Copper foil excellent in adhesion to resin, method for producing same, and negative electrode material for printed wiring board or battery using the same

A technology of electrolytic copper foil and substrate, applied in non-aqueous electrolyte batteries, printed circuits, printed circuits, etc., can solve problems such as limited effect, increase peel strength, improve adhesion strength, and improve the roughening treatment layer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

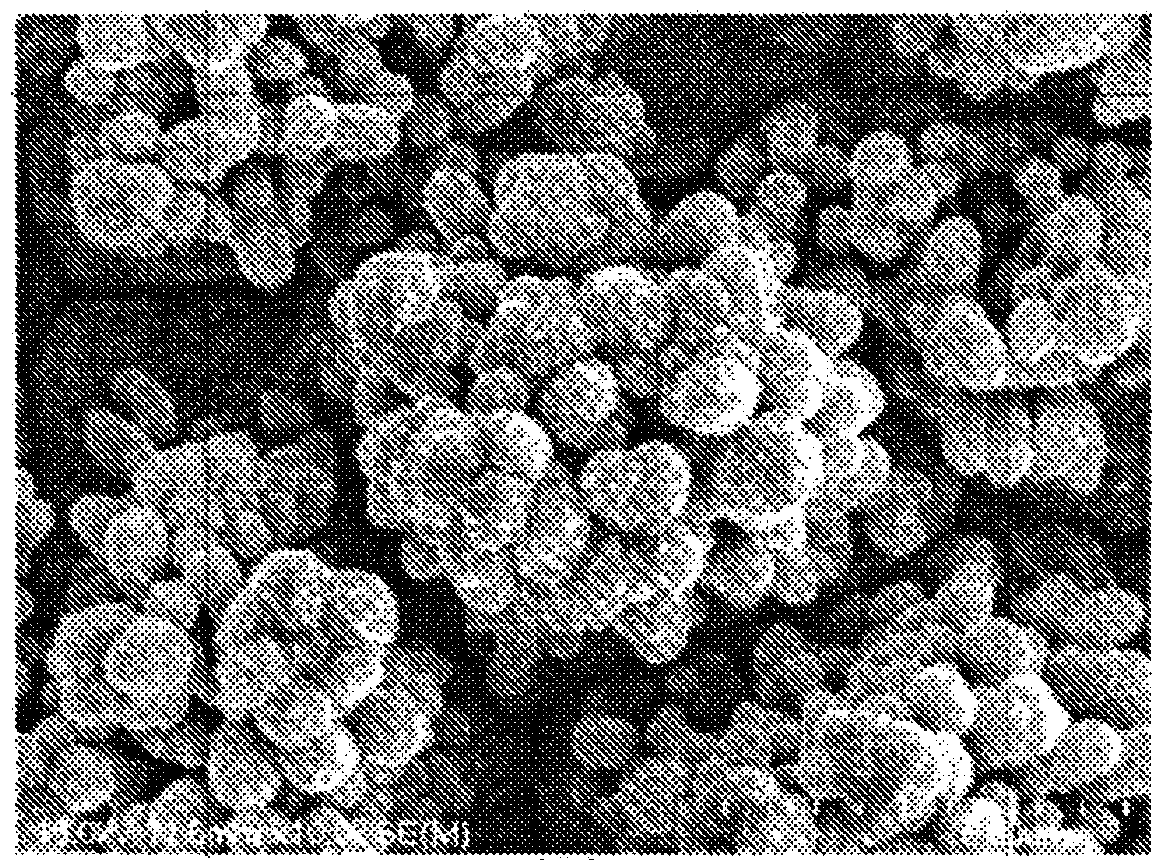

[0119] Using an IPC grade 3 electrolytic copper foil with a thickness of 12 μm, a treatment for forming roughened particles was performed on the rough surface of the copper foil.

[0120] The plating bath composition and electrolytic treatment conditions of the treatment (electroplating) electrolytic solution for forming roughened particles are as follows.

[0121] (Electrolyte composition)

[0122] Cu: 15g / L

[0123] h 2 SO 4 : 100g / L

[0124] W addition amount: 3mg / L (added in the form of sodium tungstate dihydrate, the same below)

[0125] Addition of sodium lauryl sulfate: 4mg / L

[0126] (Electrolyte temperature) 38°C

[0127] (current condition)

[0128] Current density: 54A / dm 2

[0129] Next, on the above-mentioned roughened surface, plating is performed with an electrolytic bath containing sulfuric acid / copper sulfate in order to prevent falling off of roughened particles and to increase peel strength. The processing conditions for plating are as follows.

