Multifunctional non-toxic water-based rust-proof cutting fluid

A cutting fluid, multi-functional technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of anti-rust, stability and environmental protection, lagging green, multi-functional, high-efficiency, etc., and achieve good biological stability. , the effect of long service life, excellent corrosion inhibition and anti-rust lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

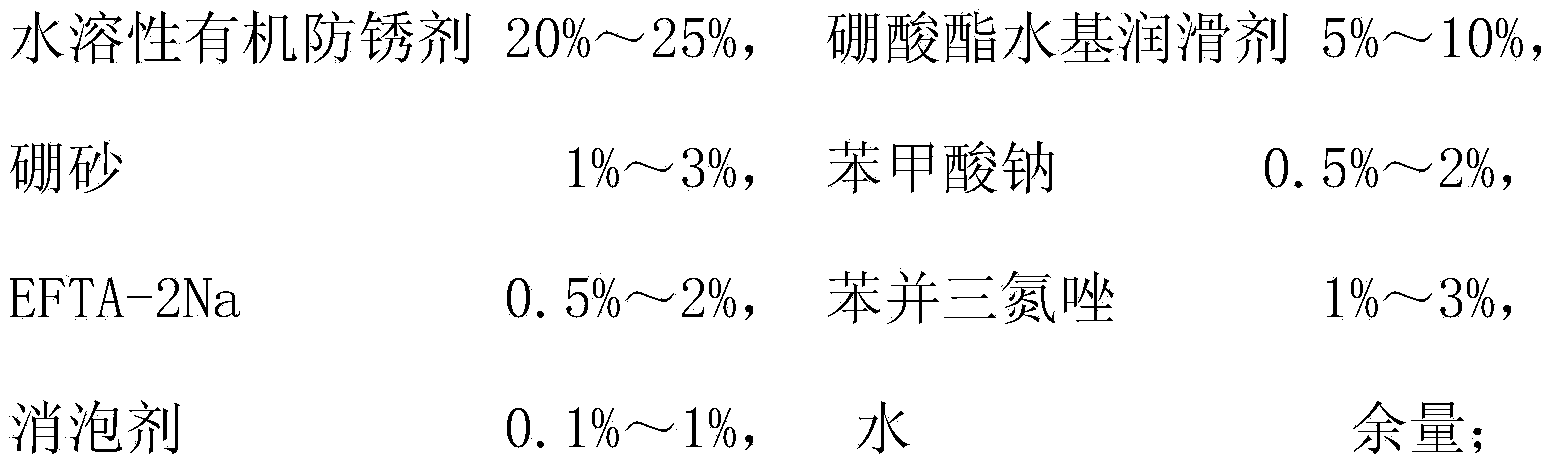

[0021] A multifunctional non-toxic water-based anti-rust cutting fluid, its composition and mass percentages are respectively:

[0022]

[0023]

[0024] The preparation method of this multifunctional nontoxic water-based antirust cutting fluid is:

[0025] (1) Preparation of water-soluble organic antirust agent: Mix sebacic acid and diethanolamine evenly at a ratio of 1:1, heat up to 65°C, stir at constant temperature for 90 minutes, and wait until the reaction solution is clear and uniform without stratification The mixed solution is cooled to room temperature, and the discharge is a water-soluble organic antirust agent;

[0026] (2) Dissolve EDTA-2Na, borax, benzoate, and benzotriazole in water in sequence;

[0027] (3) Add organic antirust agent and borate water-based lubricant to the solution prepared in step (2) in sequence, and stir evenly;

[0028] (4) When the above solution becomes clear and transparent, add defoamer and continue stirring for 1 hour to obtain...

