Heavy hydrocarbon recovery method of propane precooling and deethanizer top reflux

A deethanizer and propane precooling technology, which is applied in the field of heavy hydrocarbon recovery in the overhead reflux of the propane precooling deethanizer, can solve the problems of large floor space, poor applicability, and difficult installation, and achieves compact equipment and increased Recovery rate, quick start and stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings and embodiments.

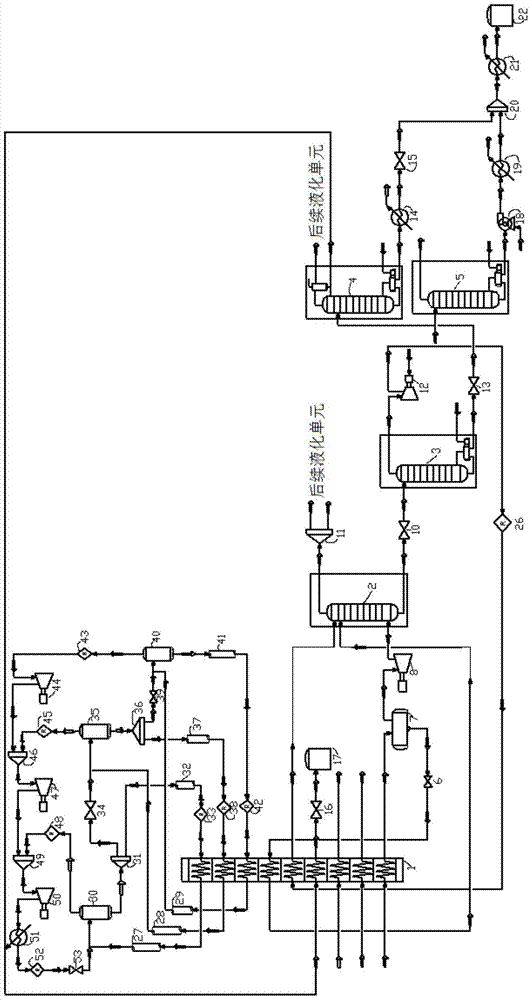

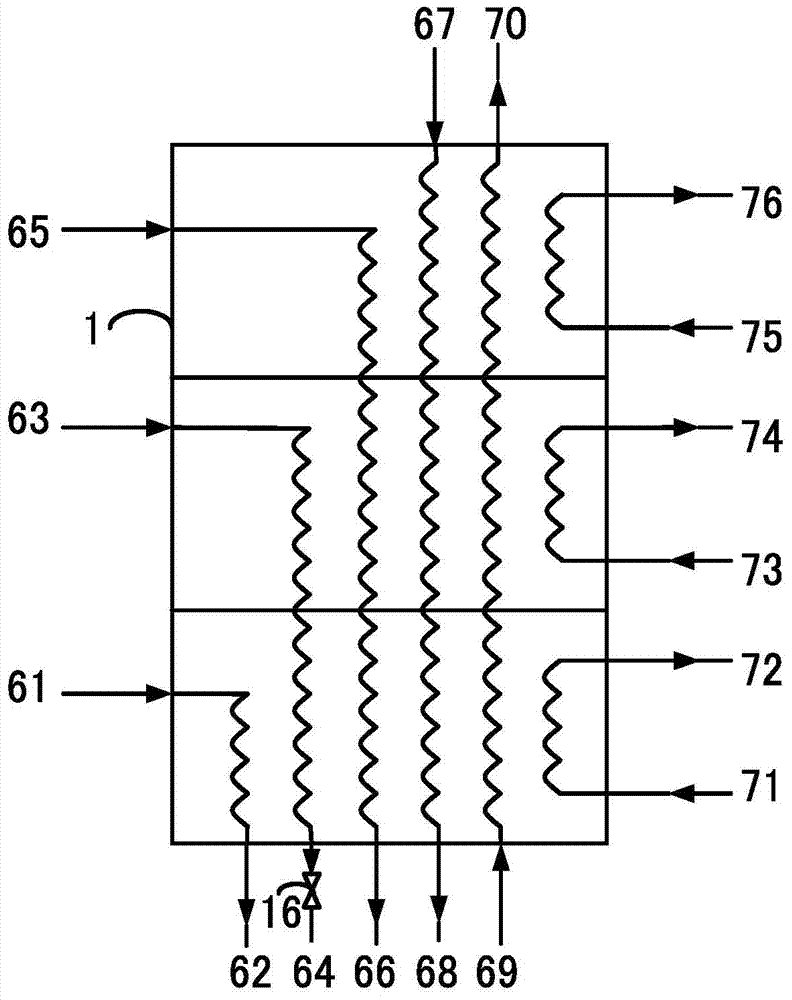

[0022] Such as figure 1 As shown, it is assumed that the pressure of natural gas after pretreatment is 7.14 MPa and the temperature is 36.0°C. The process consists of a propane pre-cooling cycle and a natural gas de-heavy hydrocarbon process.

