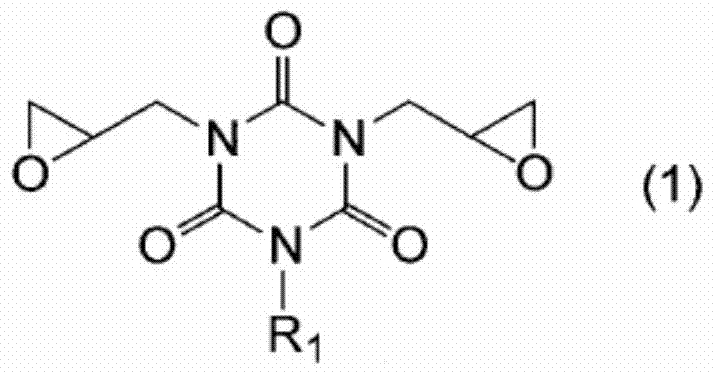

Composition for forming an antireflection film containing a reaction product of an isocyanuric acid compound and a benzoic acid compound

A technology of anti-reflection film and compound, which is applied in the field of composition forming the anti-reflection film, and can solve problems such as bad effects of processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

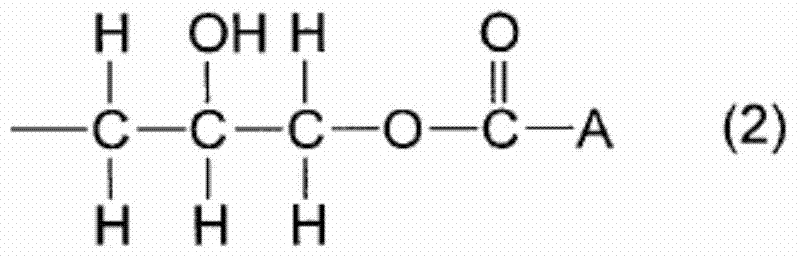

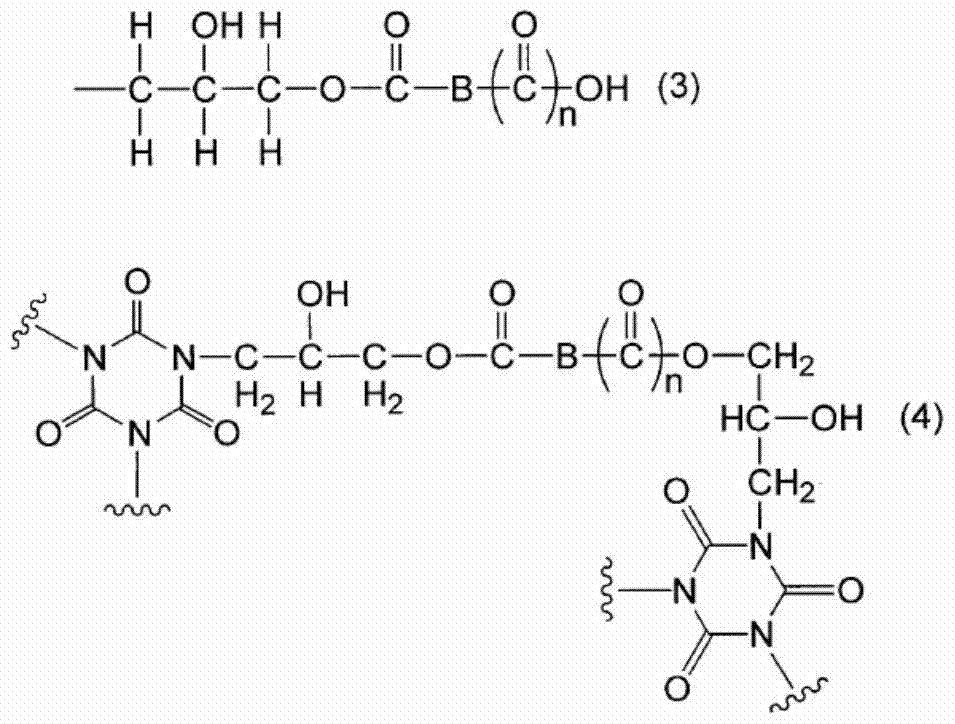

[0095] 175 g of tris(2,3-epoxypropyl)isocyanuric acid (manufactured by Nissan Chemical Industry Co., Ltd., trade name TEPIC), 628 g of 3,5-diiodo-2-hydroxybenzoic acid, and benzyl tris After dissolving 9.2 g of ethylammonium chloride in 3,250 g of propylene glycol monomethyl ether, it was reacted at 130° C. for 24 hours to obtain a solution containing a reaction product. In addition, it is considered that the reaction product contains an isocyanuric acid compound obtained by converting a 2,3-epoxypropyl group into a group of formula (5) and an oligomer (or polymer) having a structure of formula (6). ).

[0096]

Synthetic example 2

[0098] Dissolve 457 g of tris(2,3-epoxypropyl)isocyanuric acid (manufactured by Nissan Chemical Industries, Ltd., trade name TEPIC), 407 g of 4-hydroxybenzoic acid, and 136 g of 4-cyanobenzoic acid in propylene glycol monomethyl 1000 g of base ether, and reacted at 130° C. for 24 hours to obtain a solution containing a reaction product. In addition, it is considered that the reaction product contains an isocyanuric acid compound in which a 2,3-glycidyl group is converted into a group of formula (7) or formula (8).

[0099]

Embodiment 1

[0101] 9.6 g of propylene glycol monomethyl ether, 65.8 g of ethyl lactate, and 0.11 g of triphenylhexafluorosulfonium antimonate as a photoacid generator were added to 23.3 g of a solution containing 4.7 g of the reaction product obtained in Synthesis Example 1. , 1.2 g of tetramethoxymethyl glycoluril (manufactured by Japan Cytech Indastres Co., Ltd. (former Mitsui Cytech Co., Ltd.), trade name Paudaring 1174) and 0.06 g of pyridinium p-toluenesulfonate were used to form a solution. Then, filtration was performed using a polyethylene microfilter with a pore diameter of 0.10 μm, and then a polyethylene microfilter with a pore diameter of 0.05 μm was used to prepare a solution of an antireflection film-forming composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com