Industrial pollution-free production method of borane ester complex

A pollution-free, borane ether technology, which is applied in the field of industrial pollution-free production of borane ether complexes, can solve the problems of increased cost of wastewater treatment, agglomeration, and unsuitability for industrial production, and achieve the goal of protecting water resources and soil Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

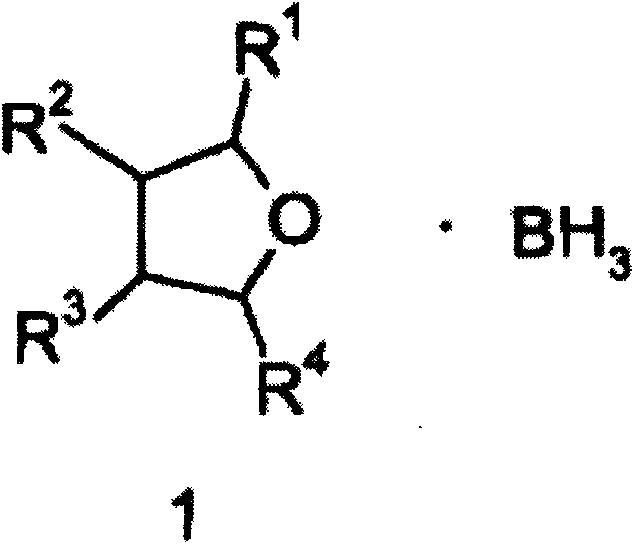

Image

Examples

Embodiment Construction

[0018] (1) dropwise adding boron trifluoride ether in the reactor;

[0019] (2) Diethylene glycol dimethyl ether is used as a solvent in the reactor, and sodium borohydride is added to react with the boron trifluoride ether added dropwise;

[0020] (3) The diborane gas produced by the reaction of step (2) enters the absorption kettle after being condensed by a condenser (-25~-30 degrees Celsius);

[0021] (4) The cooled diborane gas described in step (3) reacts with tetrahydrofuran or dimethyl sulfide in the absorption tank to form a diborane complex.

[0022] Before step (2) adds sodium borohydride, calcium oxide is added earlier. Remove water from diglyme to prevent clumping.

[0023] A cooling circulation system is arranged between the reaction kettle and the absorption kettle to maintain the temperature of the reaction kettle and the absorption kettle between 10-20 degrees Celsius. The function of the cooling circulation system is as follows:

[0024] The reaction ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com