L-tryptophan double-effect continuous evaporation deamination process

A tryptophan deamination liquid and tryptophan technology are applied in the L-tryptophan double-effect continuous evaporation deamination process and the evaporation concentration deamination process of L-tryptophan fermentation filtrate, which can solve the problem of increasing Production costs, large steam consumption and other issues, to achieve energy saving, good deamination effect, high concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

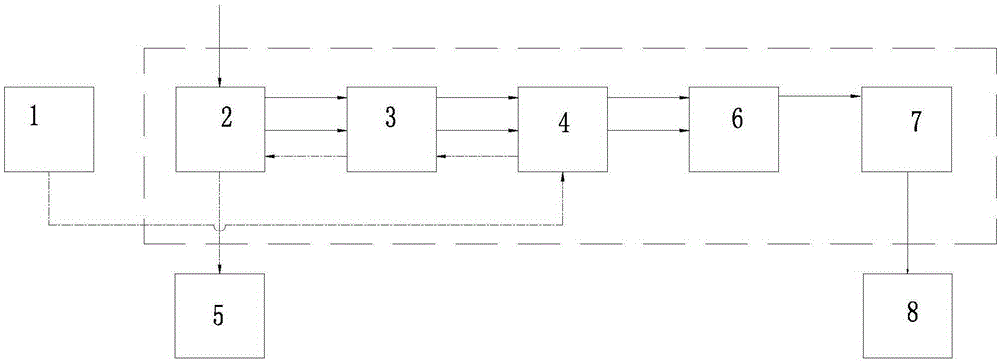

Image

Examples

Embodiment 1

[0020] Embodiment 1: a kind of L-tryptophan double-effect continuous evaporation deamination process, comprising the following process steps:

[0021] (1) After the L-tryptophan fermentation broth is sterilized, it enters the metal microfiltration membrane or ceramic membrane for microfiltration, ion exchange and other processes to remove impurities such as bacteria, protein and macromolecular pigments, and obtain clear L-tryptophan Amino acid filtrate, the mass percent concentration of L-tryptophan in the L-tryptophan filtrate is 2%, the temperature is 45°C, the free ammonia content is 1.0-1.2%, and the pH value is 9.5; the L - The tryptophan filtrate is sent into the feed buffer tank;

[0022] (2) Send the L-tryptophan filtrate in the feed buffer tank to the deamination tower to obtain the L-tryptophan deamination solution, the quality of L-tryptophan in the L-tryptophan deamination solution The percentage concentration is 2%, the temperature is 50°C, the free ammonia conte...

Embodiment 2

[0027] Embodiment two: a kind of L-tryptophan double-effect continuous evaporation deamination process, comprising the following process steps:

[0028] (1) After the L-tryptophan fermentation broth is sterilized, it enters the metal microfiltration membrane or ceramic membrane for microfiltration, ion exchange and other processes to remove impurities such as bacteria, protein and macromolecular pigments, and obtain clear L-tryptophan Amino acid filtrate, the mass percent concentration of L-tryptophan in the L-tryptophan filtrate is 2%, the temperature is 45°C, the free ammonia content is 1.0-1.2%, and the pH value is 9.5; the L - The tryptophan filtrate is sent into the feed buffer tank;

[0029] (2) Send the L-tryptophan filtrate in the feed buffer tank to the deamination tower to obtain the L-tryptophan deamination solution, the quality of L-tryptophan in the L-tryptophan deamination solution The percentage concentration is 1.9%, the temperature is 56°C, the free ammonia c...

Embodiment 3

[0034] Embodiment three: a kind of L-tryptophan double-effect continuous evaporation deamination process, comprising the following process steps:

[0035] (1) After the L-tryptophan fermentation broth is sterilized, it enters the metal microfiltration membrane or ceramic membrane for microfiltration, ion exchange and other processes to remove impurities such as bacteria, protein and macromolecular pigments, and obtain clear L-tryptophan Amino acid filtrate, the mass percent concentration of L-tryptophan in the L-tryptophan filtrate is 2%, the temperature is 45°C, the free ammonia content is 1.0-1.2%, and the pH value is 9.5; the L - The tryptophan filtrate is sent into the feed buffer tank;

[0036](2) Send the L-tryptophan filtrate in the feed buffer tank to the deamination tower to obtain the L-tryptophan deamination solution, the quality of L-tryptophan in the L-tryptophan deamination solution The percentage concentration is 1.8%, the temperature is 58°C, the free ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com