Physical modification preparation method of high-solubility rice protein

A rice protein, physical modification technology, applied in the direction of plant protein processing, etc., can solve the problems of difficult to control the degree of hydrolysis, protein nutrition loss, performance improvement is not obvious, to improve the utilization rate and added value, wide application prospects, improve Sexually significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

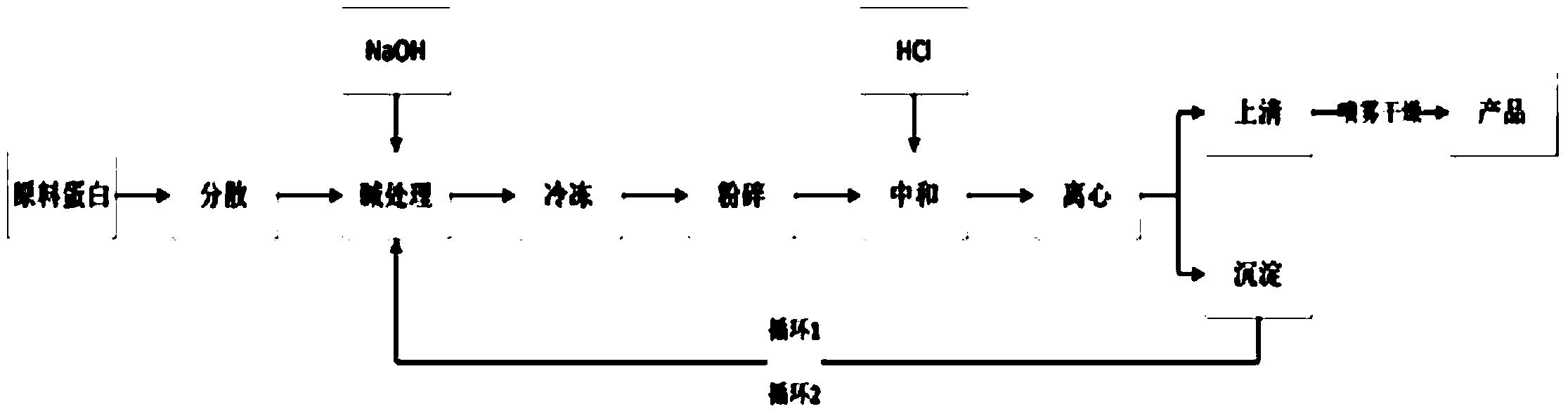

Method used

Image

Examples

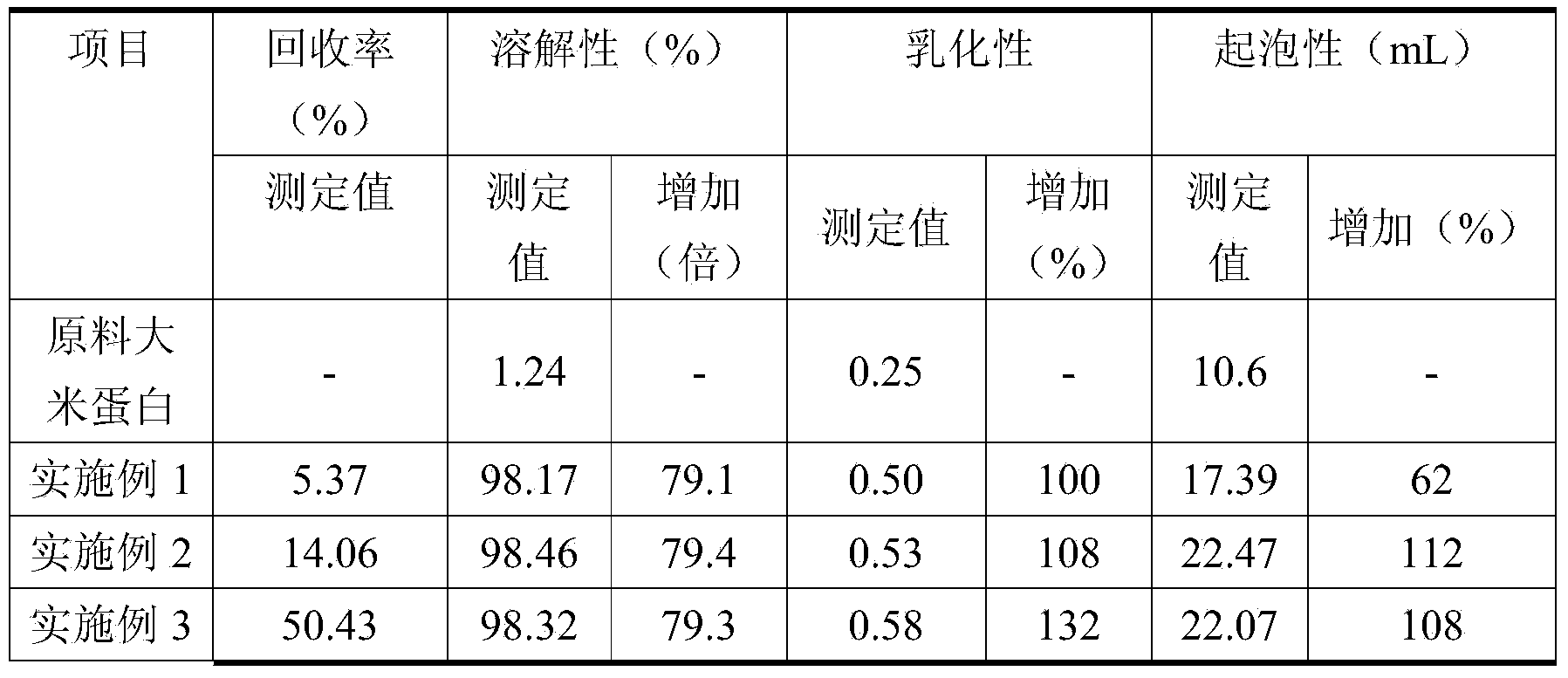

Embodiment 1

[0051] The method steps of this embodiment are as follows:

[0052] (1) Dispersion and alkali treatment: Disperse 1000g of raw rice protein in 15L of water, stir and mix well, and adjust the pH value of the obtained rice protein dispersion to 10.5 with NaOH solution;

[0053] (2) Freezing: freeze the feed liquid obtained in step (1) at -10°C until the feed liquid is completely frozen;

[0054] (3) Pulverization: pulverize the solid frozen feed liquid obtained in step (2) with a pulverizer until the solid becomes liquid completely;

[0055] (4) Acid neutralization: adjust the pH value of the feed solution obtained in step (3) to 7.0 with HCl solution;

[0056] (5) Centrifugation: centrifuge the feed liquid obtained in step (4) at 1000g for 10min, and collect the supernatant;

[0057] (6) Repeat: process the precipitate obtained in step (5) twice according to steps (1) to (5);

[0058](7) Drying: Combine the supernatant obtained in step (5) and step (6) and then spray dry. Du...

Embodiment 2

[0060] The method steps of this embodiment are as follows:

[0061] (1) Dispersion and alkali treatment: Disperse 1000g of raw rice protein in 20L of water, stir and mix well, and adjust the pH value of the obtained rice protein dispersion to 11.5 with NaOH solution;

