Zen toxin-degrading enzyme oxa of Acinetobacter and its coding gene and application

A technology of encoding genes and degrading enzymes, applied in the direction of applications, enzymes, enzymes, etc., to achieve the effect of strong degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

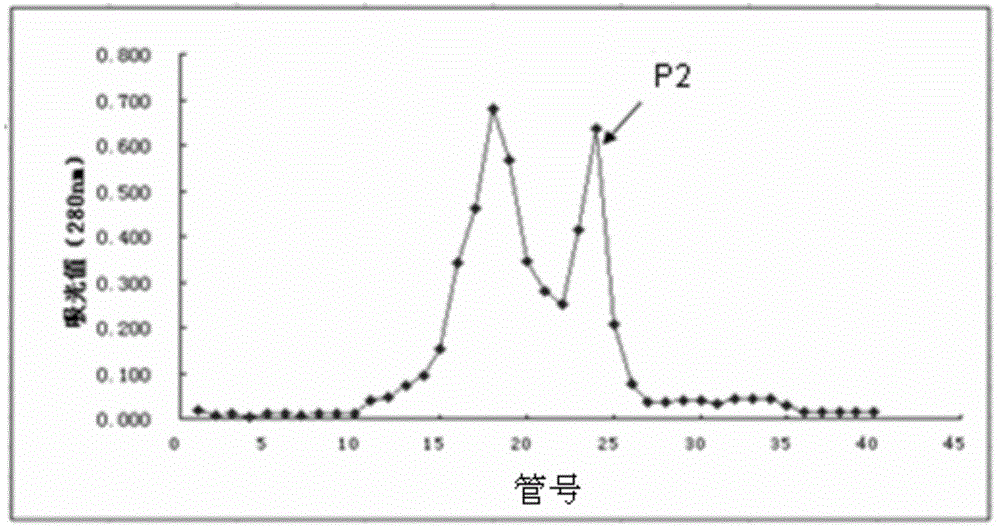

[0038] A kind of preparation of the non-peroxidase enzyme component of acinetobacter degrading ZEN comprises the following steps:

[0039] 1. Culture: inoculate with 2% (v / v) Acinetobacter sp.SM04 bacterial suspension (OD 600 =0.8) culture (M2 medium) was cultured in an air-bath shaker at 30°C (180r / min) for 36h to the end of logarithmic growth, and the liquid culture was centrifuged for 12min (9000×g, 5°C). The supernatant was filtered with a 0.22 μm filter membrane, and the filtrate was concentrated 9 times at 50°C using a vacuum rotary evaporator to become a crude enzyme solution;

[0040] The formulation of the medium used is as follows:

[0041] M2 medium: 15g sodium acetate, 2.75g NH 4 NO 3 , 1.35g K 2 HPO 4 ·3H 2 O, 1.25g KCl, 0.5g MgSO 4 ·7H 2 O, add 10mL trace element stock solution, add distilled water to make up to 1000mL, adjust the pH to 7.3 after mixing;

[0042] Formula of trace element stock solution: 2g / L FeSO 4 ·7H 2 O, 0.5g / L MnSO 4 4H 2 O, 0.4g...

