A method for preparing organic polymer foaming material from waste oil

A technology of organic polymers and foaming materials, which is applied in the fields of comprehensive utilization of waste oil, environmental protection, and resource saving. It can solve the problems of complex polyol synthesis process, high requirements for reaction equipment, and high synthesis costs, and achieve significant profits and benefits. The effect of environmental protection and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Send 100 parts by weight of waste oil into the processor, add 5 parts by weight of sodium bicarbonate to the preprocessor, control the temperature in the preprocessor to 80°C, and continuously stir for 20 minutes; 5 parts by weight of activated clay was added to the processor, and the preconditioner was heated to 90° C., and then continuously stirred for 30 minutes to obtain pretreated waste oil.

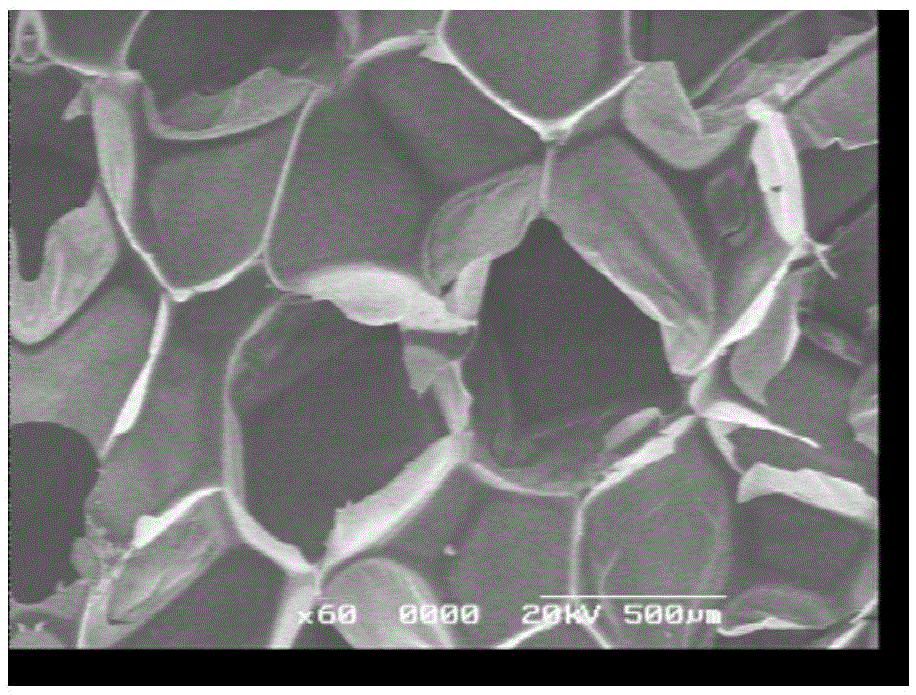

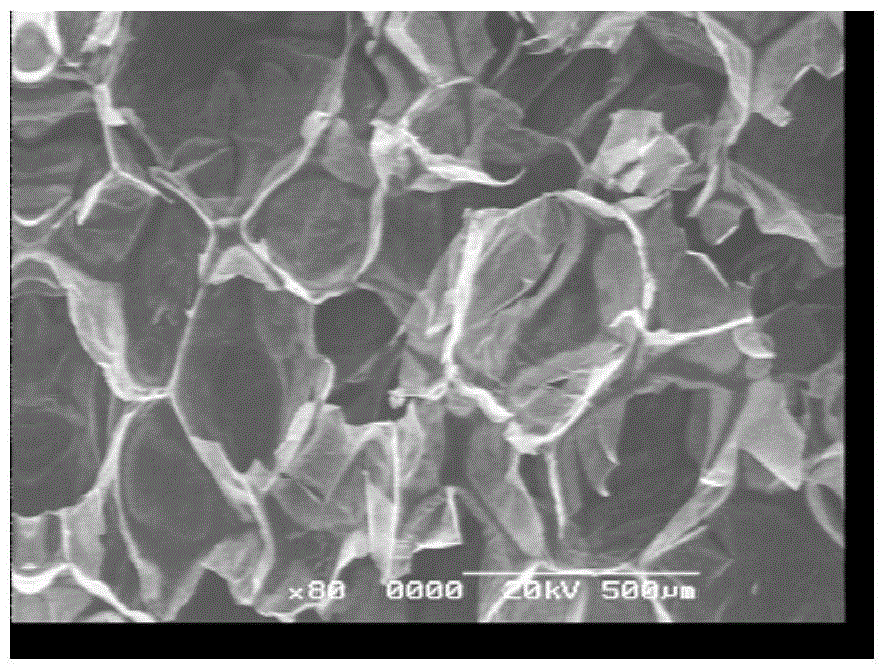

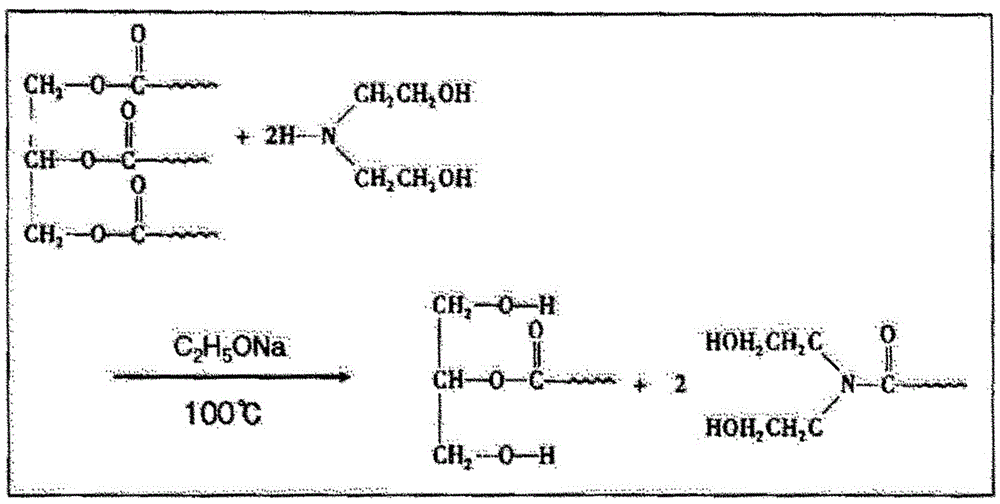

[0025] (2) Send 100 parts by weight of the pretreated waste oil prepared in the above steps into the ammonolysis reactor, add 20 parts by weight of diethanolamine and 10 parts by weight of sodium ethoxide, and control the temperature in the pretreatment device to 100°C. Continuous stirring under the atmosphere for 100 minutes to cause the waste oil to undergo ammonolysis and transesterification at medium temperature and normal pressure to obtain a mixture of polyol and diethanolamine salt. Comparing the infrared spectra of the mixture in the reactor before and after the ammo...

Embodiment 2

[0032] In Example 1, (3), the mixture of self-made polyol and diethanolamine salt replaces 25wt% of petroleum-based polyol, that is, 25 parts by weight of component A self-made polyol is added to the plastic cup, polyether polyol R180 is 75 parts by weight, and other conditions are kept unchanged. A rigid foam polyurethane material is prepared by a one-step method, which is recorded as PU25.

