Method for preparing nano-diamond on sodium chloride substrate

A nano-diamond and substrate technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as preparing nanodiamonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Use sodium chloride as the substrate, use PECVD equipment, heat up to 800°C in a hydrogen atmosphere, and the heating rate is 20°C / min. When this temperature is reached, methane gas is introduced to make the ratio of methane and hydrogen to 1: 4. The total pressure is controlled at 1200Pa;

[0021] 2) In the PECVD equipment, after completing step 1), turn on the RF power supply, control the RF power at 260W, and the deposition time is 30-40min;

[0022] 3) After the reaction is over, continue to pass hydrogen to room temperature;

[0023] According to the exemplifying method of the above-mentioned invention, a nano-diamond material can be prepared, and this material has the following characteristics:

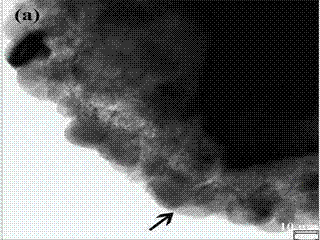

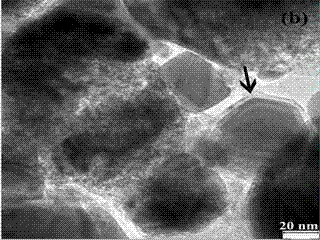

[0024] 1) Perform transmission electron microscope (TEM) characterization on the samples obtained by the method used in the above invention. It shows that the particle size of diamond is between 15-20nm.

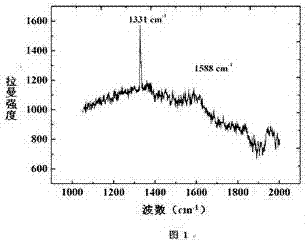

[0025] 2) Raman analysis is performed on the samples obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com