Method for preparing ethyl trifluoroacetate through continuous non-catalytic method

A technology of ethyl trifluoroacetate and trifluoroacetyl chloride, which is applied in the field of preparation of ethyl trifluoroacetate, can solve the problems of low product purity, uneconomical reaction, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

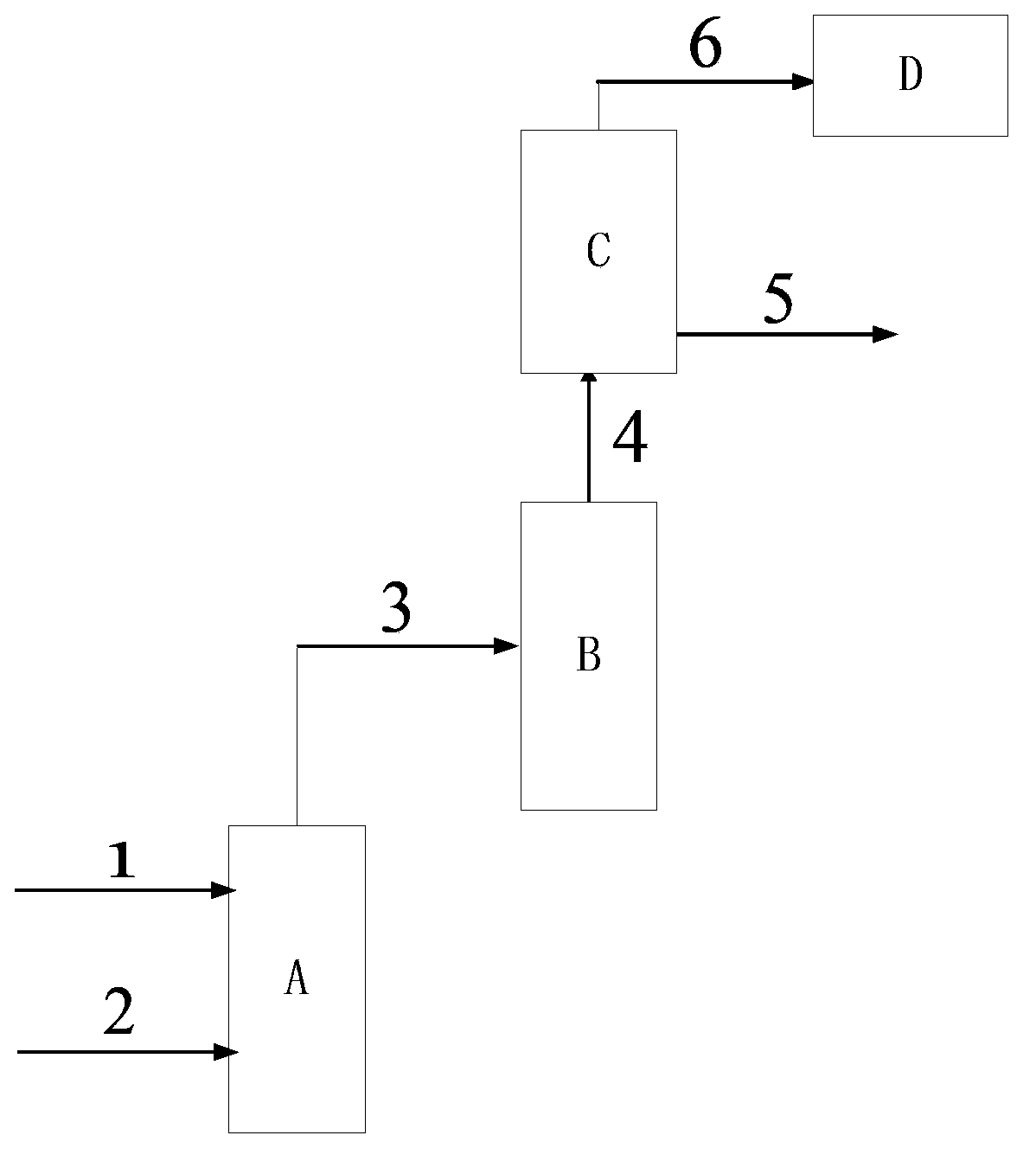

Method used

Image

Examples

Embodiment 1

[0034] The reactor is a three-necked flask with a volume of 250ml, equipped with stirring, a thermometer, an air guide tube, a dropping funnel and a rectification column, and the rectification column is connected with a condenser and an HCl absorption device. Add 38 g of ethanol into the reactor, and start feeding trifluoroacetyl chloride gas after the temperature rises to 35° C., keeping the feed rate of trifluoroacetyl chloride at 1 g / min. After reacting at 35°C for 60 minutes, start to add ethanol dropwise. The drop rate of ethanol is 0.22g / min. While adding dropwise, the temperature is gradually raised to 60°C, and the reaction distillation is carried out to rectify the generated ethyl trifluoroacetate. Go out, absorb hydrogen chloride gas with HCl absorption device, generate by-product hydrochloric acid. After 360 minutes of reactive distillation, a total of 415.3 g of rectified products were obtained. The purity of ethyl trifluoroacetate was 98.51% and the yield was 96.0...

Embodiment 2

[0036] The reactor is a three-necked flask with a volume of 250ml, equipped with stirring, a thermometer, an air guide tube, a dropping funnel and a rectification column, and the rectification column is connected with a condenser and an HCl absorption device. Add 38 g of ethanol into the reactor, and start feeding trifluoroacetyl chloride gas after the temperature rises to 20° C., keeping the feed rate of trifluoroacetyl chloride at 1 g / min. After reacting at 20°C for 65 minutes, start to add ethanol liquid dropwise. The drop rate of ethanol is 0.2g / min. Distill it out, absorb hydrogen chloride gas with an HCl absorption device, and generate hydrochloric acid as a by-product. After 360 minutes of reactive distillation, a total of 420.4 g of rectified products were obtained. According to chromatographic analysis, the purity of ethyl trifluoroacetate was 99.05%, and the yield was 97.75%.

Embodiment 3

[0038] The reactor is a three-necked flask with a volume of 250ml, equipped with stirring, thermometer, air duct and rectification column, and the rectification column is connected with a condenser and an HCl absorption device. Add 88g of ethanol into the reactor, and start to feed trifluoroacetyl chloride gas after the temperature rises to 40° C., the feeding speed of trifluoroacetyl chloride is 2 g / min. After reacting at 40°C for 60 minutes, start to add ethanol liquid dropwise. The drop rate of ethanol is 0.35g / min. Distill it out, absorb hydrogen chloride gas with an HCl absorption device, and generate hydrochloric acid as a by-product. After 145 min of reactive distillation, 421.3 g of the rectified product was obtained. The purity of ethyl trifluoroacetate was 98.52% and the yield was 97.43% according to chromatographic analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com