Anisotropic conductive films, manufacturing method of same and semiconductor devices connected and manufacturing method

An anisotropic, conductive film technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as overflow, bubble generation, and the edge of the faulty adhesive layer, and achieve Effect of improving wettability, uniform pressure distribution, and improving connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

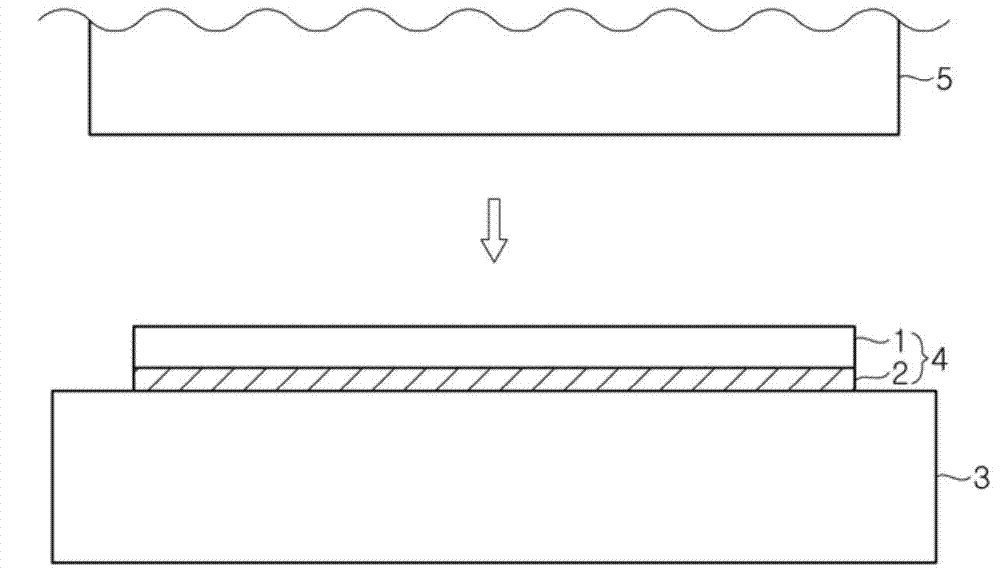

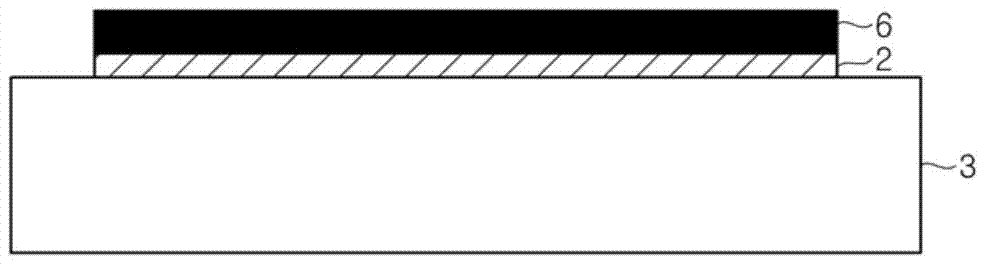

Method used

Image

Examples

Embodiment 1

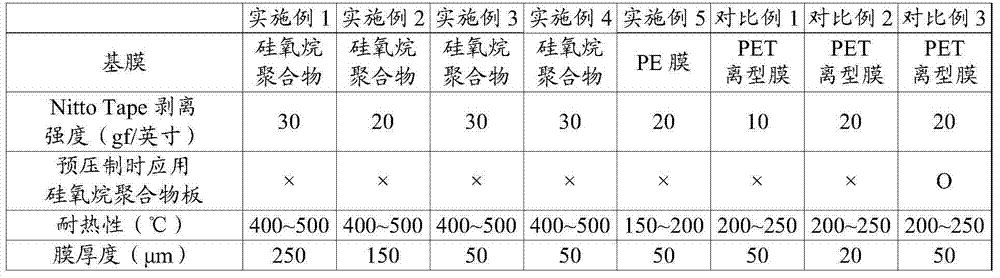

[0032] Example 1: Preparation of anisotropic conductive film

[0033]Based on the parts by weight of the solid content of the following components, 10 parts by weight of butadiene resin, 30 parts by weight of acrylate-modified urethane resin, and 20 parts by weight of acrylic copolymer were mixed, melted and dispersed with a planetary mixer , 36 parts by weight of free radical polymer material, 2 parts by weight of organic peroxide and 2 parts by weight of conductive particles. Then, the mixture was applied to a release-treated 250 μm thick silicone polymer film (storage modulus: 668 kgf / cm 2 ), and dried in a hot air circulation at 60° C. for 5 minutes to dry the solvent, thereby preparing the anisotropic conductive film of Example 1.

[0034] 1. Butadiene resin: acrylonitrile butadiene copolymer (1072CGX, Zeon Chemical Co., Ltd.), which is dissolved in toluene / methyl ethyl ketone at 25vol% (volume percentage);

[0035] 2. Acrylate-modified urethane resin: urethane acrylate...

Embodiment 2

[0040] Embodiment 2: Preparation of anisotropic conductive film

[0041] In addition to using a 150μm thick silicone polymer film (storage modulus: 659kgf / cm 2 ) except that an anisotropic conductive film was prepared in the same manner as in Example 1.

Embodiment 3

[0042] Embodiment 3: Preparation of anisotropic conductive film

[0043] In addition to using a 50μm thick silicone polymer film (storage modulus: 643kgf / cm 2 ) except that an anisotropic conductive film was prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com