P (Positive) type insert layer with cycle structure and growing method

A growth method and cyclic structure technology, applied in the field of preparation of group III nitride materials, can solve problems such as cracks, material degradation, and self-compensating deep-level hole concentration decline, so as to reduce diffusion, improve crystal quality, and improve injection efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

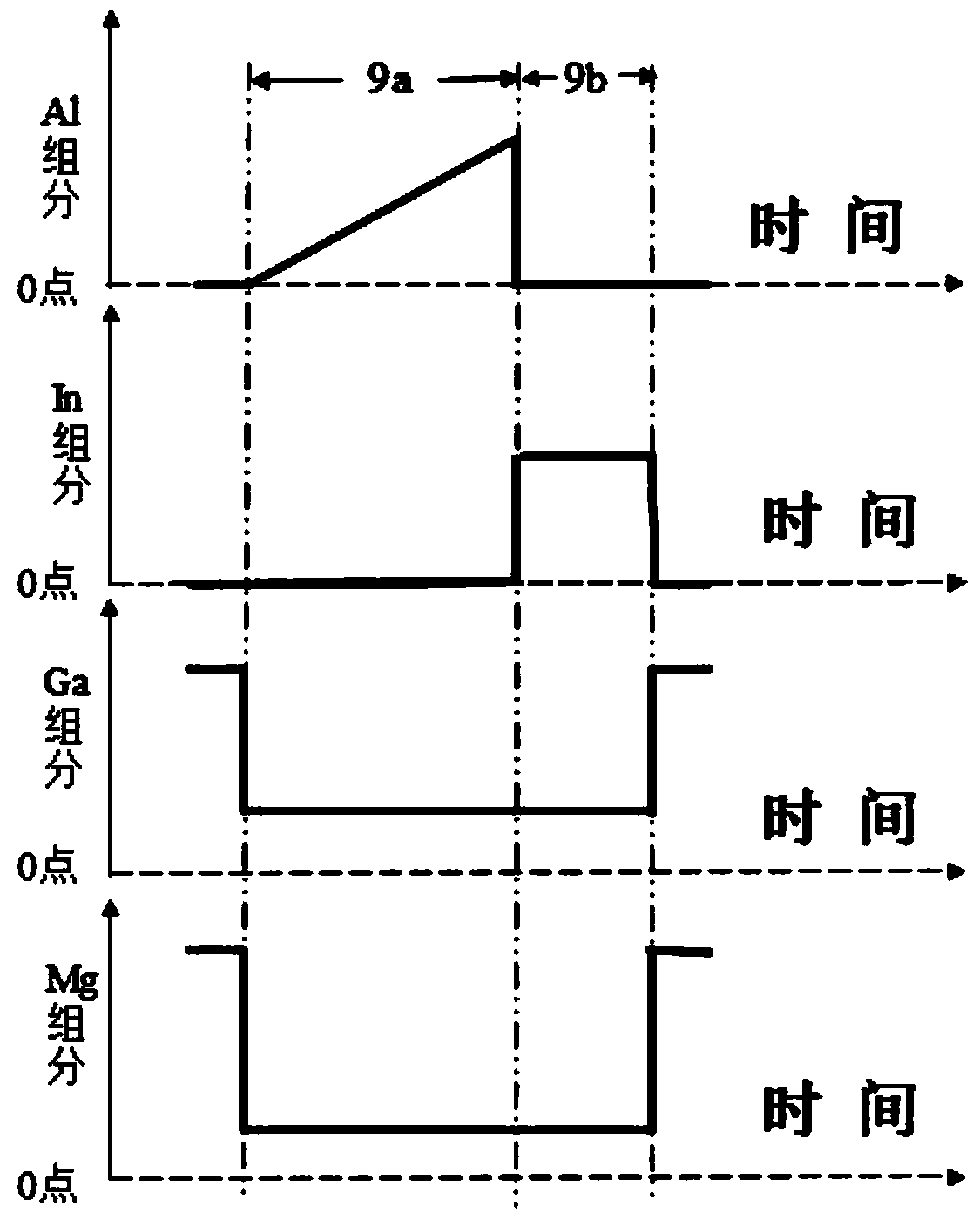

Method used

Image

Examples

Embodiment 1

[0026] A P-type insertion layer with a cyclic structure and its growth method, the order of its epitaxial structure from bottom to top is: substrate, low-temperature GaN buffer layer, GaN undoped layer, N-type GaN layer, multi-quantum well structure MQW, The growth method of the low-temperature P-type GaN layer, P-type AlGaN layer, high-temperature P-type GaN layer and P-type contact layer includes the following specific steps:

[0027] (1) Clean the sapphire substrate at a high temperature for 10 minutes in a hydrogen atmosphere at 1050°C, and then perform nitriding treatment;

[0028] (2) Cool down to 500°C, grow a low-temperature GaN buffer layer with a thickness of 25nm, the growth pressure is 500mbar, and the V / III ratio is 200;

[0029] (3) After the growth of the low-temperature GaN buffer layer is completed, stop feeding trimethylgallium (TMGa), raise the substrate temperature to 800°C, and perform in-situ thermal annealing on the low-temperature GaN buffer layer. The ...

Embodiment 2

[0041] A P-type insertion layer with a cyclic structure and its growth method, the order of its epitaxial structure from bottom to top is: substrate, low-temperature GaN buffer layer, GaN undoped layer, N-type GaN layer, multi-quantum well structure MQW, The growth method of the low-temperature P-type GaN layer, P-type AlGaN layer, high-temperature P-type GaN layer and P-type contact layer includes the following specific steps:

[0042] (1) Clean the sapphire substrate at a high temperature for 15 minutes in a hydrogen atmosphere at 1150°C, and then perform nitriding treatment;

[0043] (2) Cool down to 600°C, grow a low-temperature GaN buffer layer with a thickness of 40nm, the growth pressure is 800mbar, and the V / III ratio is 800;

[0044] (3) After the growth of the low-temperature GaN buffer layer is completed, stop feeding trimethylgallium (TMGa), raise the substrate temperature to 1050°C, and perform in-situ thermal annealing on the low-temperature GaN buffer layer. The...

Embodiment 3

[0056] A P-type insertion layer with a cyclic structure and its growth method, the order of its epitaxial structure from bottom to top is: substrate, low-temperature GaN buffer layer, GaN undoped layer, N-type GaN layer, multi-quantum well structure MQW, The growth method of the low-temperature P-type GaN layer, P-type AlGaN layer, high-temperature P-type GaN layer and P-type contact layer includes the following specific steps:

[0057] (1) Clean the sapphire substrate at a high temperature for 12 minutes in a hydrogen atmosphere at 1100°C, and then perform nitriding treatment;

[0058] (2) Cool down to 550°C, grow a low-temperature GaN buffer layer with a thickness of 30nm, the growth pressure is 600mbar, and the V / III ratio is 300;

[0059] (3) After the growth of the low-temperature GaN buffer layer is completed, stop feeding trimethylgallium (TMGa), raise the substrate temperature to 900°C, and perform in-situ thermal annealing on the low-temperature GaN buffer layer. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com