...

Embodiment 2

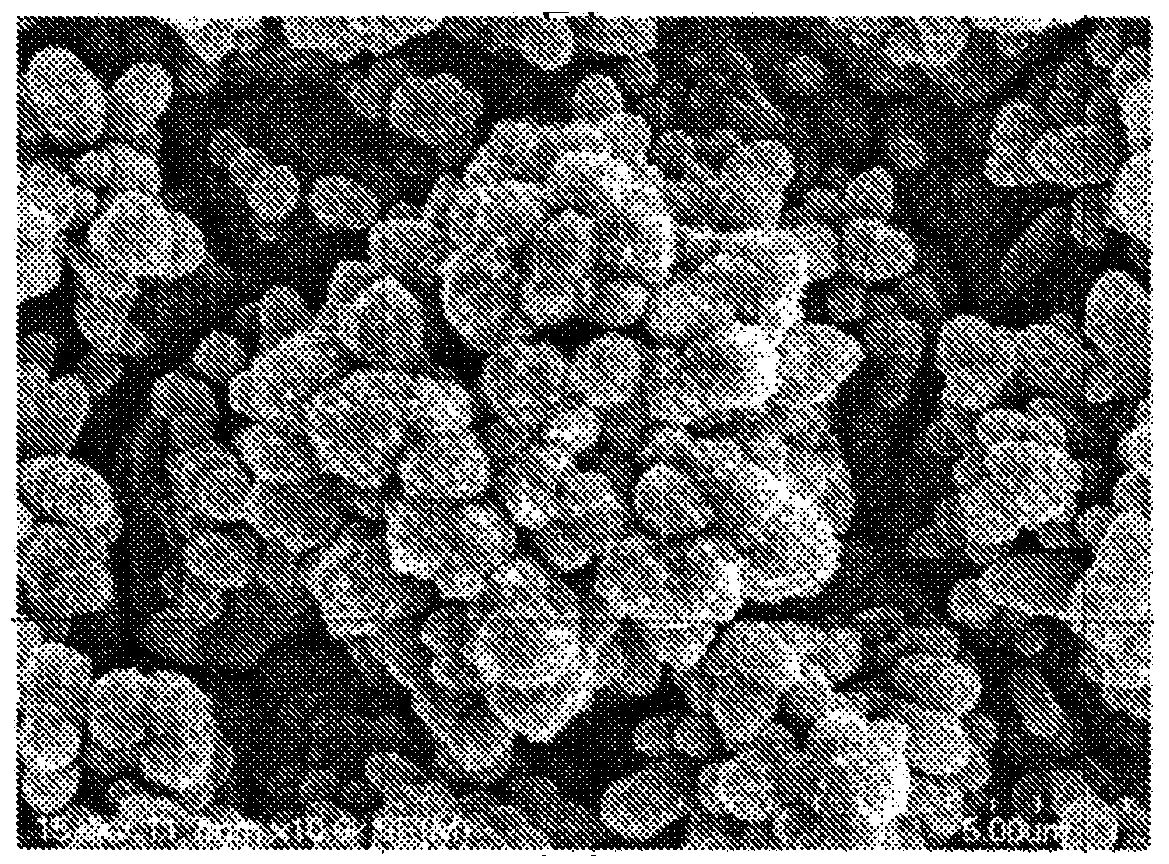

[0150] Using an IPC grade 3 electrolytic copper foil with a thickness of 12 μm, a treatment for forming roughened particles was performed on the rough surface of the copper foil.

[0151] The plating bath composition and electrolytic treatment conditions of the electrolytic solution at the time of roughening particle formation treatment (electroplating) are as follows.

[0152] (Electrolyte composition)

[0153] Cu: 15g / L

[0154] h 2 SO 4 : 100g / L

[0155] W addition amount: 3mg / L (added in the form of sodium tungstate dihydrate, the same below)

[0156] Addition of sodium lauryl sulfate: 4mg / L

[0157] (Electrolyte temperature) 38°C

[0158] (current condition)

[0159] Current density: 54A / dm 2

[0160] Next, on the above-mentioned roughened surface, plating is performed with an electrolytic bath containing sulfuric acid / copper sulfate in order to prevent falling off of roughened particles and to increase peel strength. The processing conditions for plating are as f...

