Copper-coated chromium composite powder and preparation method and application thereof

A technology of composite powder and copper cladding, which is applied in the direction of liquid chemical plating, coating, metal material coating process, etc., can solve the problems of short product life, poor dispersion, poor adhesion, etc., and achieve low production cost and high performance Effects of stability and purity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of the above-mentioned copper-coated chromium composite powder, comprising the following steps:

[0040] 1. Pretreatment:

[0041] The chromium powder is used as raw material, and the chromium powder is firstly pretreated; the pretreatment includes the steps of alkali washing to remove grease, pickling to remove oxide film, sensitization treatment and activation treatment.

[0042] 1.1 Alkaline cleaning and degreasing: use NaOH solution with a concentration of 2.2mol / L to 2.8mol / L to soak the raw chromium powder for 3min to 5min, and stir it at the same time during the soaking process, and constantly replenish NaOH according to the change of pH value during the soaking treatment The solution keeps the pH value in the range of 8-9 during the soaking process, and after the soaking is completed, it is washed with water and then enters the next step.

[0043] 1.2 Pickling to remove oxide film: use dilute H with a concentration of 0.5mol / L to 1.0mol / L ...

Embodiment 1

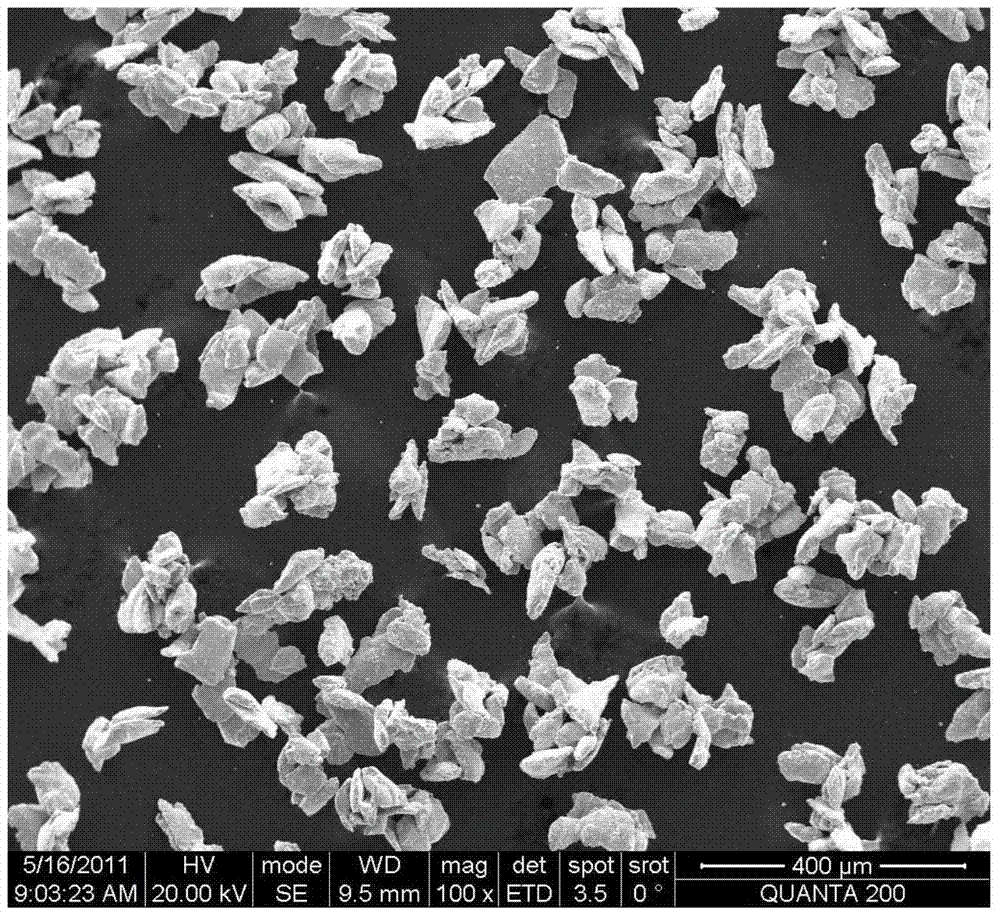

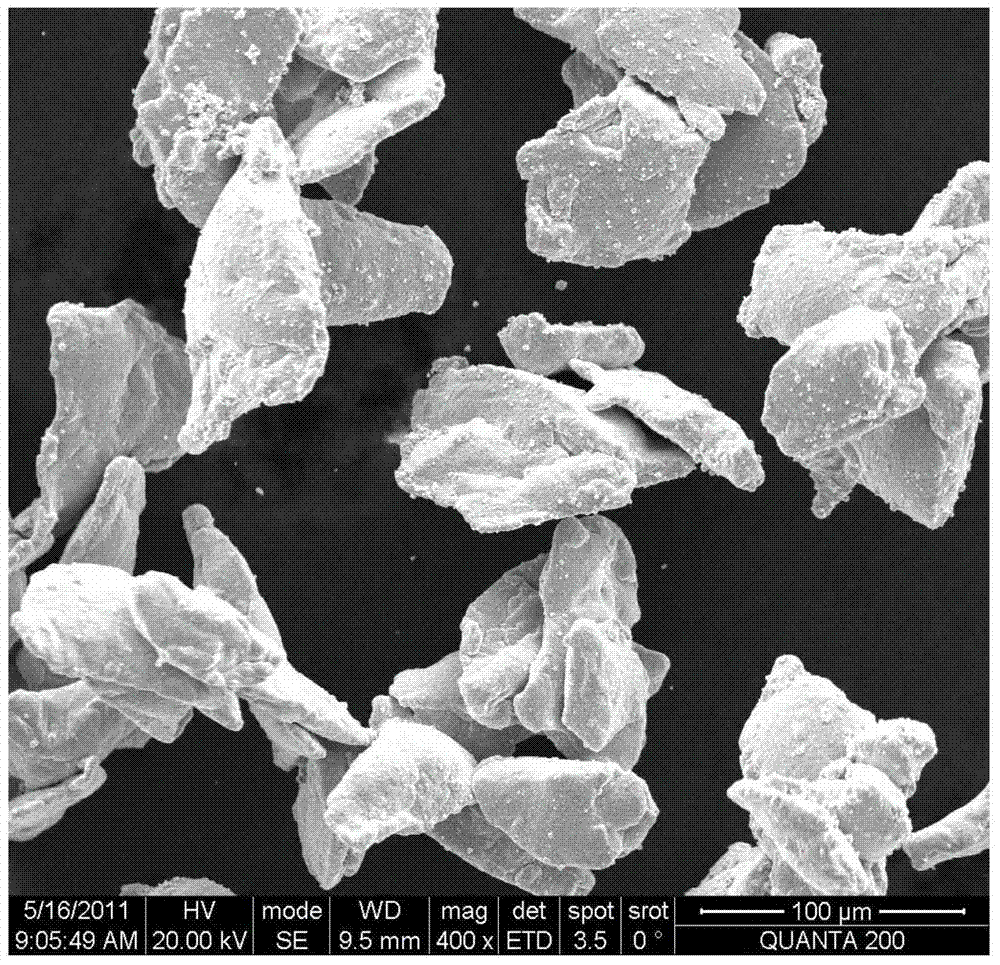

[0056] A copper-coated chromium composite powder of the present invention, comprising an inner core and an outer cladding layer, the inner core is mainly composed of irregular particles of chromium powder, and the particle size of a single irregular particle is between 30 μm and 70 μm , the outer cladding layer is mainly a continuous Cu metal layer.

[0057] A preparation method of the copper-coated chromium composite powder of the above-mentioned present embodiment, comprising the following steps:

[0058] 1. Pretreatment:

[0059] The chromium powder is used as raw material, and the chromium powder is firstly pretreated; the pretreatment includes the steps of alkali washing to remove grease, pickling to remove oxide film, sensitization treatment and activation treatment.

[0060] 1.1 Alkaline cleaning and degreasing: use NaOH solution with a concentration of 2.5mol / L to soak the raw material chromium powder for 4 minutes, and stir it at the same time during the soaking proc...

