A kind of chlorinated polyethylene rubber composition

A technology of chlorinated polyethylene and rubber composition, which is applied in the direction of mechanical equipment, pipes, hoses, etc., can solve the problems of aging resistance, ozone resistance, high cost, etc., and achieve consumption saving, performance improvement, and processing safety good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

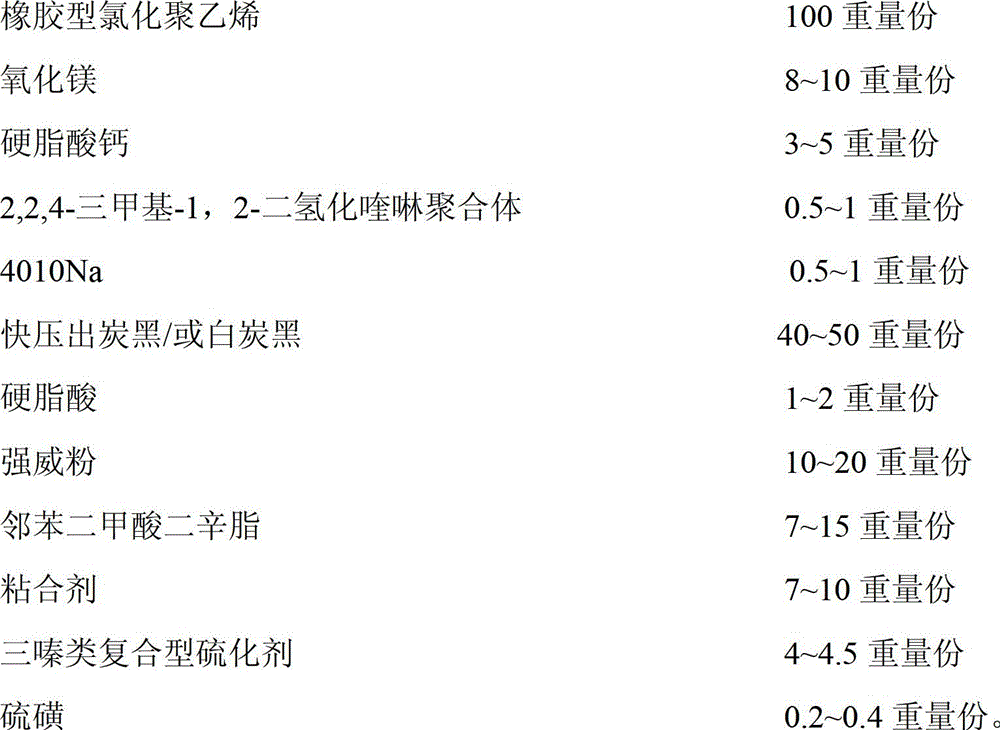

[0037] Chlorinated polyethylene rubber composition formula:

[0038]

[0039] The method for preparing the chlorinated polyethylene rubber that steel wire braided rubber hose is used is:

[0040] Firstly, weigh the chlorinated polyethylene rubber and various additives according to the formula, put the additives except vulcanizing agent and sulfur and the weighed chlorinated polyethylene rubber into the internal mixer at 60°C, and pass through The cooling water controls the rubber mixing temperature not to exceed 85°C. After 4 minutes of rubber mixing, add vulcanizing agent and sulfur and mix for about 2 minutes to discharge the material. Make 4~5 triangle bags on the open mill and then release the rubber and park it for later use. First preheat the rubber material to 55°C, extrude the hose under the condition that the temperature of the extruder body is 60°C, and the temperature of the head is 80°C. The rubber hose coated with the outer material is wrapped with water cloth...

Embodiment 2

[0049]

[0050] The method for preparing the chlorinated polyethylene rubber that steel wire braided rubber hose is used is:

[0051] Firstly, weigh the chlorinated polyethylene rubber and various additives according to the formula, put the additives except vulcanizing agent and sulfur and the weighed chlorinated polyethylene rubber into the internal mixer at 55°C, and pass through The cooling water controls the rubber mixing temperature not to exceed 85°C. After 3 minutes of rubber mixing, add vulcanizing agent and sulfur and mix for about 3 minutes to discharge the material. Make 4~5 triangle bags on the open mill and then release the rubber and park it for later use. Put the rubber material into the extruder to extrude the rubber hose. The temperature from the feed port to the fuselage is 70°C, and the temperature of the die is 75°C. The rubber hose coated with the outer material is wrapped with water cloth by a water cloth wrapping machine, and sent to a steam vulcaniza...

Embodiment 3

[0053]

[0054]

[0055] The method for preparing the chlorinated polyethylene rubber that steel wire braided rubber hose is used is:

[0056] First, weigh the chlorinated polyethylene rubber and various additives according to the formula, put the additives except vulcanizing agent and sulfur and the weighed chlorinated polyethylene rubber into the internal mixer at 70°C, and pass through The cooling water controls the rubber mixing temperature not to exceed 85°C. After 4 minutes of rubber mixing, add vulcanizing agent and sulfur and mix for about 2 minutes to discharge the material. Make 4~5 triangle bags on the open mill and then release the rubber and park it for later use. First preheat the rubber material to 60°C, extrude the hose under the condition that the temperature of the body of the extruder is 60°C, and the temperature of the head is 90°C. The rubber hose coated with the outer material is wrapped with water cloth by a water cloth wrapping machine, and sent t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com