Preparation and application method of a highly selective non-precious metal long-chain alkane isomerization catalyst

A long-chain alkane and non-precious metal technology, which is applied in the preparation and application of high-selectivity non-precious metal long-chain alkane isomerization catalysts, can solve the problem of lower catalyst specific surface, unsatisfactory catalyst hydrofining performance, and poor pour point depressing effect and other problems, to achieve the effect of improving activity and selectivity, unobstructed channels and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a high-selectivity non-precious metal long-chain alkane isomerization catalyst is as follows:

[0033] (1) Synthesis of SAPO-11 molecular sieve, molar ratio: Al 2 O 3 :P 2 O 5 : DPA: 0.3SiO 2 : 60H 2 O.

[0034] Mix 250g of water and 47.6g of SB powder and stir; mix 77.5g of phosphoric acid and 80g of water and add dropwise to the mixture of SB powder and water, and stir for more than 4 hours after the dropwise addition; then add 34.7g of template agent di-n-propylamine dropwise and stir for 2 hours above, and then dropwise add 23.3g of silica sol (SiO 2 Content 26%), stirred for more than 2 hours, installed in a kettle, crystallized at 200°C for 48h, then centrifuged, washed, dried at 120°C overnight, and calcined at 550°C for 24h.

[0035] (2) According to the ratio of Ni / W atomic ratio of 1:1, 44.4g of basic nickel carbonate and 76.55g of ammonium metatungstate were added to 500ml of distilled water, and then 10g of succulent powder was...

Embodiment 2

[0040] The basic situation is the same as in Example 1, except that the ratio of NiW composite oxide, molecular sieve and SB powder in the catalyst is 3:7:3, and 15g of NiW composite oxide is taken to participate in the kneading.

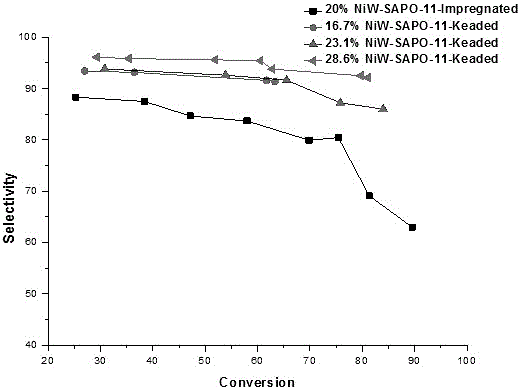

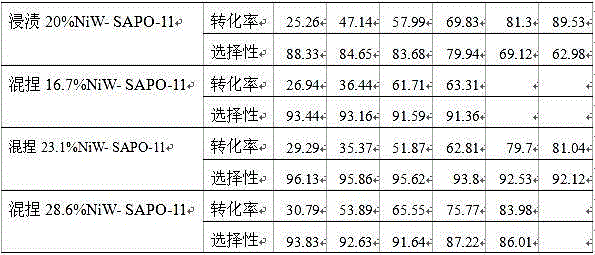

[0041] The reaction results are shown in Table 1. figure 1 . From Table 1, figure 1 It can be seen that the isomerization selectivity of the catalyst 23.1% NiW-Keaded prepared by the kneading method is higher than that of the catalyst 20% NiW-Impregnated prepared by the equal volume impregnation method.

Embodiment 3

[0043] The basic situation is the same as in Example 1, except that the ratio of NiW composite oxide, molecular sieve and SB powder in the catalyst is 4:7:3, and 20 g of NiW composite oxide is taken to participate in the kneading.

[0044] The reaction results are shown in Table 1. figure 1 . From Table 1, figure 1 It can be seen that the isomerization selectivity of the catalyst 28.6% NiW-Keaded prepared by the kneading method is high, which is much higher than that of the catalyst 20% NiW-Impregnated prepared by the equal volume impregnation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com