Halogen-free non-phosphorus high-flame-retardant rigid polyurethane foam insulation material and preparation method thereof

A foam insulation material, rigid polyurethane technology, applied in the field of flame-retardant rigid polyurethane foam insulation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

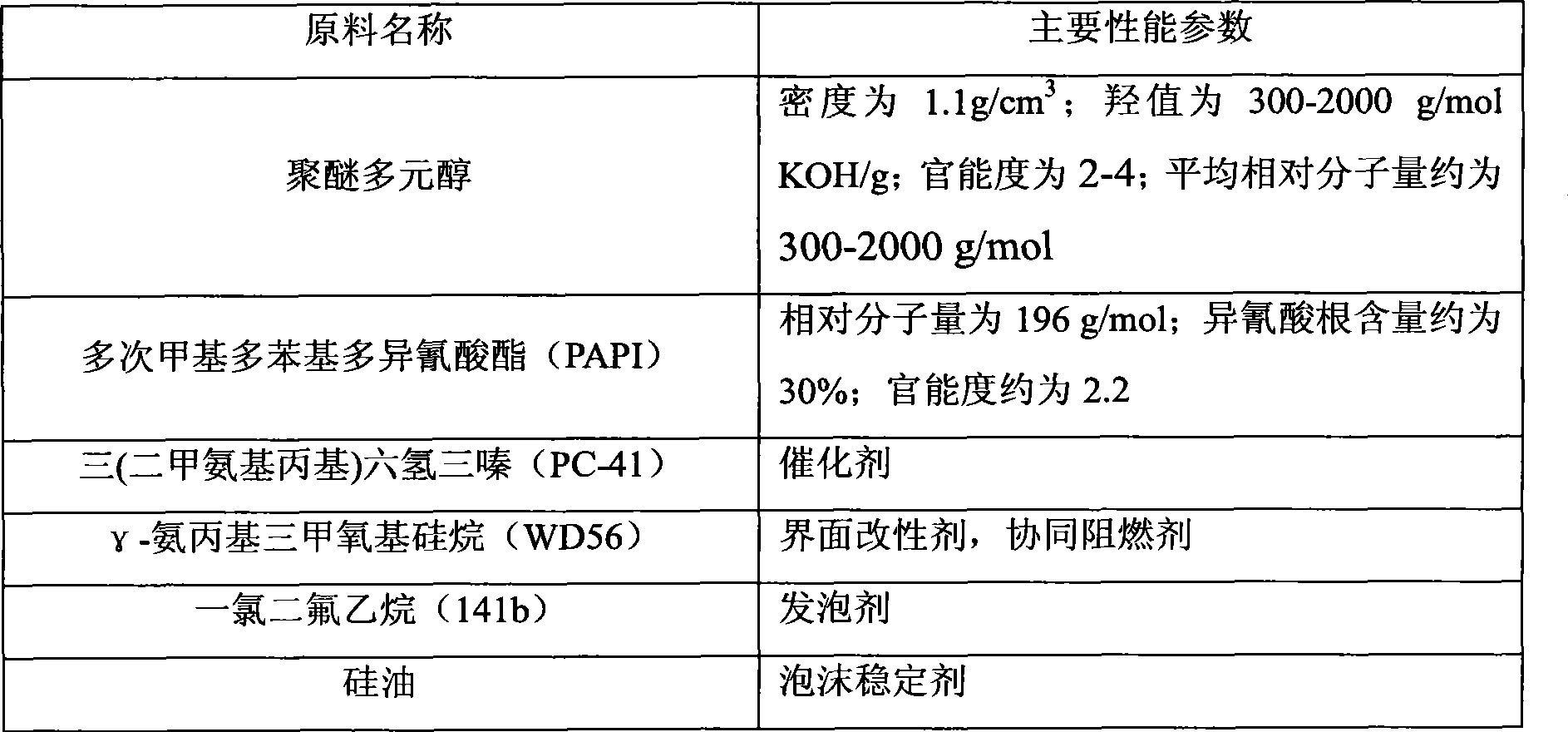

Method used

Image

Examples

Embodiment 1

[0032] 1.0 kg of polyethylene glycol with a hydroxyl value of 400 mg, 1.0 kg of expandable graphite with a particle diameter of 100 microns, 0.8 kg of aluminum hydroxide with a particle diameter of 1 micron, and 0.01 kg of tris(dimethylaminopropyl) hexahydrotriazine kg, 0.02 kg of silicone oil, 0.15 kg of γ-aminopropyltrimethoxysilane coupling agent, 0.05 kg of triethanolamine, and 0.6 kg of 141b foaming agent. After mixing, stir evenly at 25°C to form a combined white material . 2.0 kilograms of polymethyl polyphenyl polyisocyanates (PAPI) with an isocyanate content of 31% are mixed with 2.0 kilograms of aluminum hydroxide with a particle size of 10 microns, and stirred evenly at 35 ° C to form a combination black material. Quickly pour the above-mentioned combined white material and combined black material into the mold, and place it in a 70-degree oven for curing for 30 minutes to obtain a flame-retardant rigid polyurethane foam insulation material.

[0033] The limiting ...

Embodiment 2

[0047] 1.0 kg of polyethylene glycol with a hydroxyl value of 400 mg, 0.7 kg of expandable graphite with a particle size of 1 micron, 0.01 kg of tris(dimethylaminopropyl)hexahydrotriazine, 0.02 kg of organic silicone oil, γ-aminopropyl After mixing 0.15 kg of trimethoxysilane coupling agent, 0.05 kg of triethanolamine, and 0.6 kg of 141b foaming agent, stir evenly under the condition of 25°C to form a combined white material. 2.0 kilograms of polymethyl polyphenyl polyisocyanates (PAPI) with an isocyanate content of 31% are mixed with 2.0 kilograms of magnesium hydroxide with a particle size of 100 microns, and stirred evenly at 35°C to form a combination black material. Quickly pour the above-mentioned combined white material and combined black material into the mold, and place it in a 100-degree oven for curing for 30 minutes to obtain a flame-retardant rigid polyurethane foam insulation material.

[0048] The limiting oxygen index of the above-mentioned flame-retardant rig...

Embodiment 3

[0053] 1.0 kg of polyethylene glycol with a hydroxyl value of 400 mg, 0.7 kg of expandable graphite with a particle size of 10 microns, 0.01 kg of tris(dimethylaminopropyl)hexahydrotriazine, 0.02 kg of organic silicone oil, γ-aminopropyl Mix 0.15 kg of methyldiethoxysilane, 0.05 kg of triethanolamine, and 0.6 kg of 141b blowing agent, and stir evenly at 25°C to form a combined white material. 2.0 kilograms of polymethyl polyphenyl polyisocyanates (PAPI) with an isocyanate content of 31% are mixed with 2.0 kilograms of aluminum hydroxide with a particle size of 100 microns, and stirred evenly at 35 ° C to form a combined black material. Quickly pour the above-mentioned combined white material and combined black material into the mold, and place it in a 50-degree oven for curing for 30 minutes to obtain a flame-retardant rigid polyurethane foam insulation material.

[0054] The limiting oxygen index of the above-mentioned flame-retardant rigid polyurethane foam insulation mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com