Organic and inorganic composite coating and steel plate possessing coating thereof and manufacture method

An inorganic composite and manufacturing method technology, applied to chemical instruments and methods, coatings, devices for coating liquid on the surface, etc., can solve problems such as easy cracks, complex components, and difficult preparation, and achieve high ductility and low cost. Effect of low cost and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

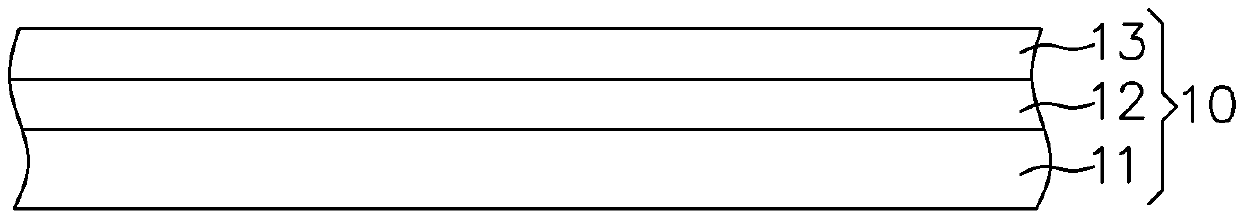

[0021] see figure 1 , which is a structural cross-sectional schematic view of the anti-fingerprint electrogalvanized steel sheet with an organic-inorganic composite surface transparent coating according to the present invention. The anti-fingerprint electrogalvanized steel sheet 10 of the present invention comprises: a first layer of steel sheet substrate 11, at least one second layer of electrogalvanized layer 12 which is arranged on at least one main surface of the first layer of steel sheet substrate 11 , and a third layer of organic-inorganic composite surface transparent coating 13 which is provided on the surface of the second layer of electro-galvanized layer 12 .

[0022] A preferred embodiment of the manufacturing method of the anti-fingerprint electrogalvanized steel sheet 10 with an organic-inorganic composite surface transparent coating of the present invention includes the following steps: (wherein, "wt%" represents "mass percentage")

[0023]An electrogalvanized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com