Phase change thermal storage material used at medium temperature in industries and preparation method thereof

A phase change heat storage and medium temperature technology, which is applied in heat exchange materials, chemical industry, chemical instruments and methods, etc., can solve problems such as low thermal conductivity, and achieve the effects of improving bonding strength, low preparation cost and fast deposition rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Adipic acid is selected according to mass percentage: 90%, copper-coated carbon nanotubes 10%. Among them, adipic acid can be directly dried for 24 hours, while carbon nanotubes are firstly treated at 400°C for 30 minutes, then mixed with ethanol and then subjected to ultrasonic treatment for 40 minutes, and then copper-plated on the surface, and dried after copper-plating Copper-coated carbon nanotubes were obtained after 10 hours of treatment.

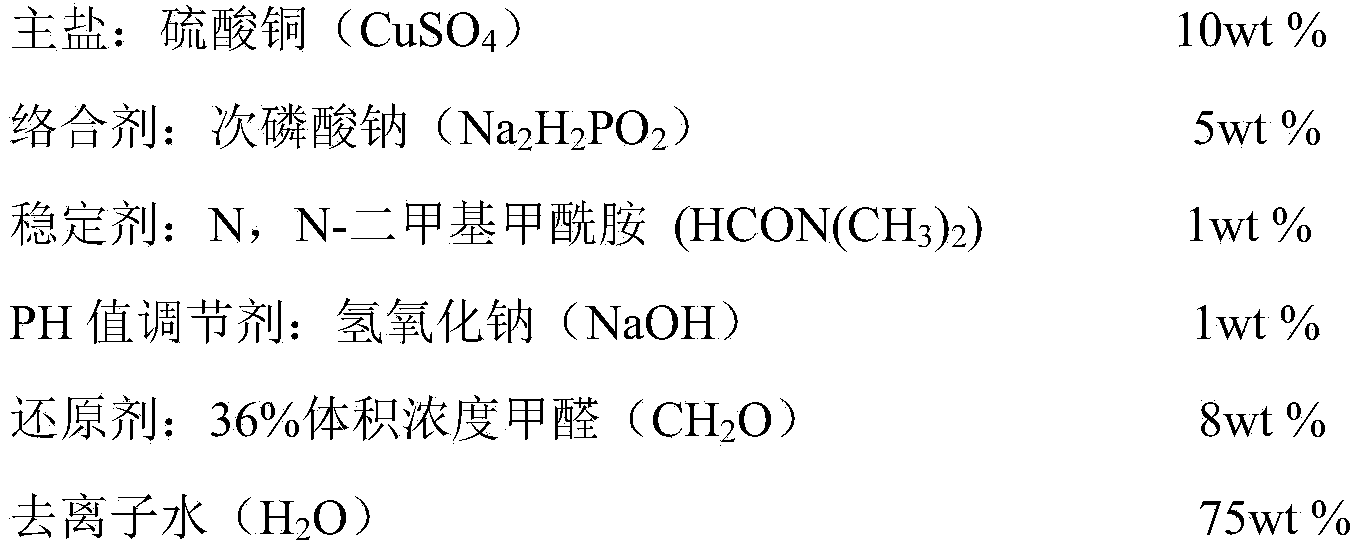

[0038] The process parameters during copper plating are as follows:

[0039]

[0040] Water bath temperature: 80±1℃

[0041] PH value: 12±0.1, adjusted with NaOH

[0042] Stirring method: magnetic stirring

[0043] Plating time: 0.5h.

[0044] figure 1 SEM image of copper-coated carbon nanotubes. From figure 1 It can be seen that the copper-plated layer on the surface of the carbon nanotubes is tightly attached to the surface of the carbon nanotubes.

[0045] Then, after adipic acid powder is ground through a 100-me...

Embodiment 2

[0048] Adipic acid is selected according to mass percentage: 92%, copper-coated carbon nanotubes 8%. Among them, adipic acid can be directly dried for 24 hours, while carbon nanotubes are first treated at 400 ° C for 30 minutes, then mixed with ethanol and then ultrasonically treated for 40 minutes, and then copper-plated on the surface (same as in Example 1) method), copper-coated carbon nanotubes were obtained after drying for 10 hours after copper plating.

