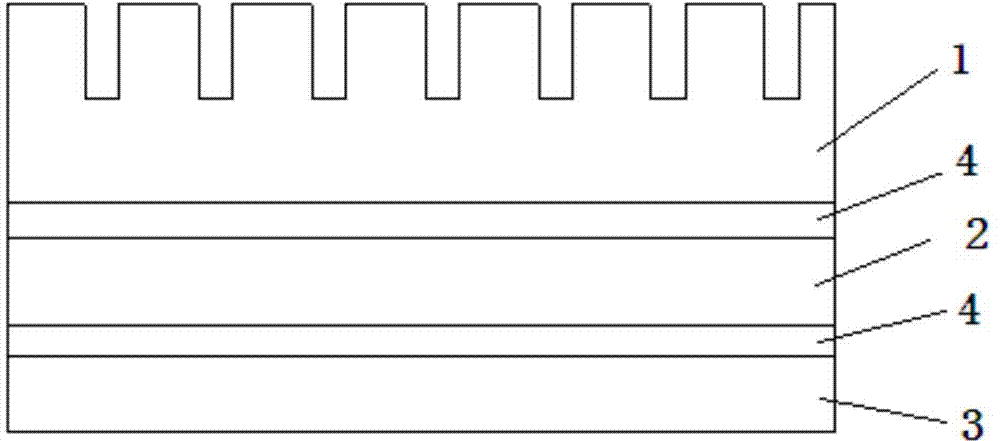

Polyurethane-material polishing pad and preparation method thereof

A polyurethane material, polishing pad technology, applied in grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting the transportation of polishing liquid, deterioration of polishing performance, increase of manufacturing cost, etc., to improve the decomposability of the environment , reliable performance, low manufacturing cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

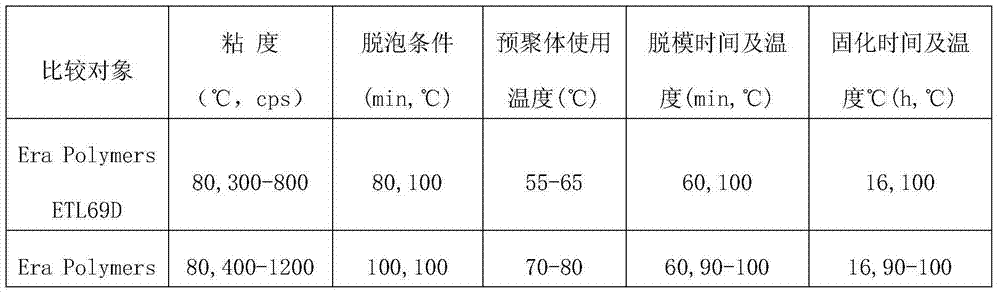

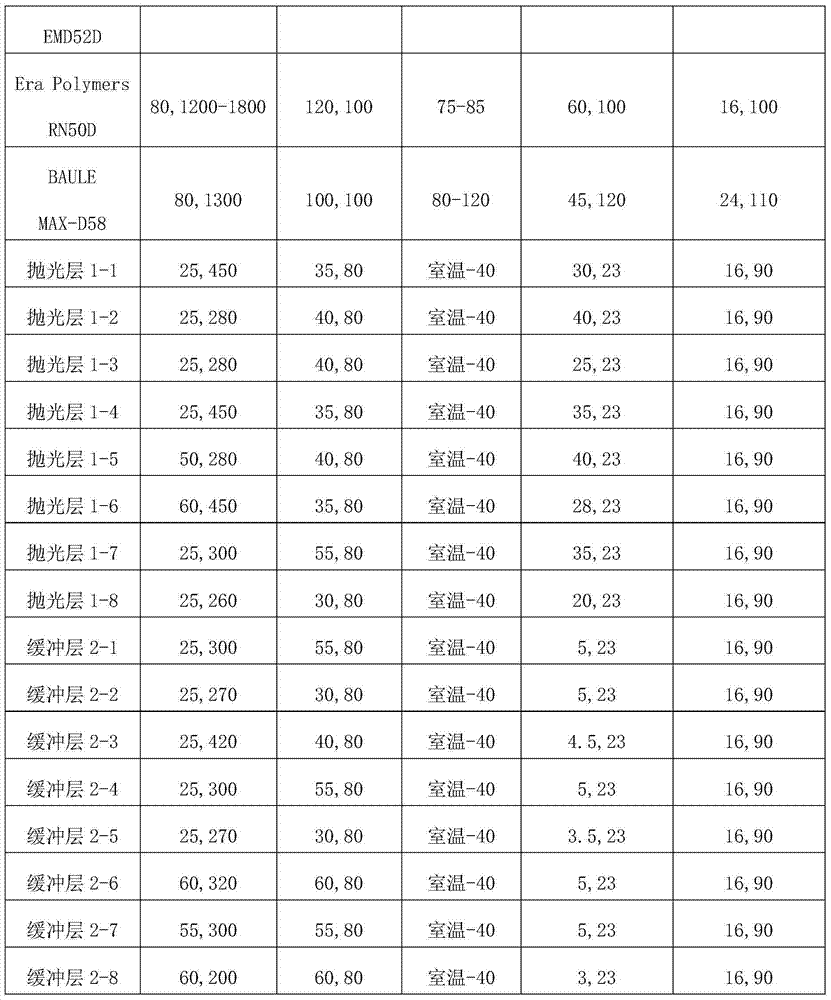

[0042] 100g of solid MDI was put into a 1L three-necked flask, the reaction temperature was raised to 70°C within 30 minutes, and after all the MDI was melted, the stirrer was started, and the stirring speed was 300 rpm. 12 g of dipropylene glycol was added dropwise to MDI, and the dropwise addition time was controlled at 1.5 hours. After the dropwise addition, the reaction was continued at 80°C for 2 hours, and then the reactant was subjected to defoaming treatment. The free NCO mass percentage is 23%, the viscosity is 320mPa·S, and the viscosity test temperature is 25℃.

preparation Embodiment 2

[0044] 100g of solid MDI was put into a 1L three-necked flask, the reaction temperature was raised to 75°C within 30 minutes, and after all the MDI was melted, the stirrer was started, and the stirring speed was 300 rpm. 30 g of dipropylene glycol was added dropwise to MDI, and the dropwise addition time was controlled at 1.5 hours. After the dropwise addition, the reaction was continued at 80°C for 2 hours, and then the reactant was subjected to defoaming treatment. The free NCO mass percentage is 11%, the viscosity is 450mPa·S, and the viscosity test temperature is 25℃.

Embodiment 3

[0046] 100g of solid MDI was put into a 1L three-necked flask, the reaction temperature was raised to 60°C within 30 minutes, and after all the MDI was melted, the stirrer was started, and the stirring speed was 300 rpm. 5 g of dipropylene glycol was added dropwise to MDI, and the dropwise addition time was controlled at 1.5 hours. After the dropwise addition, the reaction was continued at 80°C for 2 hours, and then the reactant was subjected to defoaming treatment. The free NCO mass percentage is 29%, the viscosity is 280mPa·S, and the viscosity test temperature is 25℃. Preparation Example 4 of Isocyanate Ion-terminated Energy-saving Prepolymer A

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com