Environmental protection aging-resistance acrylate adhesive

A technology of epoxy acrylate and acrylate, which is applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve the problems of performance degradation and achieve excellent stiffness, excellent aging resistance, good shear strength and tensile strength intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An environment-friendly and aging-resistant acrylic adhesive, the formula ratio of which is as follows;

[0038] The weight ratio of the first component:

[0039] Tetrahydrofuryl methacrylate

30

tetrahydrofuryl acrylate

10

5

Triethylene glycol dimethacrylate

8

[0040] stearic acid methacrylate

5

epoxy methacrylate

10

Quinol

0.2

Antiaging agent 264

1

Nitrile rubber

7

Acrylonitrile-Butadiene-Styrene Copolymer

7

2

4

Cumene Hydroperoxide

4

[0041] The weight ratio of the second component:

[0042] Tetrahydrofuryl methacrylate

30

tetrahydrofuryl acrylate

10

5

Triethylene glycol dimethacrylate

8

stearic acid methacrylate

5

epoxy methacrylate

10

Nitrile rubber

7

...

Embodiment 2

[0056] An environment-friendly and aging-resistant acrylic adhesive, the formula ratio of which is as follows:

[0057] The weight ratio of the first component:

[0058] Tetrahydrofuryl methacrylate

33

octadecyl acrylate

8

6

16

epoxy methacrylate

12

p-tert-butylcatechol

0.4

Antiaging agent 264

1

7

Acrylonitrile-Butadiene-Styrene Copolymer

8

Nitrile rubber

5

4

[0059] The weight ratio of the second component:

[0060] Tetrahydrofuryl methacrylate

32

octadecyl acrylate

6

5

15

epoxy methacrylate

10

7

Acrylonitrile-Butadiene-Styrene Copolymer

8

10

Cobalt naphthenate

0.2

Aliphati...

Embodiment 3

[0076] An environmentally friendly and anti-aging acrylic adhesive consists of two components, wherein,

[0077] The first component comprises the following compositions and parts by weight:

[0078] Methacrylate or acrylate combined monomer 50, epoxy modified acrylate monomer 15, toughening agent 5, thickener 1, peroxide 1, stabilizer 0.1;

[0079] The second component includes the following composition and content in parts by weight: methacrylate or acrylate combined monomer 45, epoxy-modified acrylate monomer 15, toughening agent 5, thickener 1, adhesion tackifier 5. Accelerator composition 1.

[0080] The methacrylate or acrylate combination monomers used in the first component and the second component are all acrylate tetrahydrofuryl esters, the epoxy-modified acrylate monomers are all epoxy acrylates, and the toughening agents are all Neoprene, thickener are PMMA powder. The peroxide in the first component is selected from diacyl peroxide, and the stabilizer is a phos...

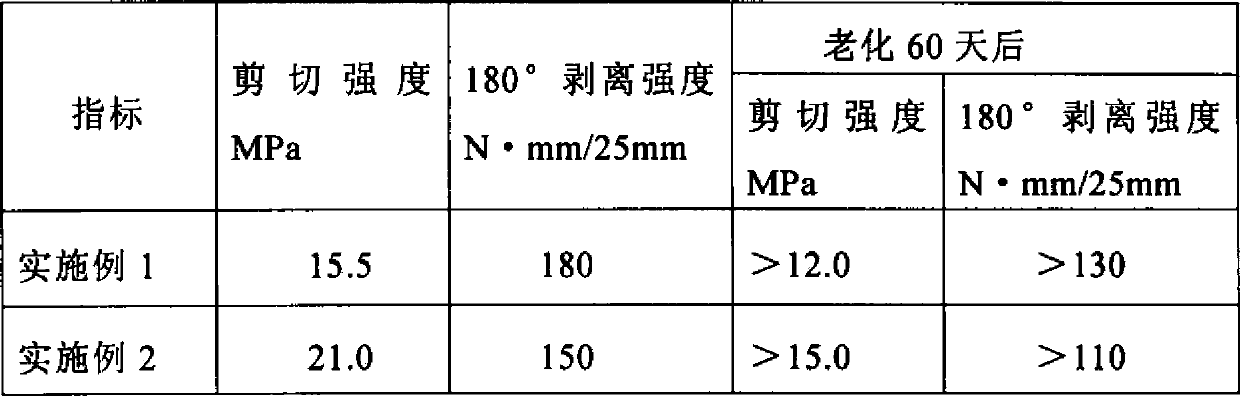

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com