Inorganic-silicate fire-retardant coating and method for preparing inorganic-silicate fire-retardant coating

A technology of inorganic silicate and fire retardant coating, applied in the direction of alkali metal silicate coating, fire retardant coating, coating, etc., to achieve good fire and flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, the implementation of the present invention will be described in detail by means of the following specific examples. Those skilled in the art can easily understand the advantages and effects that the present invention can achieve through the contents of this description, and without departing from the spirit of the present invention Various modifications and changes are made in order to make or apply the teachings of the invention.

[0046] 1. the preparation method of inorganic silicate fireproof coating of the present invention

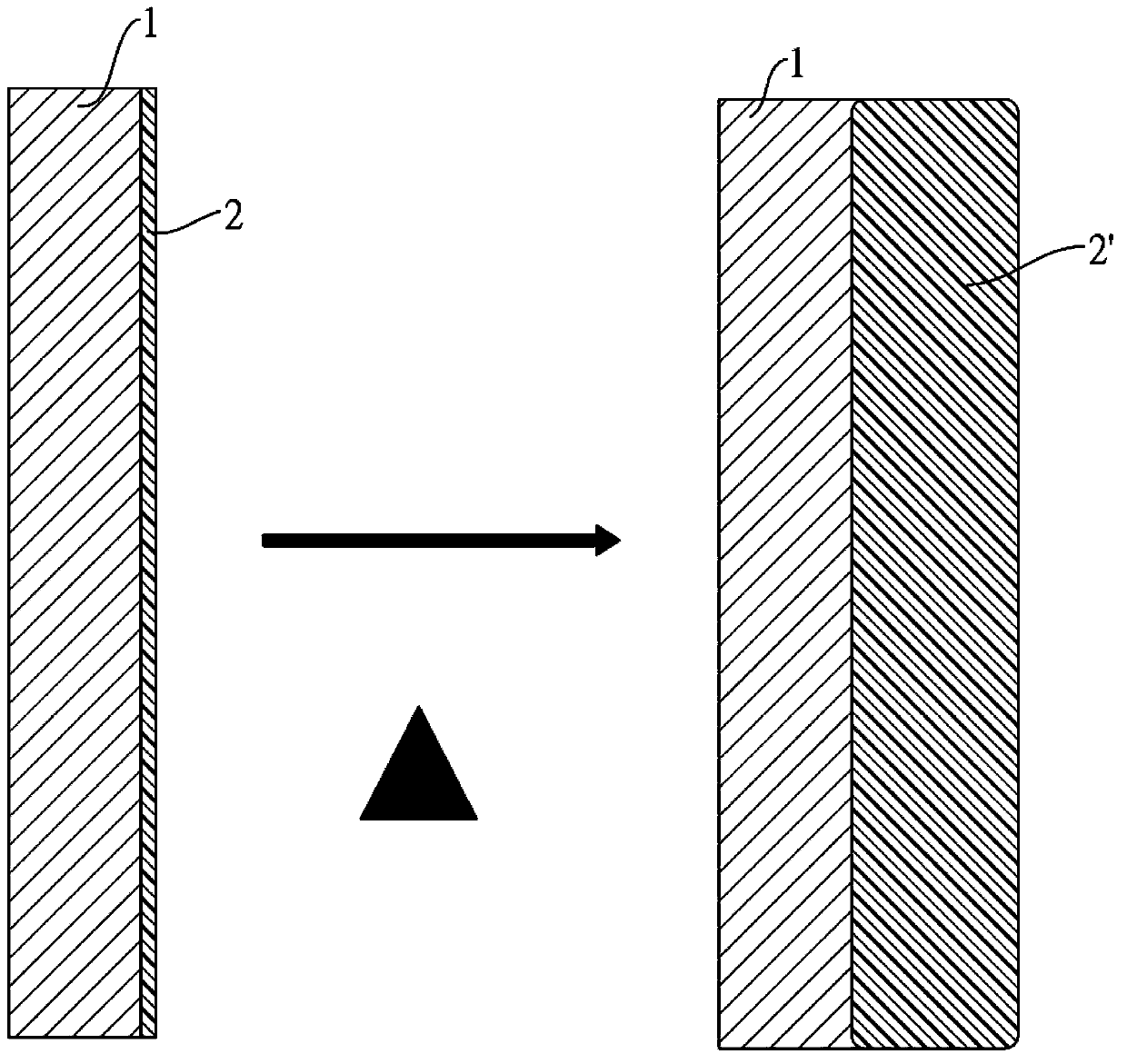

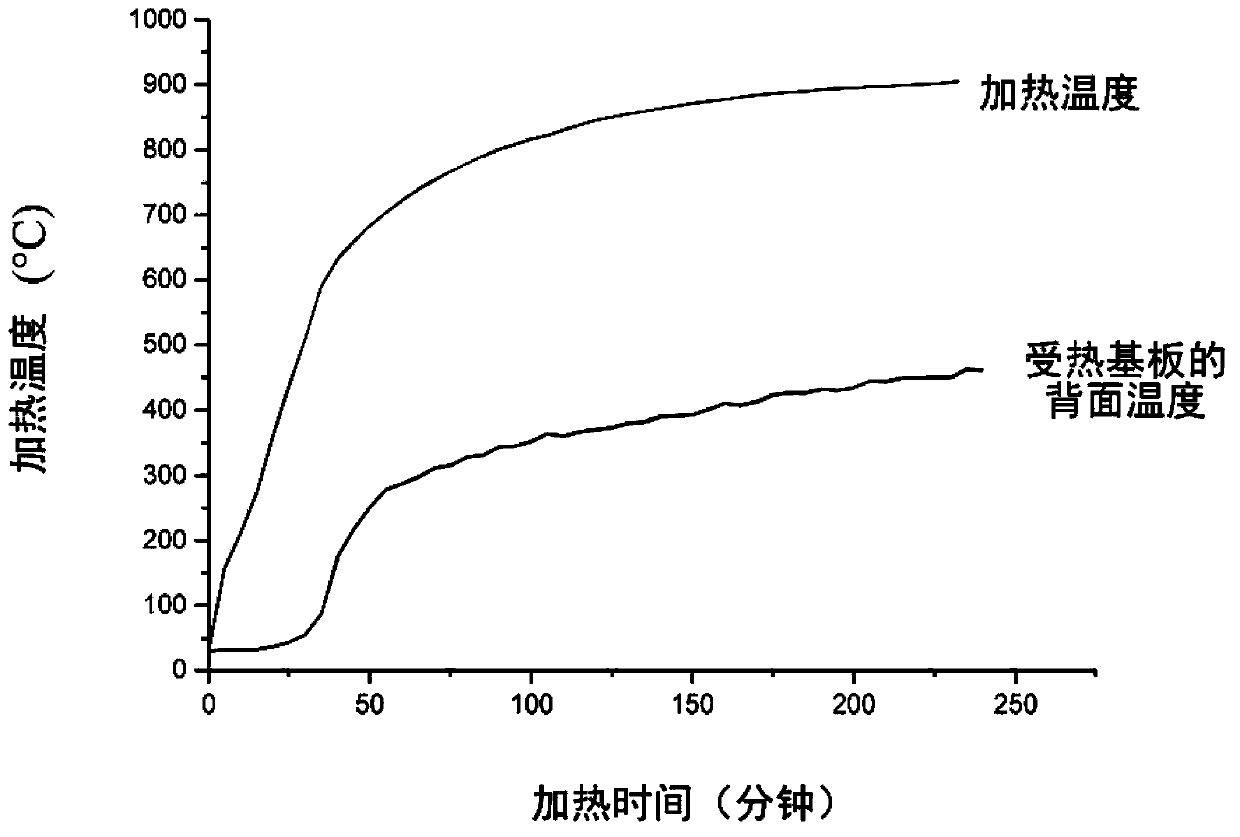

[0047] First, potassium silicate and water are placed in an autoclave with a vapor pressure of 5kg / cm 2 , and the temperature is 140° C., and it is prepared into a potassium silicate aqueous solution to obtain the inorganic silicate fireproof coatings of Examples 1 to 4 of the present invention. Here, the selected inorganic solvent is water.

[0048] The content of silicon dioxide and dipotassium monoxide, its weight ratio and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com