[0062] (2) Freezing: Freeze the feed liquid obtained in step (1) at -15°C until the feed liquid is completely frozen;

[0063] (3) Pulverization: pulverize the solid frozen feed liquid obtained in step (2) with a pulverizer until the solid becomes liquid completely;

[0064] (4) Acid neutralization: adjust the pH value of the feed solution obtained in step (3) to 7.0 with HCl solution;

[0065] (5) Centrifugation: centrifuge the feed liquid obtained in step (4) at 1000g for 15min, and collect the supernatant;

[0066] (6) Repeat: process the precipitate obtained in step (5) twice according to steps (1) to (5);

[0067] (7) Drying: Combine the supernatant obtained in step (5) and step (6) and then spray dry. D...

Embodiment 3

[0069] The method steps of this embodiment are as follows:

[0070] (1) Dispersion and alkali treatment: Disperse 1000g of raw rice protein in 20L of water, stir and mix well, and adjust the pH value of the obtained rice protein dispersion to 11.5 with NaOH solution;

[0071] (2) Freezing: Freeze the feed liquid obtained in step (1) at -15°C until the feed liquid is completely frozen;

[0072] (3) Pulverization: pulverize the solid frozen feed liquid obtained in step (2) with a pulverizer until the solid becomes liquid completely;

[0073] (4) Acid neutralization: adjust the pH value of the feed solution obtained in step (3) to 7.0 with HCl solution;

[0074] (5) Centrifugation: centrifuge the feed liquid obtained in step (4) at 1000g for 15min, and collect the supernatant;

[0075] (6) Repeat: process the precipitate obtained in step (5) twice according to steps (1) to (5);

[0076] (7) Drying: Combine the supernatant obtained in step (5) and step (6) and then spray dry. D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com