[0033] According to GBT6343-2009 "Determination of Apparent Density of Foam Plastic and Rubber", the apparent density of PU25 is measured to be 35.67kg / m 3 . According to the GBT8813-2008 "Determination of the Compression Performance of Rigid Foam Plastics" standard, the measured PU25 compressive strength is 157kPa and the compression modulus is 1.74GPa, which are respectively 95.73% and 95.08% of PU00. According to the GB3399.82 method, the thermal conductivity coefficient of PU25 is 0.017W / (m·K), which is 106.25% of the thermal conductivity of PU00. Therefore, the compression performance...

Embodiment 3

[0035] In Example 1 (3), the mixture of self-made polyol and diethanolamine salt replaces 50wt% of petroleum-based polyol, that is, 50 parts by weight of component A self-made polyol is added to the plastic cup, polyether polyol R180 is 50 parts by weight, and other conditions are kept unchanged. A rigid foam polyurethane material is prepared by a one-step method, which is recorded as PU50.

[0036] According to GBT6343-2009 "Determination of Apparent Density of Foam Plastic and Rubber" standard, the apparent density of PU50 measured is 32.08kg / m 3 . According to the GBT8813-2008 "Determination of the Compression Properties of Rigid Foam Plastics" standard, the measured PU50 compressive strength is 132kPa and the compression modulus is 1.4GPa, which are 88.40% and 94.00% of PU00 respectively. According to the GB3399.82 method, the thermal conductivity coefficient of PU50 is 0.019W / (m·K), which is 106.25% of the thermal conductivity of PU00. Therefore, the compression performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com