High temperature resistant nylon/PTT (polytrimethylene terephthalate)/PEIP (polyetherimide)/PBIP (polybenzimidazole) copolymer as well as preparation method and application thereof

A technology of high temperature resistance and copolymer, which is applied in the field of high temperature resistant nylon and its preparation, can solve the problems of cumbersome cost and production process, difficulty in judging the reaction end point, and difference in high temperature resistance, and achieves good material processing fluidity, simple implementation mode, The effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

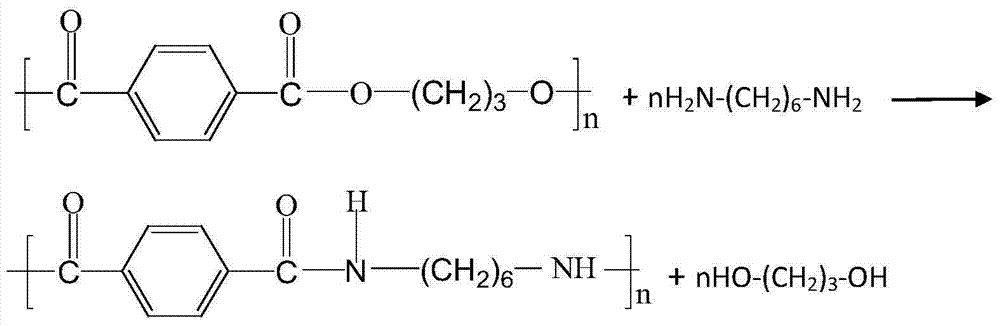

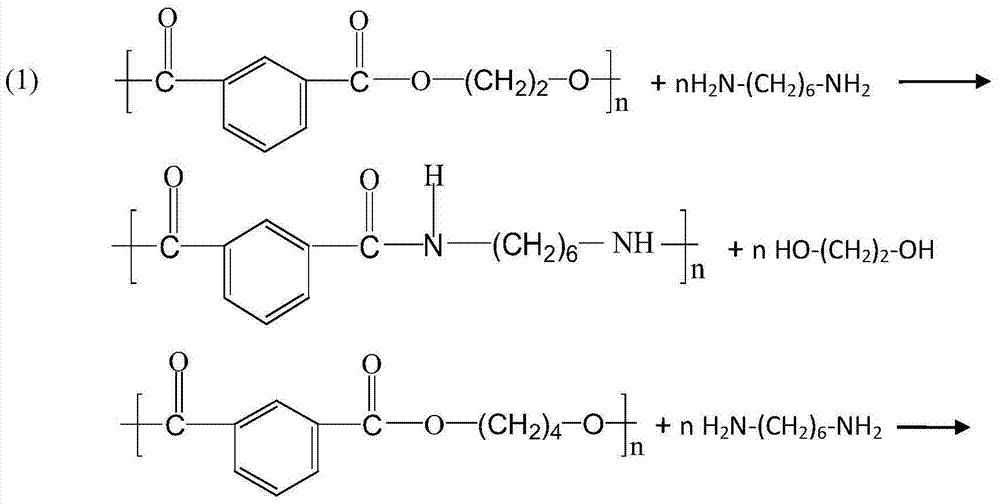

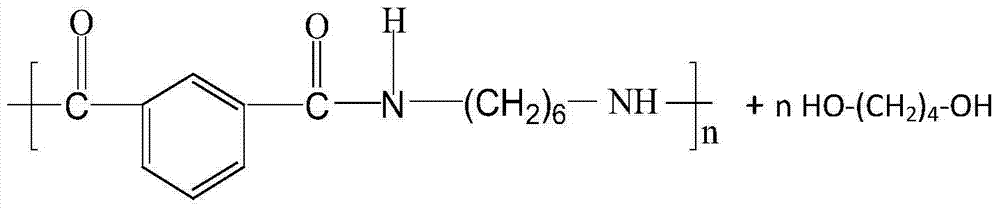

Method used

Image

Examples

Embodiment 1~3

[0046] Add PTT, PEIP, PBIP, 1,6-hexanediamine and ethanol into a 20L polymerization kettle equipped with an electric stirrer, and heat up after purging with carbon dioxide. Under stirring, the temperature rose to 220°C, the pressure rose to 2.0 MPa, and the pressure was maintained. The pressure in the kettle is controlled to be constant by removing the moisture in the reaction system, the pressure is reduced after 8 hours of pressure holding reaction, and the material is kept for 1 hour after dropping to constant temperature and normal pressure to obtain a high temperature resistant nylon / PTT / PEIP / PBIP copolymer. For specific properties, see The following table:

[0047] Table: the copolymer performance comparison table of embodiment and comparative example

[0048]

[0049] It can be seen from the table that the high-temperature-resistant nylon / PTT / PEIP / PBIP copolymer of the present invention has better heat resistance and toughness than the high-temperature-resistant nyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com