Method for metallizing flexible PET-base ITO conductive layer and application of method

A conductive layer and metallization technology, which is applied in the field of chemical plating, can solve the problems of large differences in key groups on the surface and the inability to apply metallization on the conductive surface of conductive PET plastics, etc., to achieve clear wiring, wide fluctuation range of process parameters, and no overlap. The effect of line bridging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

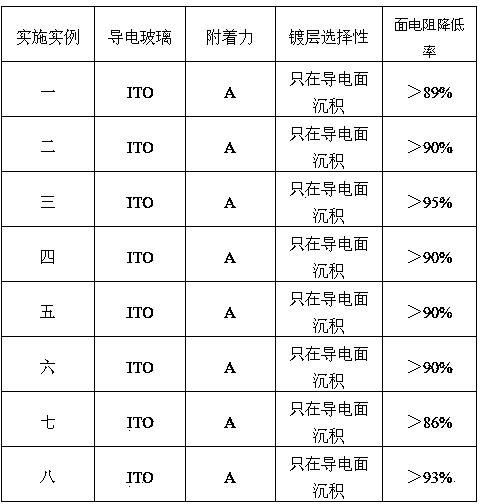

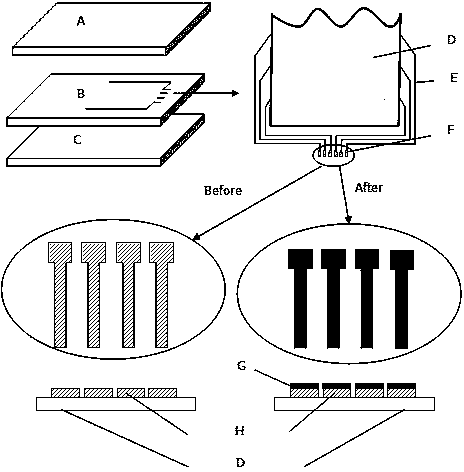

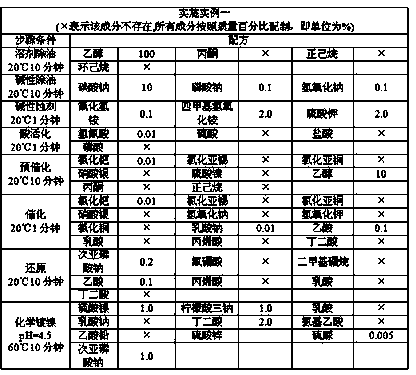

[0041] Implementation example of the present invention The specific implementation steps are: solvent degreasing—water washing—alkaline degreasing—water washing—alkaline etching—water washing—acid activation—water washing—precatalysis—water washing—catalysis—water washing—reduction—water washing—electroless nickel plating .

[0042] All formulas in the implementation examples of the present invention are configured according to mass percentage.

[0043] Specific implementation examples one to eight refer to the attached Figure 3 to Figure 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com