol sodium dimethyldithiocarbamate in absolute ethanol solution at 60°C, dissolve 0.0001mol thiosemicarbazide in absolute ethanol solution at 60°C , Dissolve 0.03mol o-phenanthroline in absolute ethanol solution at 60°C. Fully mix the ethanol solution of sodium dimethyl dithiocarbamate, the ethanol solution of thiosemicarbazide and the ethanol solution of o-phenanthroline to obtain a mixed solution. Then the above mixed solution was added dropwise to NdCl 3 in anhydrous ethanol solution, stirred in an oil bath at 80°C for 6h and filtered, and the precipitate was washed with anhydrous ethanol, and placed in CaCl 2 Dry in a desiccant desiccator at 20°C to constant mass to obtain a light blue powder, which is the target product NdA 0.01 B 2 C3 D. 0 .

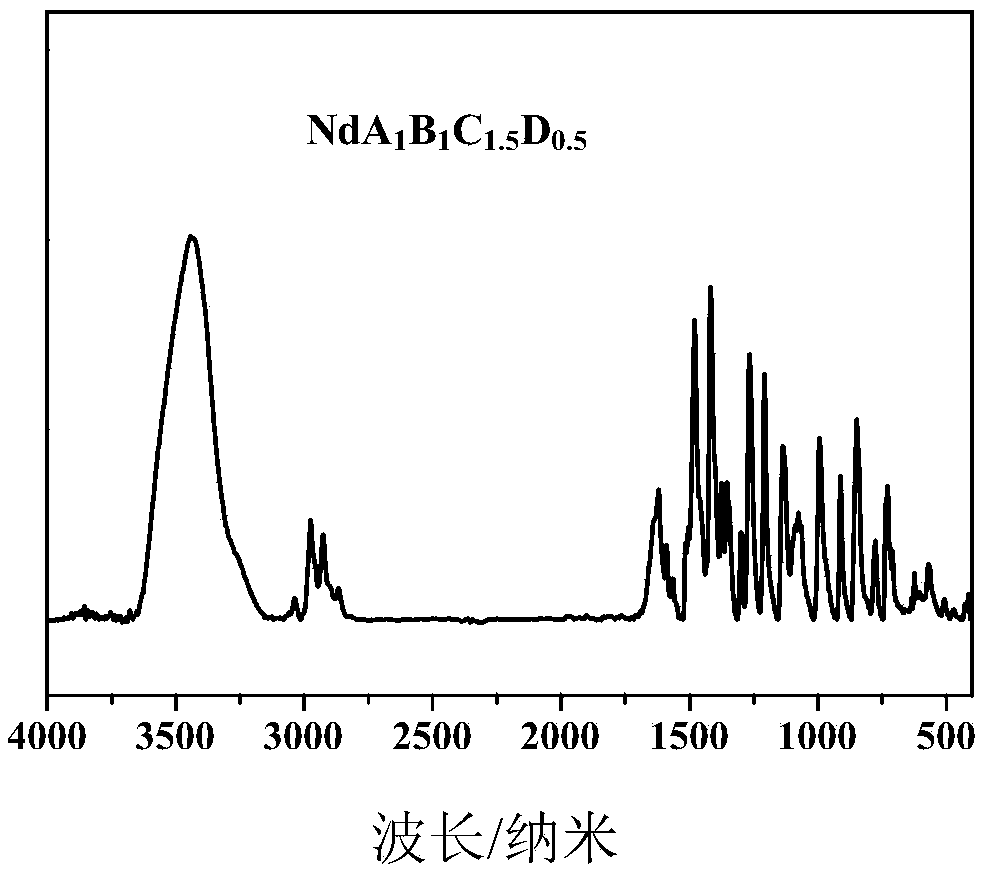

Embodiment 3

[0049] The preparation method of accelerator:

[0050] 0.01molNdCl 3 Dissolve in absolute ethanol at 60°C, dissolve 0.01mol thiosemicarbazide in absolute ethanol at 60°C, dissolve 0.01mol sodium dimethyldithiocarbamate in absolute ethanol at 60°C, Dissolve 0.015mol o-phenanthroline in absolute ethanol solution at 60°C, and dissolve 0.005mol acrylic acid in absolute ethanol solution at 60°C. Fully mix the ethanol solution of sodium dimethyl dithiocarbamate, the ethanol solution of thiosemicarbazide, the ethanol solution of o-phenanthroline and the ethanol solution of acrylic acid to obtain a mixed solution. Then the above mixed solution was added dropwise to NdCl 3 in anhydrous ethanol solution, stirred in an oil bath at 80°C for 6h and filtered, and the precipitate was washed with anhydrous ethanol, and placed in CaCl 2 Dry in a desiccant desiccator at 20°C to constant mass to obtain a light blue powder, which is the target product NdA 1 B 1 C 1.5 D. 0.5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com