Extrusion coating device for internal corrosion prevention of pipeline and coating method thereof

An internal anti-corrosion and pipeline technology, which is applied in the direction of devices and coatings that apply liquid to the surface, can solve the problems of difficult exit, easy deformation and damage under construction pressure, so as to achieve difficult deformation and damage, ensure coating quality, and pass the powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

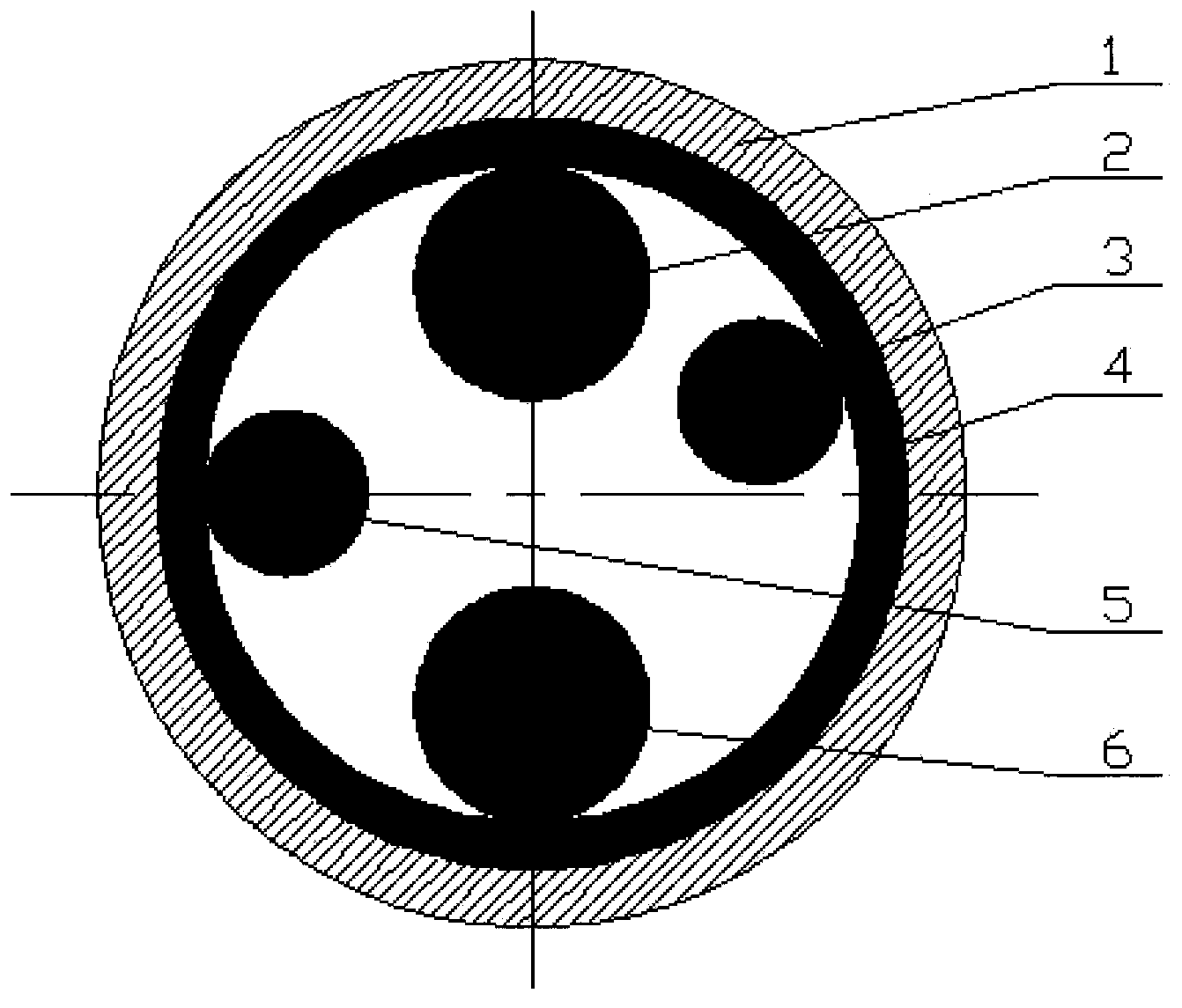

[0043] The hardness of the wear-resistant elastic rubber layer of the present invention is controlled by its thickness and composition ratio, and the specific weight ratio is as follows:

[0044] 35 parts of natural rubber, 15 parts of butadiene rubber, 10 parts of neoprene rubber, 15 parts of modified kaolin, 13 parts of white carbon black, 2 parts of stearic acid, 5 parts of titanium dioxide, 2 parts of magnesium stearate, antioxidant 4010NA 1.5 parts, 1 part of sulfur, 0.5 parts of accelerator DM.

[0045] The preparation process of the extrusion coating device for anti-corrosion in the pipeline of the present invention is as follows:

[0046] a. According to the above weight ratio, uniformly mix natural rubber, butadiene rubber, and neoprene; adopt the open mill mixing method, the mixing temperature is 50°C, and the roller speed is 16r / min.

[0047]b. After mixing in the open mill for 6 minutes, add them in sequence according to the order of active agent, anti-aging agent...

Embodiment 2

[0052] The raw material ratio of the wear-resistant elastic rubber layer is as follows:

[0053] 30 parts of natural rubber, 13 parts of butadiene rubber, 15 parts of neoprene rubber, 20 parts of nano-zinc oxide, 18 parts of white carbon black, 1.5 parts of stearic acid, 4 parts of white smoke, 3 parts of active agent AKT733 parts, 1 part of anti-aging agent RD , 0.8 parts of sulfur, 0.2 parts of accelerator NS.

[0054] The preparation process of the extrusion coating device for anti-corrosion in the pipeline of the present invention is as follows:

[0055] a. According to the above weight ratio, uniformly mix natural rubber, butadiene rubber, and neoprene; adopt the open mill mixing method, the mixing temperature is 45°C, and the roller speed is 17r / min.

[0056] b. After 7 minutes of mixing in the open mill, add in the order of active agent, anti-aging agent, accelerator, white carbon black, reinforcing agent, stearic acid, and vulcanization active agent, and carry out uni...

Embodiment 3

[0060] The raw material ratio of the wear-resistant elastic rubber layer is as follows:

[0061] 40 parts of natural rubber, 10 parts of butadiene rubber, 13 parts of neoprene, 25 parts of attapulgite ore powder, 10 parts of white carbon black, 1 part of stearic acid, 3 parts of white smoke, 5 parts of magnesium oxide, anti-aging agent BLE 2.5 1 part, 2 parts of sulfur, 1 part of accelerator CZ.

[0062] The preparation process of the extrusion coating device for anti-corrosion in the pipeline of the present invention is as follows:

[0063] a. According to the above weight ratio, uniformly mix natural rubber, butadiene rubber, and neoprene; adopt the open mill mixing method, the mixing temperature is 55°C, and the roller speed is 14r / min.

[0064] b. After mixing in the mill for 5 minutes, add them in sequence according to the order of active agent, anti-aging agent, accelerator, white carbon black, reinforcing agent, stearic acid, and vulcanization active agent, and carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com