Polyvinylidene fluoride/gold nanoparticle hybrid hollow fiber membrane and preparation method thereof

A technology of gold nanoparticles and polyvinylidene fluoride, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of catalytic activity decline and achieve equipment The effect of being simple, convenient for large-scale production, and easy for industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation of PVDF solution: PVDF is dissolved in DMF to obtain a 15Wt% polyvinylidene fluoride solution;

[0047] (2) Preparation of polymer gel: dissolve 50 g of polymer monomer (meth)acrylic acid or 4-vinylpyridine, 0.5 g of crosslinking agent MBAA and 0.5 g of initiator KPS in 1000 mL of water, and heat 1. Carry out radical polymerization for 8 hours under nitrogen protection conditions, centrifugal precipitation, and vacuum drying to obtain poly(meth)acrylic acid or poly-4-vinylpyridine gel;

[0048] (3) Preparation of polymer gel / gold nanoparticle hybrid: at 25°C, 20 g of the polymer gel obtained in step (2) was dispersed in 100 mL of deionized water, 1 g of chloroauric acid was added, and 1 g of sodium borohydride Reduction, centrifugal precipitation, and drying to obtain a polymer gel / gold nanoparticle hybrid;

[0049] (4) Preparation of polymer gel / gold nanoparticle hybrid dispersion: disperse the polymer gel / gold nanoparticle hybrid obtained in step (3) ...

Embodiment 2

[0056] (1) with embodiment 1;

[0057] (2) with embodiment 1;

[0058] (3) with embodiment 1;

[0059] (4) with embodiment 1;

[0060] (5) with embodiment 1

[0061] (6) Preparation of spinning solution: the polyvinylidene fluoride solution obtained in step (1), the polymer gel / gold nanoparticle hybrid dispersion obtained in step (4) and the pore-forming agent solution obtained in step (5) Mix according to mass ratio 80:20:0, dissolve, degas, obtain 15wt% spinning solution;

[0062] (7) with embodiment 1;

[0063] (8) with embodiment 1;

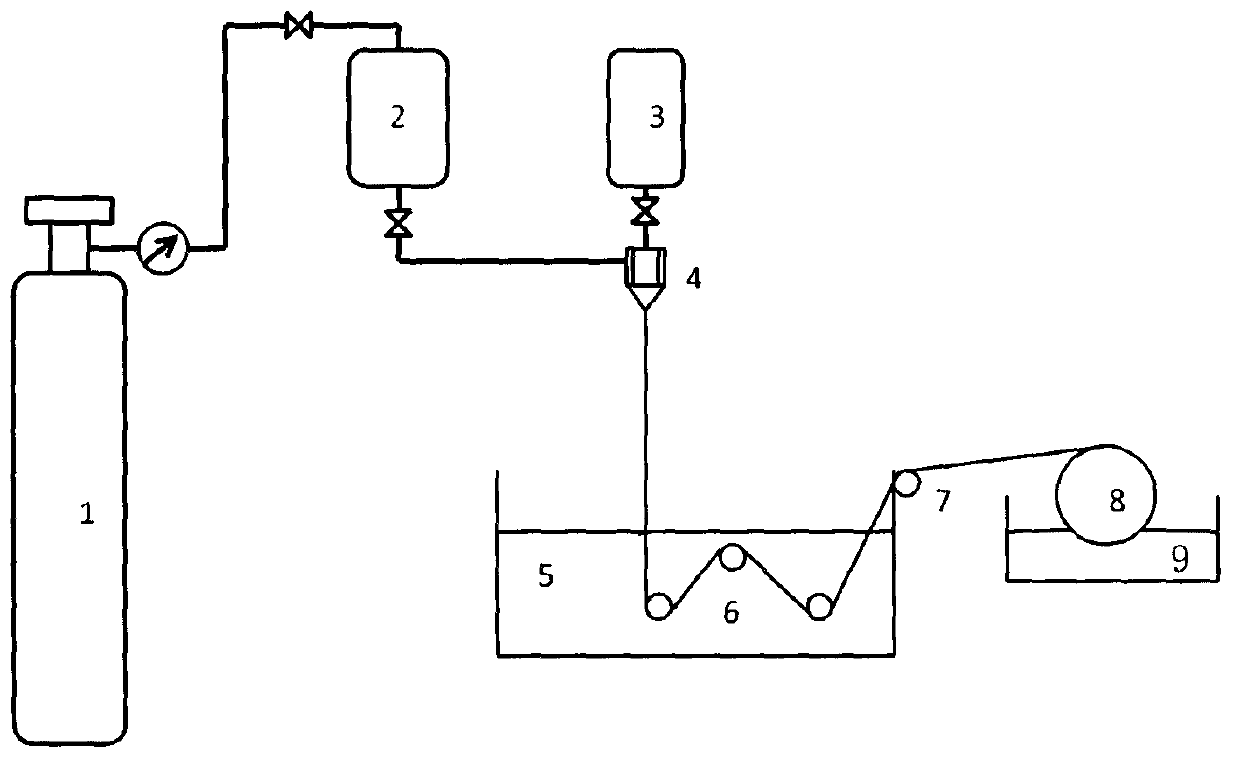

[0064] (9) Hybrid membrane preparation: adopt dry-wet spinning method, use hollow fiber spinning machine ( figure 1 ) and the core liquid prepared by the above step (7) and the coagulation bath prepared by the above step (8), in a dry spinning length of 10 cm, the temperature of the spinning solution is 50 ° C, and the temperature of the core liquid and the coagulation bath is 30 ° C. (6) The obtained spinning solution is spun to obtai...

Embodiment 3

[0066] (1) with embodiment 1;

[0067] (2) with embodiment 1;

[0068] (3) with embodiment 1;

[0069] (4) with embodiment 1;

[0070] (5) with embodiment 1;

[0071] (6) Preparation of spinning solution: the polyvinylidene fluoride solution obtained in step (1), the polymer gel / gold nanoparticle hybrid dispersion obtained in step (4) and the pore-forming agent solution obtained in step (5) Mix according to mass ratio 60:40:0, dissolve, degas, obtain 15wt% spinning solution;

[0072] (7) with embodiment 1;

[0073] (8) with embodiment 1;

[0074] (9) Hybrid membrane preparation: adopt dry-wet spinning method, use hollow fiber spinning machine ( figure 1 ) and the core liquid prepared by the above step (7) and the coagulation bath prepared by the above step (8), at a dry spinning length of 25 cm, a temperature of the spinning solution of 50 ° C, and a temperature of the core liquid and the coagulation bath of 30 ° C, the above steps (6) The obtained spinning solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com