Polymer lithium ion battery diaphragm and preparation method thereof

A technology for lithium-ion batteries and polymers, applied in secondary batteries, battery components, circuits, etc., can solve the problem of enhancing the comprehensive performance of polymer lithium-ion battery diaphragms, the contradiction between ion conductivity and mechanical properties, and low-temperature conductivity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

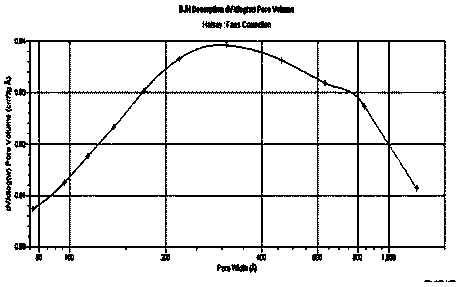

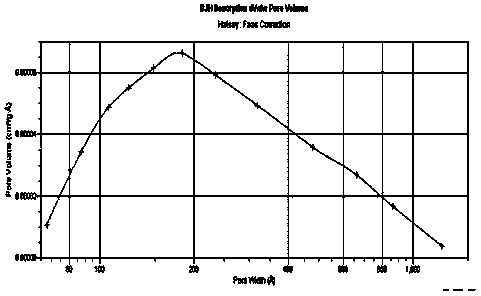

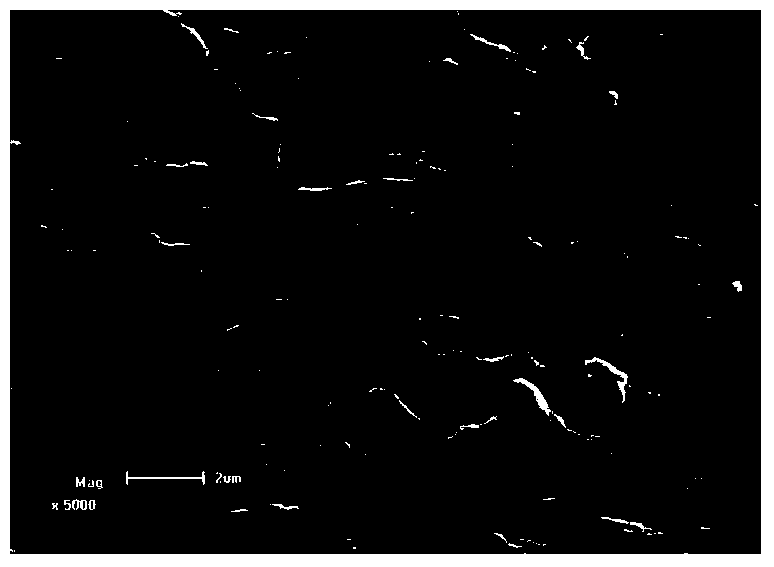

Image

Examples

Embodiment 1

[0037] Bacterial Cellulose Grafted Carbon Nanotube Composite Modified Polyvinylidene Fluoride Separator

[0038] 1) Put 10 mg of carbon nanotubes into a 250 mL round bottom flask, add 60 mL of a mixture of concentrated nitric acid and concentrated sulfuric acid (the volume ratio of concentrated nitric acid to concentrated sulfuric acid is 1:3), sonicate for 1 h, and then pack A good reflux condensation, collection and stirring device, heating and stirring and reflux at a constant temperature of 80°C. After 48 hours, it was naturally cooled to room temperature, and the obtained black solution was filtered, and the black powder on the filter paper was washed repeatedly with deionized water until the pH value was 7. Then put the carbon nanotubes on the filter paper into a vacuum oven at 80°C to dry for 24 hours, then dissolve the carbon nanotubes in 50 mL of dimethylacetamide, and disperse them ultrasonically for 1 hour to obtain a carbon nanotube solution;

[0039] 2) At the same...

Embodiment 2

[0043] Bacterial Cellulose Grafted Carbon Nanotube Composite Modified Polyacrylonitrile Separator

[0044] 1) Put 5 mg of carbon nanotubes into a 250 mL round bottom flask, add 40 mL of a mixture of concentrated nitric acid and concentrated sulfuric acid (the volume ratio of concentrated nitric acid to concentrated sulfuric acid is 1:3), and prepare according to the steps in Example 1 50mL carbon nanotube dimethylacetamide solution, and ultrasonically disperse for 1h;

[0045] 2) At the same time, take 2g of lithium chloride dried in vacuum at 150°C and add 50mL of dimethylacetamide, heat in an oil bath at 80°C to dissolve completely, then introduce 0.5g of activated bacterial cellulose, and continue heating at 80°C Stir until completely dissolved;

[0046] 3) After that, mix the above two solutions that are uniformly dissolved and dispersed, and continue heating and stirring to achieve uniform dissolution. After microwave radiation for 10 minutes, add 18g of polyacrylonitril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity at room temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com