Embodiment 3

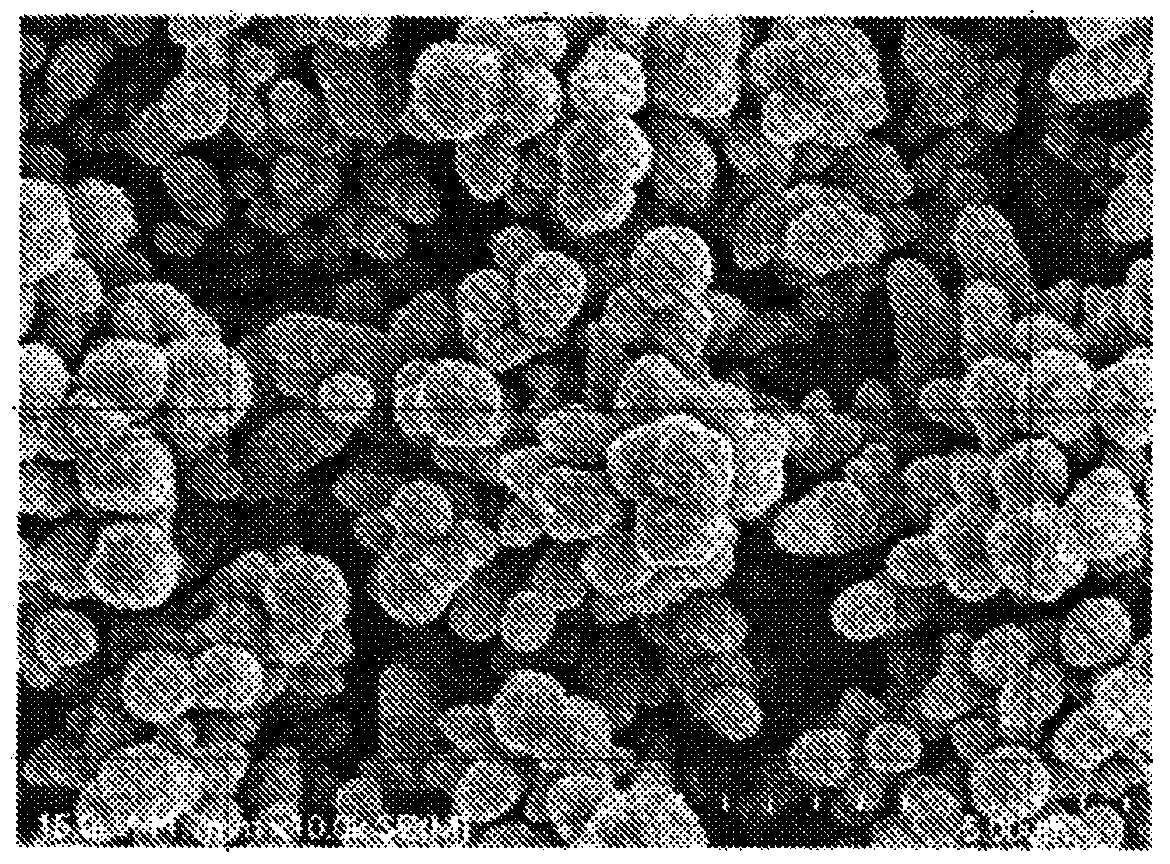

[0179] Using an IPC grade 3 electrolytic copper foil with a thickness of 12 μm, a treatment for forming roughened particles was performed on the rough surface of the copper foil.

[0180] The plating bath composition and electrolytic treatment conditions of the electrolytic solution at the time of roughening particle formation treatment (electroplating) are as follows.

[0181] (Electrolyte composition)

[0182] Cu: 20g / L

[0183] h 2 SO 4 : 100g / L

[0184] W addition amount: 3mg / L (added in the form of sodium tungstate dihydrate, the same below)

[0185] Addition of sodium lauryl sulfate: 4mg / L

[0186] (Electrolyte temperature) 38°C

[0187] (current condition)

[0188] Current density: 54A / dm 2

[0189] Next, on the above-mentioned roughened surface, plating is performed with an electrolytic bath containing sulfuric acid / copper sulfate in order to prevent falling off of roughened particles and to increase peel strength. The processing conditions for plating are as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com