Embodiment 2

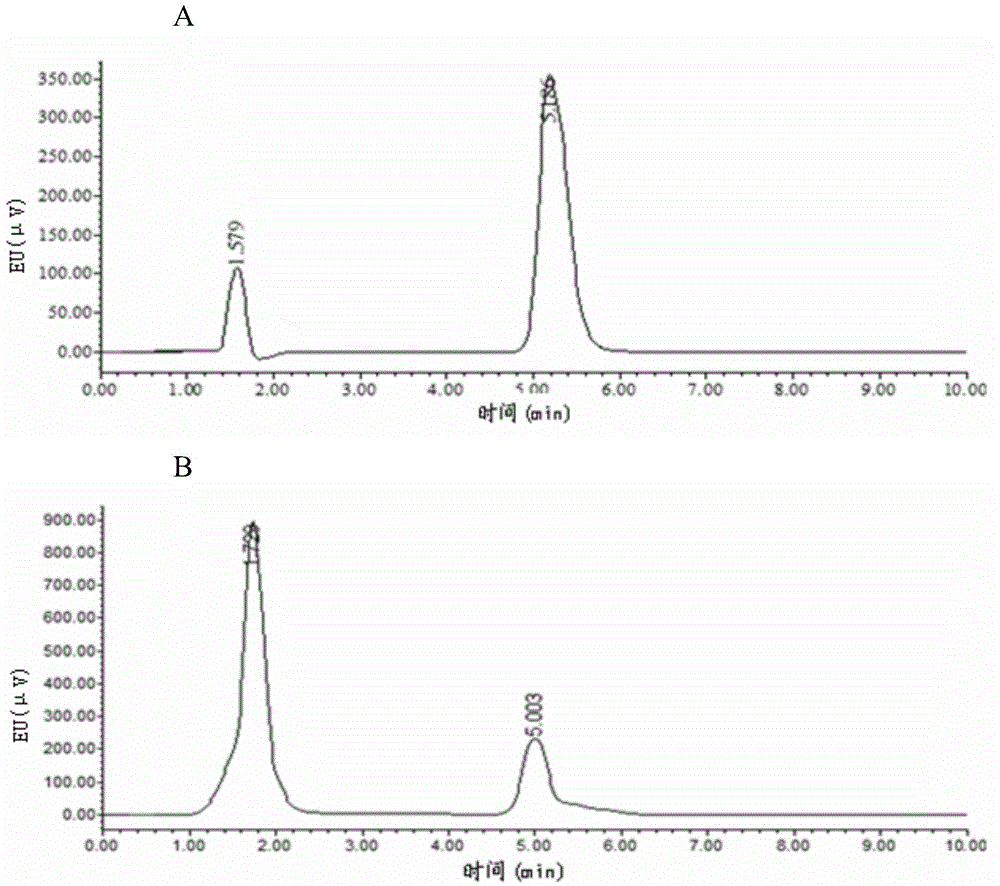

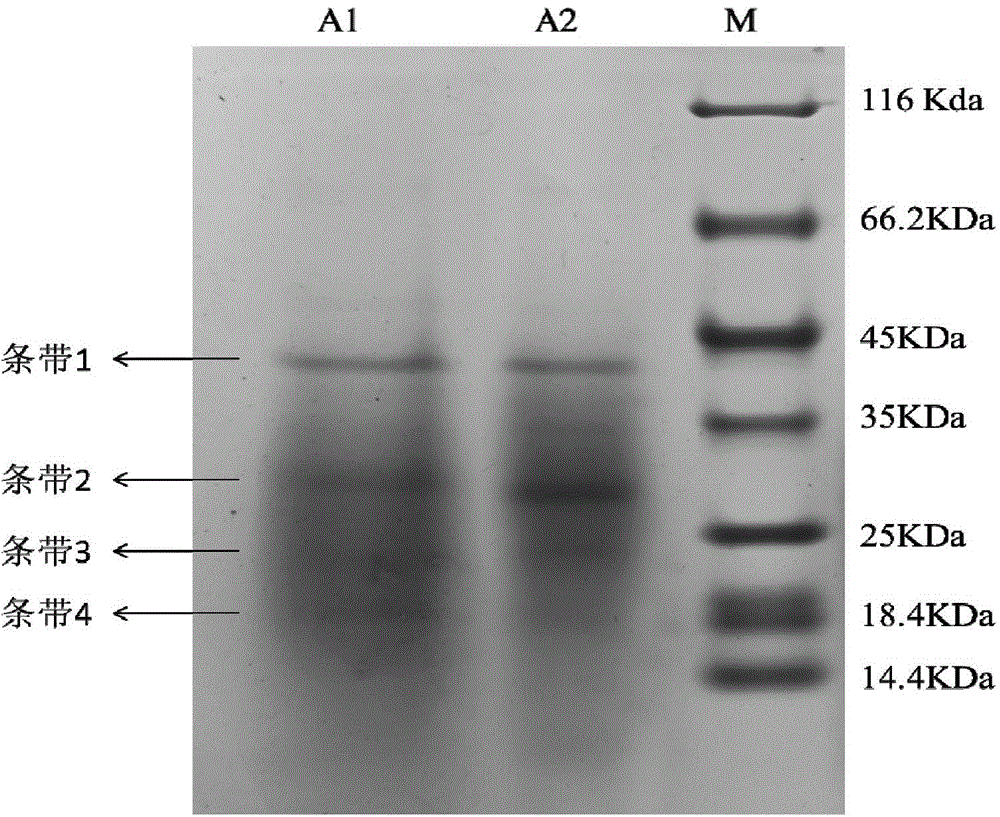

[0051] The analysis and identification of the ZEN toxin degrading enzyme Oxa enzyme component comprises the following steps:

[0052]1. The ZEN toxin-degrading enzyme Oxa enzyme component finally obtained in Example 1 is analyzed by 12.5% (w / v) SDS-PAGE gel electrophoresis, and after Coomassie brilliant blue staining, the result is as follows image 3 .

[0053] SDS-PAGE protein electrophoresis solution: 10% (w / v) sodium dodecylbenzenesulfonate (SDS) solution; 1% (v / v) tetramethylethylenediamine (TEMED); 10% (w / v) ) ammonium persulfate (AP);

[0054] Sample solution: 2% (w / v) SDS, 5% (v / v) β-mercaptoethanol, 10% (v / v) glycerol, 0.02% (w / v) bromophenol blue, 10mM pH8.0Tris- HCl buffer;

[0055] Gel storage solution: 30% separating gel storage solution, 10% concentrating gel storage solution;

[0056] Gel formulation: 4.9mL monomer, 5.0mL buffer, 3.5mL distilled water, 2.0mL glycerol, 50μL 10% (w / v) AP, 10μL TEMED.

[0057] Stacking gel formula: 1.62mL monomer, 3.10mL buf...

Embodiment 3

[0068] Cloning of ZEN Toxin Degrading Enzyme Oxa Gene

[0069] (1) Extract the total DNA of Acinetobacter sp.SM04

[0070] Take 1 mL of Acinetobacter sp.SM04 cells cultured to the logarithmic phase, first add 567 μL of TE buffer, then add 30 μL of 10% SDS and 15 μL of proteinase K, mix well, and incubate at 37 °C for 1 h. Add 100 μL 5mol / L NaCl, mix well, then add 80 μL CTAB (cetyltrimethylammonium bromide) / NaCl solution, mix well, and then incubate at 65°C for 10 minutes.

[0071] Add an equal volume of phenol / chloroform / isoamyl alcohol and mix well, centrifuge for 4-5 minutes, transfer the supernatant to a new tube, add 0.6-0.8 times the volume of isopropanol, and gently mix to precipitate DNA. After washing with 1 mL of 70% ethanol by volume, centrifuge, discard the ethanol, and air dry. Suspend the DNA in sterile water or 50 μL TE buffer to dissolve, and store at -20°C for later use.

[0072] (2) Acquisition of gene encoding ZEN toxin degrading enzyme Oxa

[0073] 1. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com