Molybdate passivation solution and method for passivating manganese metal by using molybdate passivation solution

A technology of passivating metals and molybdates, applied in the direction of metal material coating process, etc., to achieve the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Take ammonium molybdate, take triethanolamine and hydroxyhexylidene diphosphoric acid as a complexing agent, then mix ammonium molybdate and complexing agent with distilled water to form a passivation solution, and control the mass fraction of ammonium molybdate to 2.5% , the mass fraction of triethanolamine is 0.7%, and the mass fraction of hydroxyhexylidene diphosphoric acid is 0.1%;

[0018] (2) Soak and passivate the polished metal manganese sheet (irregular flake shape, but the working area is larger than 10mm×10mm) in the obtained passivation solution. The passivation temperature is controlled at 23°C, and the passivation time is 60s. Passivation solution pH6-7. After passivation, the metal manganese sheet was placed in the air to dry naturally (the laboratory temperature was 23°C).

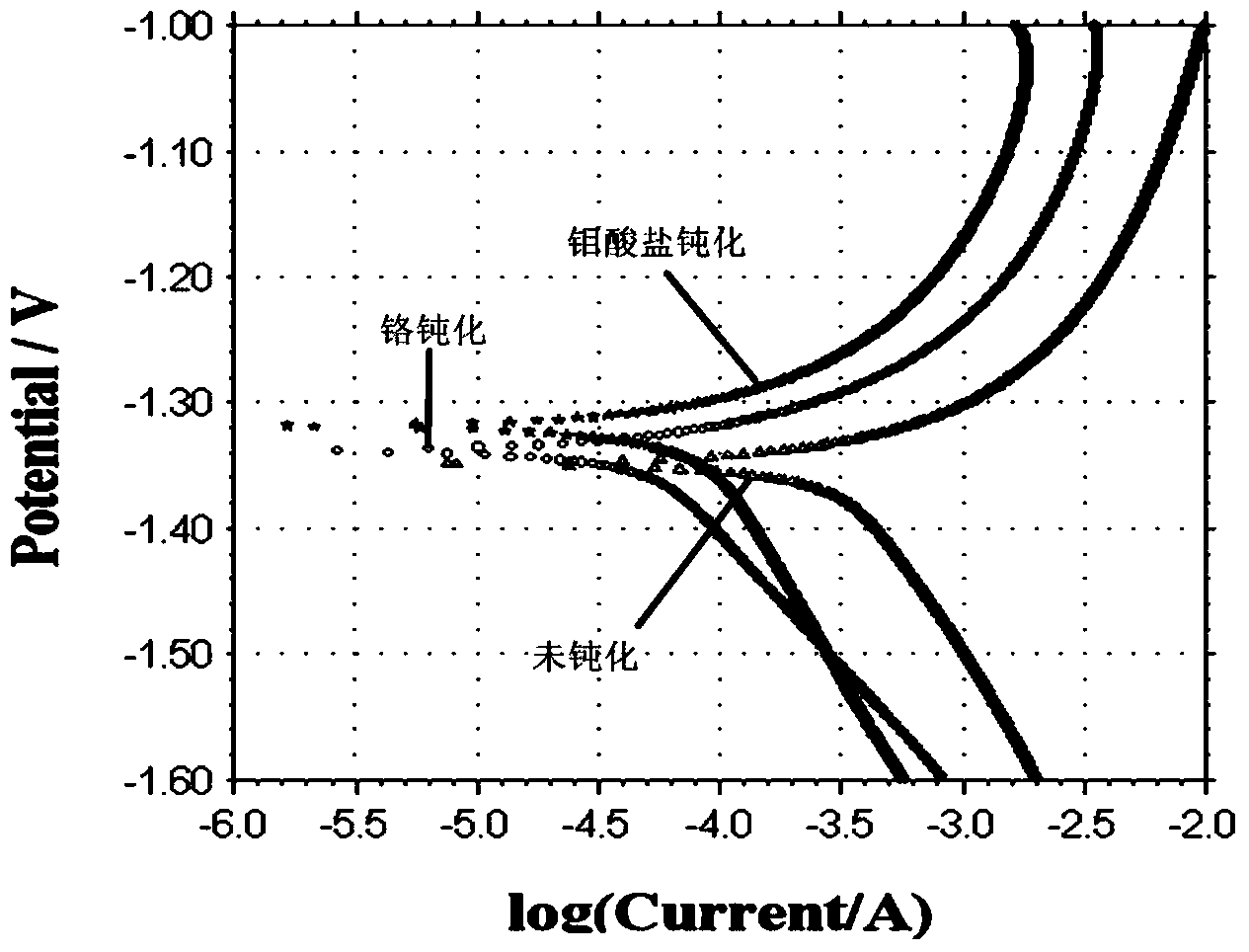

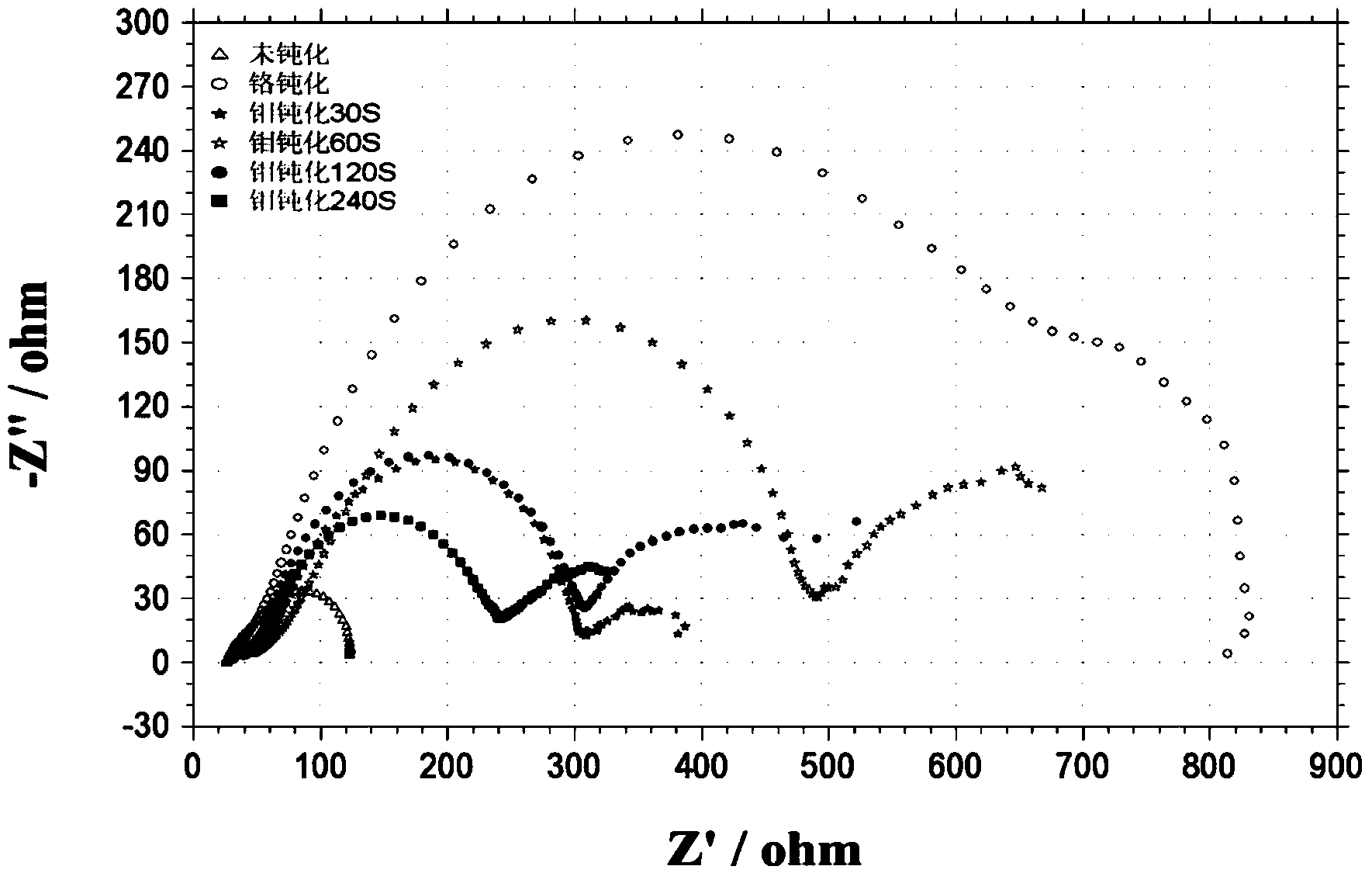

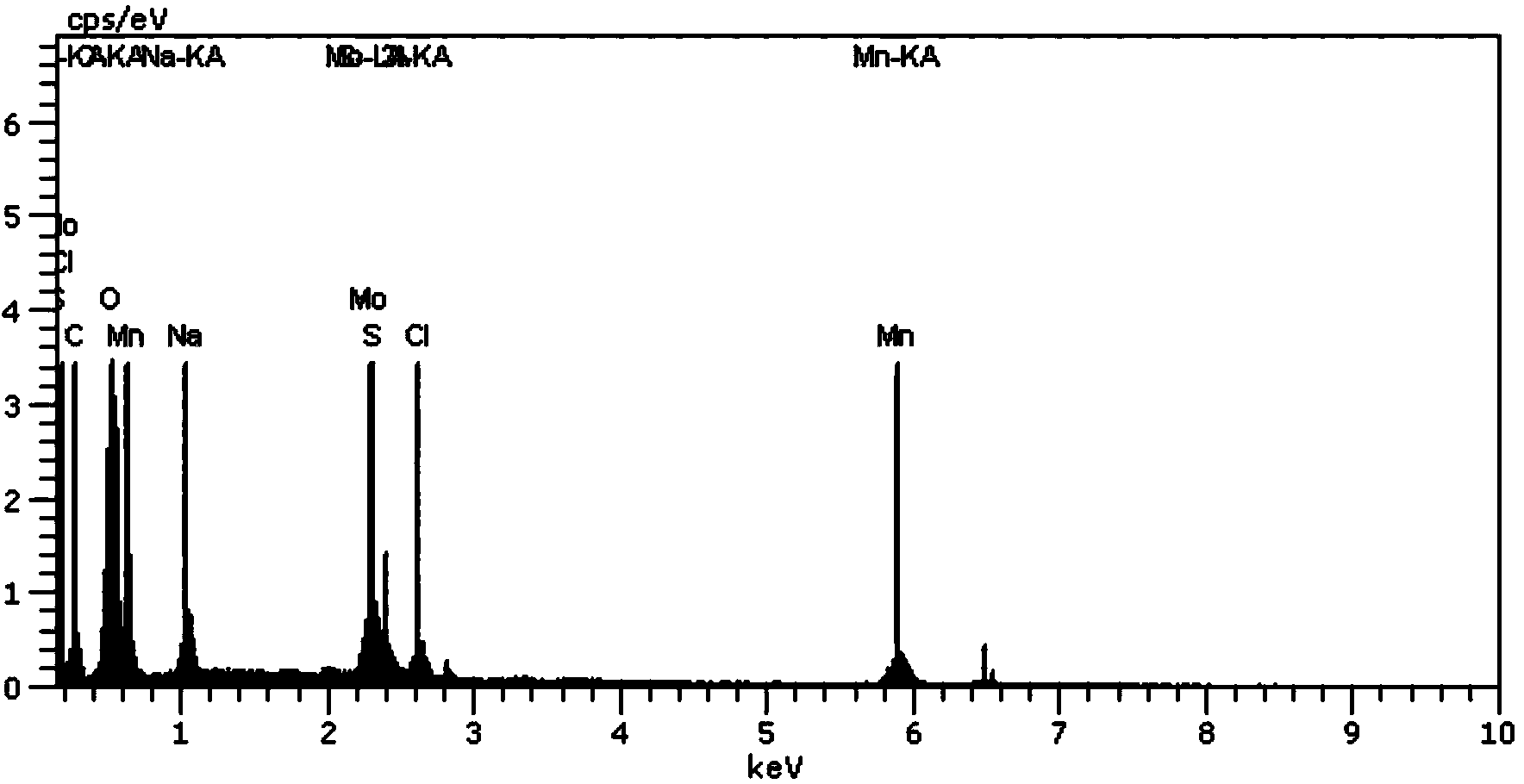

[0019] For the passivated metal manganese, the corrosion rate was calculated by dripping nitric acid-potassium permanganate, soaked in neutral salt water, the Tafel diagram and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com