[0049] The process parameters during copper plating are as follows:

[0050]

[0051] Water bath temperature: 80±1℃

[0052] PH value: 12±0.1, adjusted with NaOH

[0053] Stirring method: magnetic stirring

[0054] Plating time: 5h.

[0055] Then, after adipic acid powder is ground through a 100-mesh sieve, it is mechanically mixed with copper-coated carbon nanotubes for 15 minutes according to a predetermined ratio. under melt adsorption for 6 hours. During tablet molding, add 3% CMC binder. The melting endot...

Embodiment 3

[0057] Adipic acid is selected according to mass percentage: 94%, copper-coated carbon nanotubes 6%. Among them, adipic acid can be directly dried for 24 hours, while carbon nanotubes are firstly treated at 400°C for 30 minutes, then mixed with ethanol and then subjected to ultrasonic treatment for 40 minutes, and then copper-plated on the surface, and dried after copper-plating Copper-coated carbon nanotubes were obtained after 10 hours of treatment.

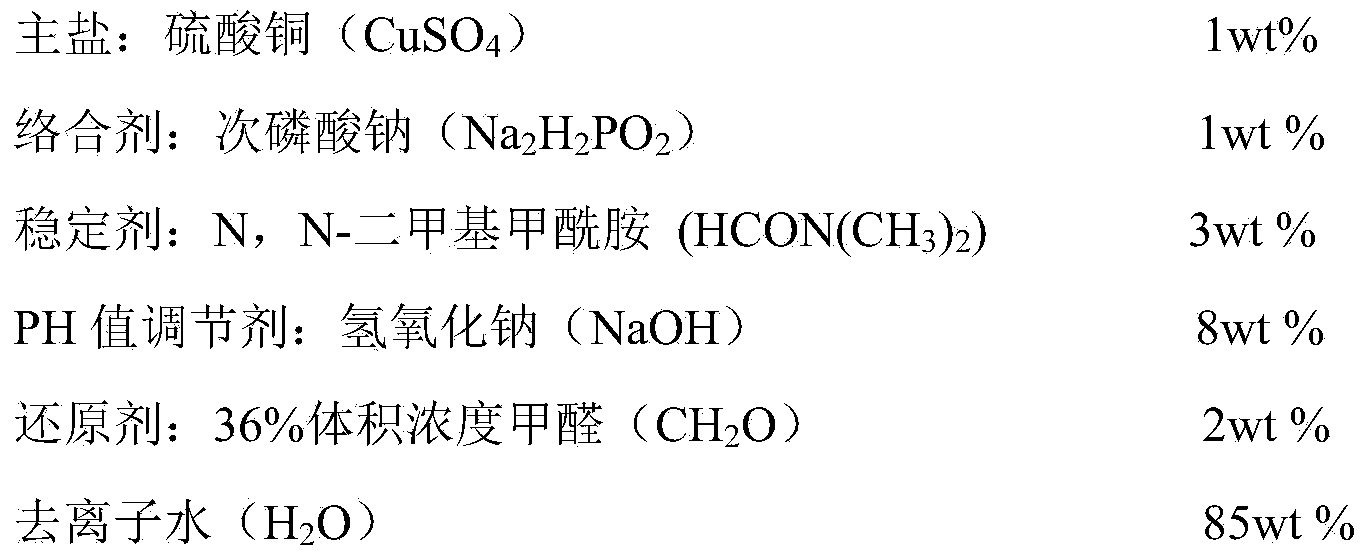

[0058] The process parameters during copper plating are as follows:

[0059]

[0060] Water bath temperature: 80±1℃

[0061] PH value: 12±0.1, adjusted with NaOH

[0062] Stirring method: magnetic stirring

[0063] Plating time: 3h.

[0064] Then, after adipic acid powder is ground through a 100-mesh sieve, it is mechanically mixed with copper-coated carbon nanotubes for 15 minutes according to a predetermined ratio. under melt adsorption for 6 hours. During tablet molding, add 3% CMC binder. The melting endothermic e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com