Bi-component coating unsaturated polyester resin and preparation method thereof

A polyester resin, unsaturated technology, applied in the field of organic polymer compound preparation, can solve the problems of affecting coating performance, coating strength decrease, short pot life, etc., to save resin consumption, excellent air-drying property, prolong activation period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

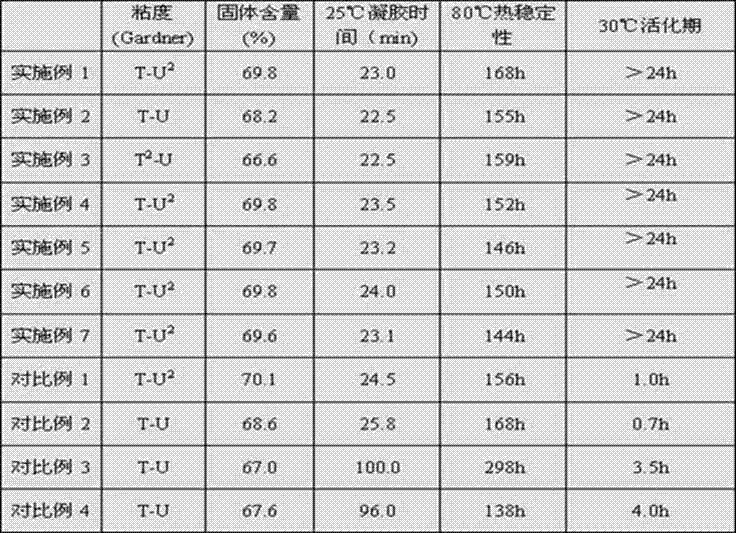

Examples

Embodiment 1

[0027] The preparation method of the unsaturated polyester resin for the two-component coating of this embodiment includes the following steps:

[0028] (1) Put 968.88g of diethylene glycol, 696.32g of pentaerythritol triallyl ether, and 1160.70 of fumaric acid into a four-neck reactor equipped with nitrogen protection device, agitator, thermometer and fractionating column device. g and 1.057 g of methyl hydroquinone, the temperature was raised to 180° C., and the polycondensation dehydration reaction was carried out until the acid value was 25 mgKOH / g.

[0029] (2) Lower the product temperature to 140°C, and add 0.211 g of methylhydroquinone.

[0030] (3) Add 1055.26 g of styrene cross-linking monomer to the product for dilution.

[0031] (4) After the dilution, reduce the temperature of the product to 40°C, add 0.141 g of 1,4-naphthoquinone and 0.141 g of p-benzoquinone, and mix them uniformly to obtain an unsaturated polyester resin for two-component coating.

[0032] The unsaturate...

Embodiment 2

[0035] The preparation method of the unsaturated polyester resin for the two-component coating of this embodiment includes the following steps:

[0036] (1) Put 182.62g of propylene glycol, 600.04g of trimethylolpropane diallyl ether, and 742.84 of diethylene glycol into a four-neck reactor equipped with a nitrogen protection device, agitator, thermometer, and fractionating column device. g, 1160.70 g of fumaric acid and 1.026 g of methyl hydroquinone, the temperature is raised to 170° C., polycondensation dehydration reaction is performed, and the acid value is 18 mgKOH / g.

[0037] (2) Lower the product temperature to 120°C, and add 0.205 g of methylhydroquinone.

[0038] (3) Add 1094.68g styrene cross-linking monomer to the product for dilution.

[0039] (4) After the dilution, the temperature of the product is reduced to 40°C and 0.205g of 1,4-naphthoquinone is added, and after mixing uniformly, the unsaturated polyester resin for two-component coating is obtained.

[0040] The unsa...

Embodiment 3

[0043] The preparation method of the unsaturated polyester resin for the two-component coating of this embodiment includes the following steps:

[0044] (1) Put 448.93g of propylene glycol, 248.28g of ethylene glycol, 365.82g of trimethylolpropane monoallyl ether, and tetramethylolpropane monoallyl ether into a four-neck reactor equipped with a nitrogen protection device, a stirrer, a thermometer, and a fractionating column device. 365.16 g of hydrogen phthalic anhydride, 118.49 g of phthalic anhydride, 666.81 g of maleic anhydride, and 0.308 g of hydroquinone were heated to 150° C. to perform polycondensation dehydration reaction to an acid value of 15 mgKOH / g.

[0045] (2) Reduce the product temperature to 140°C, add 0.246g tert-butyl hydroquinone,

[0046] (3) Add 1047.55g of styrene crosslinking monomer to the product for dilution.

[0047] (4) After the dilution, the temperature of the product is lowered to 40°C and 0.1845 g of p-benzoquinone is added, and after mixing uniformly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com