Embodiment 2

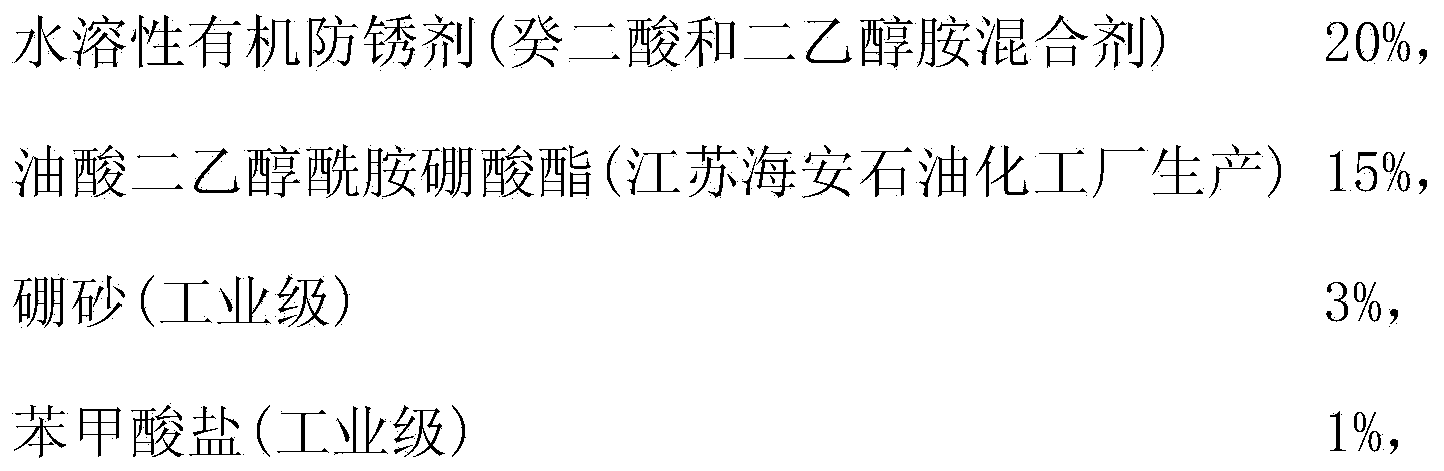

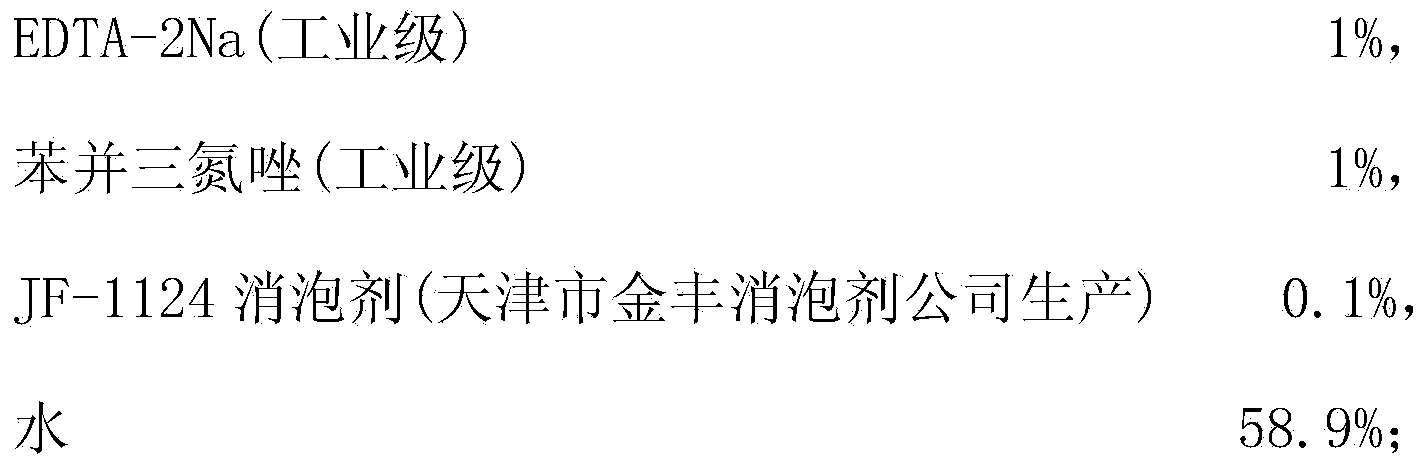

[0030] A multifunctional non-toxic water-based anti-rust cutting fluid, its composition and mass percentages are respectively:

[0031]

[0032]

[0033] The preparation method of this multifunctional nontoxic water-based antirust cutting fluid is:

[0034] (1) Preparation of water-soluble organic antirust agent: Mix organic heterocyclic polycarboxylic acid T485 and triethanolamine evenly in a ratio of 1:1.1, heat up to 75°C, stir at constant temperature for 90 minutes, and wait for the reaction liquid to be clear and free of The homogeneous mixed solution of the layer is cooled to room temperature, and the output is the water-soluble organic antirust agent;

[0035] (2) Dissolve EDTA-2Na, borax, benzoate, and benzotriazole in water in sequence;

[0036] (3) Add organic antirust agent and borate water-based lubricant to the solution prepared in step (2) in sequence, and stir evenly;

[0037] (4) When the above solution becomes clear and transparent, add defoamer and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com