Embodiment 2

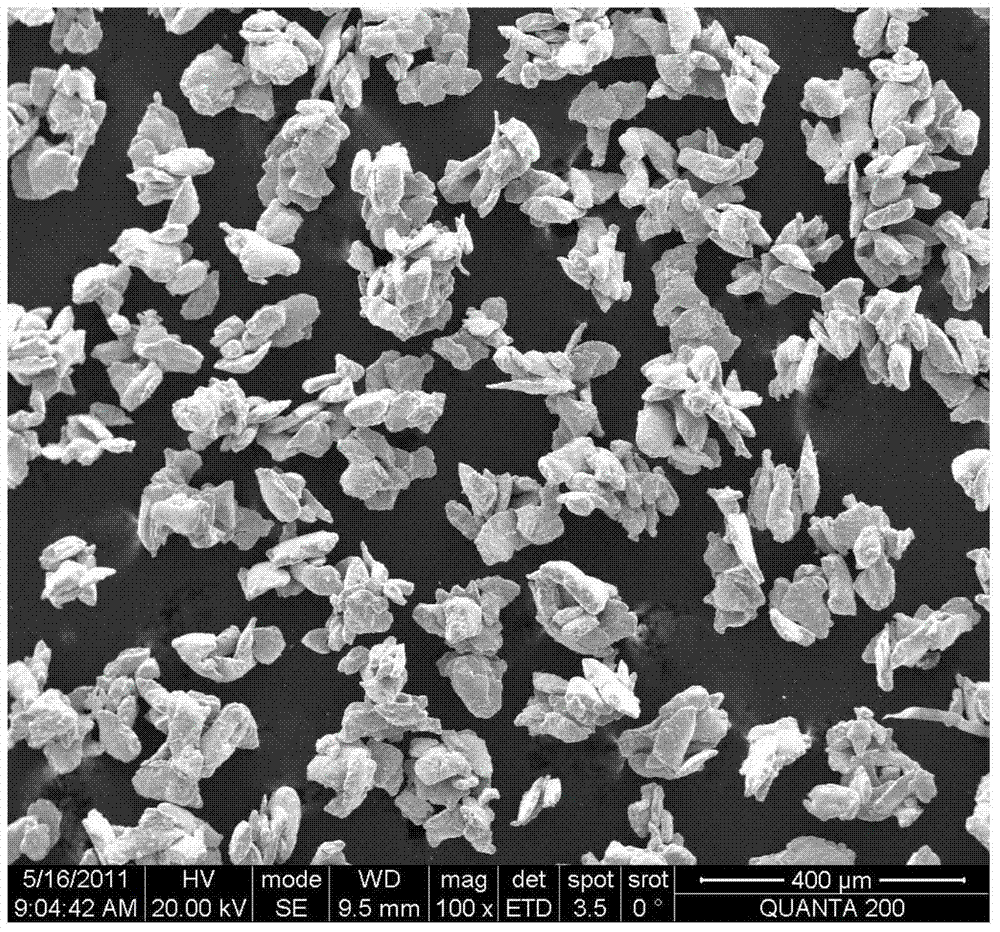

[0076] a kind of like image 3 , Figure 4 The copper-coated chromium composite powder of the present invention includes an inner core and an outer cladding layer, the inner core is mainly composed of irregular particles of chromium powder, and the particle size of a single irregular particle is between 30 μm and 70 μm , the outer cladding layer is mainly a continuous Cu metal layer.

[0077] A preparation method of the copper-coated chromium composite powder of the above-mentioned present embodiment, comprising the following steps:

[0078] 1. Pretreatment:

[0079] The chromium powder is used as raw material, and the chromium powder is firstly pretreated; the pretreatment includes the steps of alkali washing to remove grease, pickling to remove oxide film, sensitization treatment and activation treatment.

[0080]1.1 Alkaline cleaning and degreasing: Use 300mL NaOH solution with a concentration of 1.2mol / L to soak the raw material chromium powder (116g) for 5 minutes, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com