Flow battery

A liquid flow battery and flow channel technology, applied in fuel cells, battery electrodes, regenerative fuel cells, etc., can solve the problems of strong corrosion, high price, and affecting the life of liquid flow batteries, so as to improve the service life and reduce the price , the effect of reducing cost pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation process of the positive electrode is preferably to stir and mix the positive electrode active material, positive electrode conductive agent and binder in a solvent in a certain proportion to obtain the required positive electrode slurry, then apply the positive electrode slurry on the positive electrode current collector, and dry , Tablet treatment to obtain the positive electrode.

[0047] The solvent used in the positive electrode slurry in the present invention can be selected from conventionally used solvents in the field, such as N-methylpyrrolidone (NMP), N,N-dimethylformamide (DMF), N,N- One or more of diethylformamide (DEF), dimethyl sulfoxide (DMSO), tetrahydrofuran (THF), water and alcohols. The amount of the solvent is such that the positive electrode slurry can be coated on the current collector. Generally, the amount of the solvent is such that the concentration of the positive electrode active material in the positive electrode slurry is 4...

Embodiment 1

[0066] Mix crystalline α-manganese dioxide (average particle size 500nm) with conductive agent acetylene black and binder PTFE (polytetrafluoroethylene) in a mass ratio of 60:30:10, and then coat it on stainless steel plate, dried and compacted to form the positive electrode.

[0067] A zinc plate is used as the negative electrode.

[0068] ZnSO 4 Configured as Zn for electrolyte salt 2+ Electrolyte with a concentration of 1mol / L.

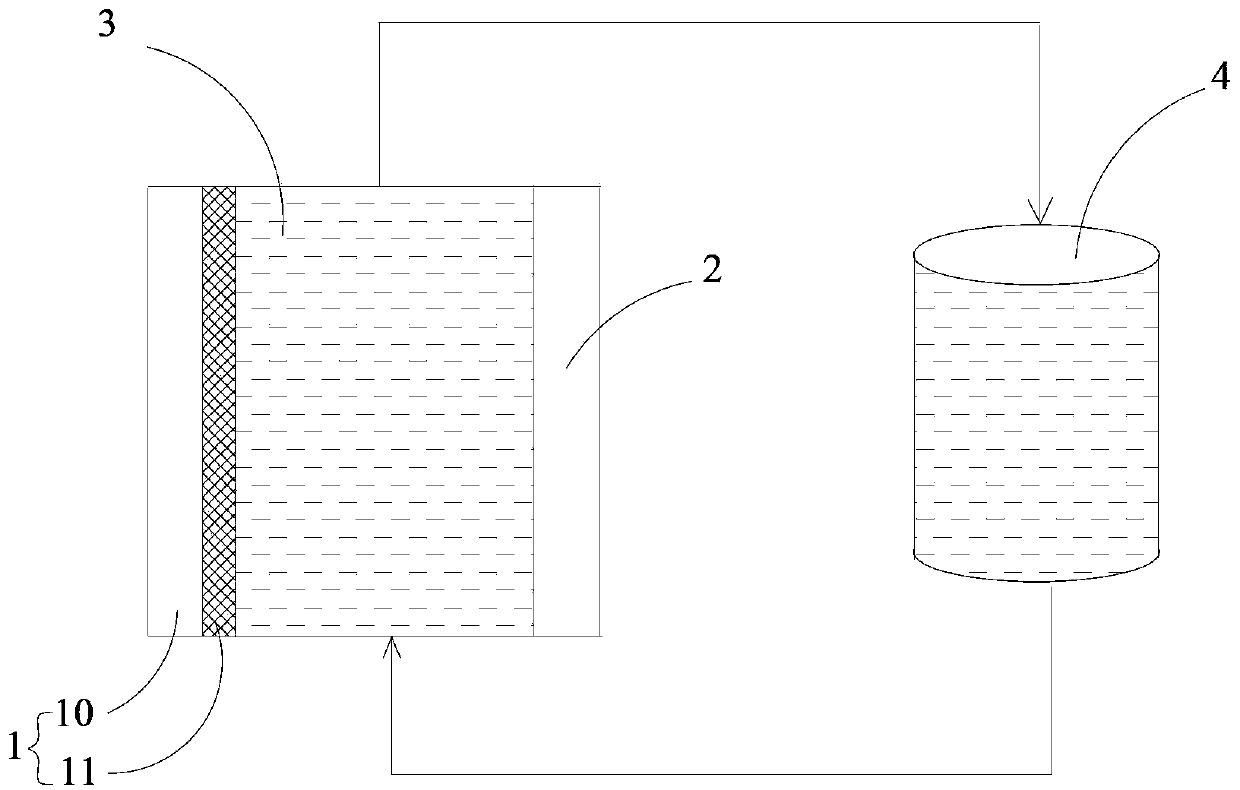

[0069] Put the positive electrode and the negative electrode into the battery case in a positive and negative manner, reserve a certain distance between the positive electrode and the negative electrode to form an electrolyte flow channel, and the electrolyte flow channel is connected to the electrolyte storage tank through the pipeline. A liquid flow pump is provided to promote the flow of electrolyte.

Embodiment 2

[0071] The difference from Example 1 is: use amorphous α-manganese dioxide instead of crystalline α-manganese dioxide, and use zinc alloy plate instead of zinc plate. Other parts are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com