A carburizing and quenching process for internal spline gears

A technology of carburizing and quenching and internal splines, which is applied in the coating process of metal materials, manufacturing tools, coatings, etc., can solve the problem of insufficient high-temperature cooling capacity of quenching oil, uneven distribution of quenching stress, and low fluidity in quenching oil, etc. problems, achieve the effects of small deformation, short steam film stage, and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

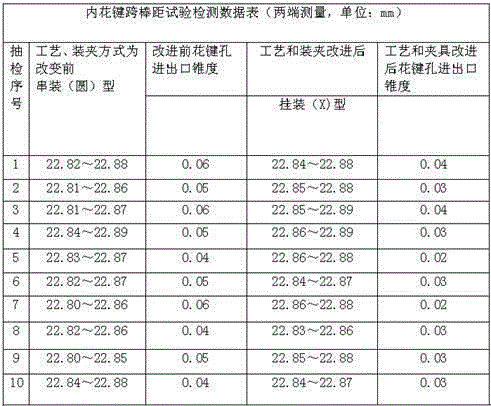

Image

Examples

Embodiment Construction

[0008] The preferred embodiments of the present invention are described in further detail.

[0009] A carburizing and quenching process for internal spline gears. The surface carburizing and quenching hardness of the selected internal spline gears is 56-62HRC, and the hardened layer depth is 0.7-1.1mm. Between, the tolerance is within 0.10mm. The process includes the following steps in turn: (1) The product is put into the furnace, the propane with a flow rate of 0.2~0.3m3 / h is introduced, and the furnace temperature is increased to 875~885°C. As the carburizing temperature increases, the plasticity of the steel The resistance decreases and the creep tendency of the workpiece increases, and the austenite grain size increases with the increase of carburizing temperature, which increases the deformation of the workpiece, so the carburizing temperature decreases from 920-930°C to 875-885°C (2) In the strong infiltration period, ensure that the furnace temperature is between 875~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com