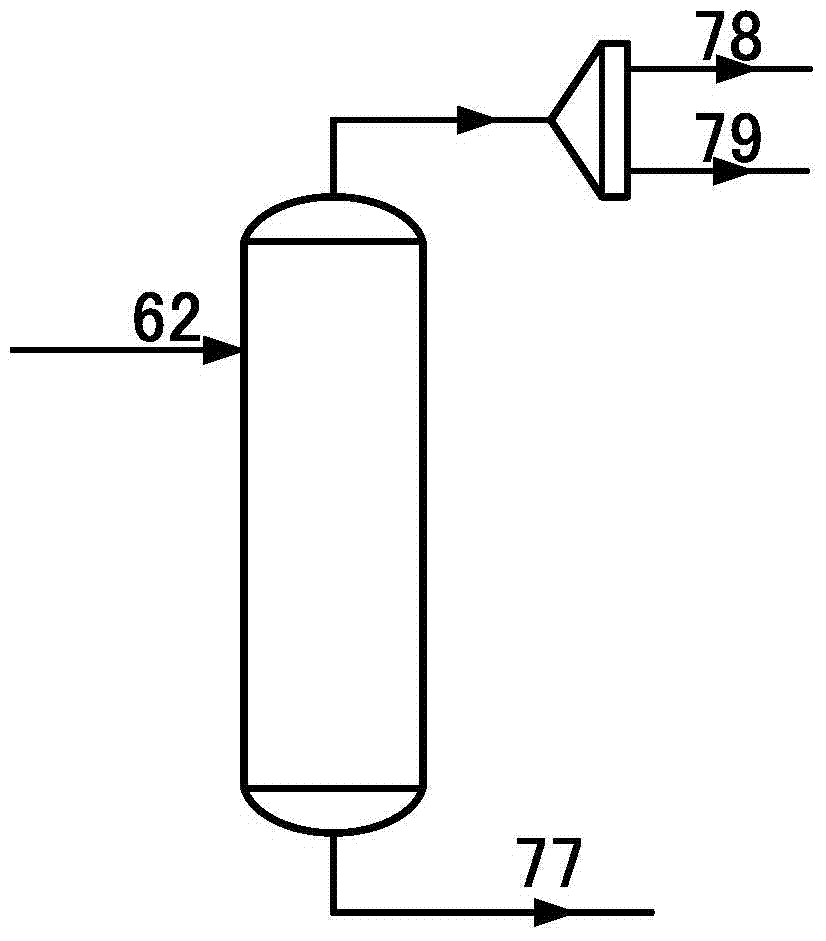

[0023] In the propane pre-cooling cold box unit, three-stage pre-cooling is used. Propane is first separated into gas-liquid two-phase by high-pressure separator 30. The gas phase is mixed with the gas compressed by propane compressor Ⅱ47 and flows into propane compressor Ⅲ50, compressed to a temperature of 52.2℃ and pressure of 1.36MPa, and then passes through the fourth water cooler When 51 is cooled to 31°C, all propane is liquefied, and the pressure is reduced to 0.55MPa through the propane throttle valve 53, and the temperature is reduced to 5°C, mixed with propane reheated from the cold box, and then flows into the high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com