Preparation method for moisture absorbing and keeping type packing and application of packing in production of reconstituted tobaccos by using paper-making method

A reaction and coating technology, which is applied in the preparation of tobacco, application, fibrous fillers, etc., can solve the problems of out-of-synchronization moisture absorption rate of reconstituted tobacco leaves and tobacco sheets, so as to reduce the difference in moisture absorption and retention performance, increase porosity, improve The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

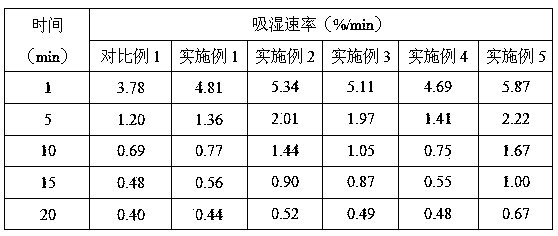

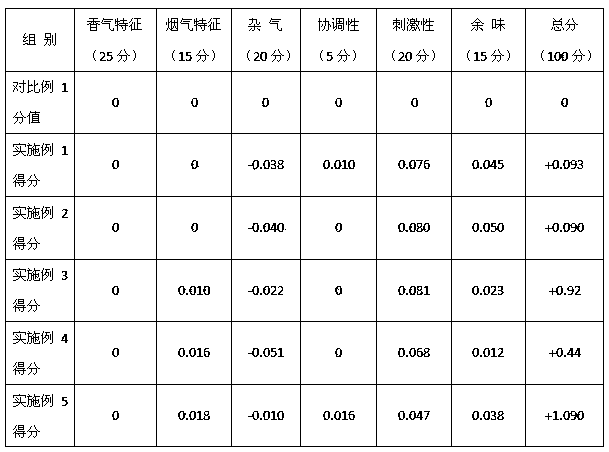

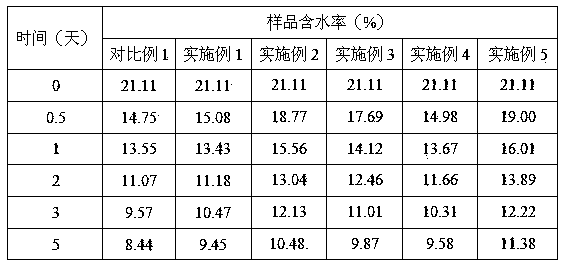

Examples

Embodiment 1

[0040] Weigh 1kg of 400 mesh kaolin, place it in a roasting furnace at 650°C for 3 hours, and after cooling, add 2kg of an alkaline solution with a concentration of 15% (potassium hydroxide: sodium hydroxide: potassium carbonate = 1:1: 0.2 (mass ratio), pH=10.4), reacted at 80°C for 4.5 hours, washed to pH=6.9 after the reaction, and dried at 115°C for 18 hours to obtain modified kaolin. Put the modified kaolin in a reaction kettle, add 10% of its mass raw konjac starch, mix well, add water and stir to obtain a mixed paste with a concentration of 45%, and react at 65°C for 1 hour. Then dry at 115° C. for 12 hours, and granulate to obtain a moisture-absorbing and moisturizing filler of 200 to 400 meshes.

[0041] The obtained filler is reconstituted tobacco leaf production process according to the existing papermaking method, and the moisture-absorbing and moisturizing filler is used as one of the fillers in the wet end papermaking, and the base sheet papermaking is carried out...

Embodiment 2

[0043] Weigh 1kg of 400 mesh kaolin, place it in a roasting furnace at 750°C for 5 hours, and after cooling, add 3kg of a 20% alkaline solution (potassium hydroxide: sodium hydroxide: potassium carbonate=2:1: 0.5 (mass ratio) pH=11.2), reacted at 85°C for 6 hours, washed at pH=7.4 after the reaction, and dried at 115°C for 18 hours to obtain modified kaolin. Put the modified kaolin in the reaction kettle, add 5% raw konjac starch, mix well, add water and stir to obtain a mixed paste with a concentration of 60%, and react at 50°C for 2.5 hours. Then dry at 115° C. for 12 hours, and granulate to obtain a moisture-absorbing and moisturizing filler of 200 to 400 meshes.

[0044] According to the existing paper-making method reconstituted tobacco leaf production process, the moisture-absorbing and moisturizing filler is used as one of the fillers in the wet-end papermaking process, and the base sheet papermaking is carried out according to the dry weight of the slurry at an amount of...

Embodiment 3

[0046] Weigh 1 kg of 400-600 mesh kaolin, place it in a roasting furnace at 850 ° C for 8 hours, and add 1.8 kg of alkaline solution with a concentration of 25% (potassium hydroxide: sodium hydroxide: potassium carbonate = 1 :2:0.7 (mass ratio) pH=12.1), react at 90°C for 9 hours, wash at pH=7.4 after the reaction, and dry at 115°C for 18 hours to obtain modified kaolin. Put the modified kaolin in the reaction kettle, add 1% konjac raw starch, mix thoroughly, add water and stir to obtain a mixed paste with a concentration of 58%, and react at 75°C for 0.5 hours. Then dry at 115°C for 12 hours and granulate to obtain a moisture-absorbing and moisturizing filler with a mesh size of 200-400.

[0047] According to the existing paper-making method reconstituted tobacco leaf production process, the moisture-absorbing and moisturizing filler is used as one of the fillers in the wet-end papermaking process, and the base sheet papermaking is carried out according to the dry weight of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com