A radiator based on Stirling engine

A Stirling engine and radiator technology, applied in the direction of machines/engines, hot gas variable displacement engine devices, electrochemical generators, etc., can solve the problems that the device is only applicable and the thermal kinetic energy radiator is not applicable, and is beneficial to Recycling, saving output power, and maintaining temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

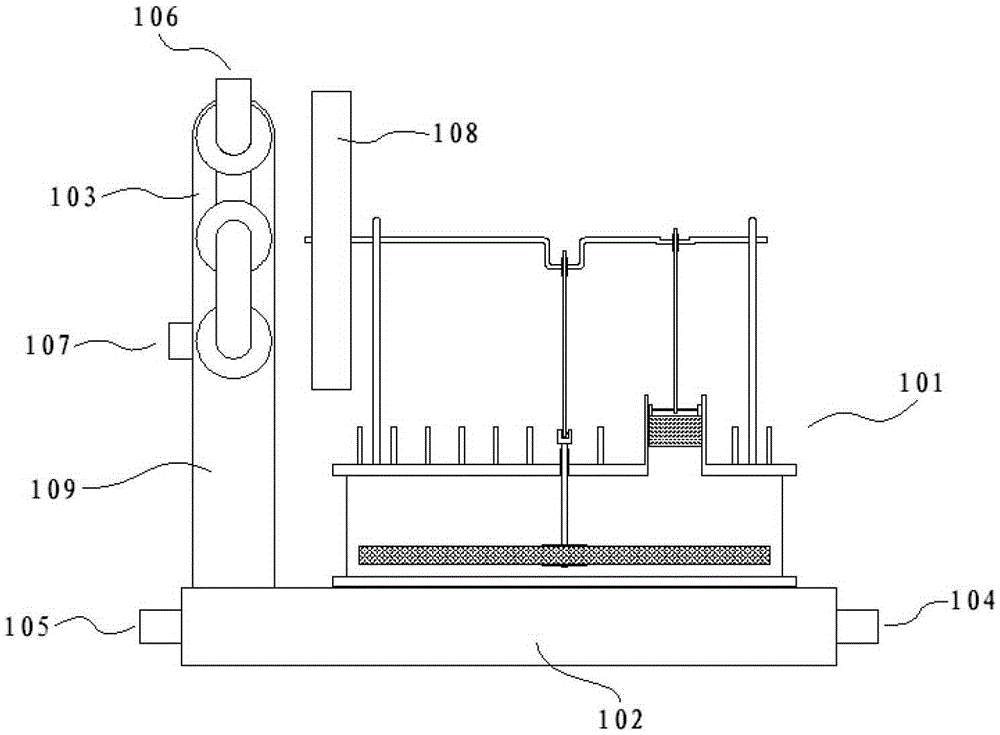

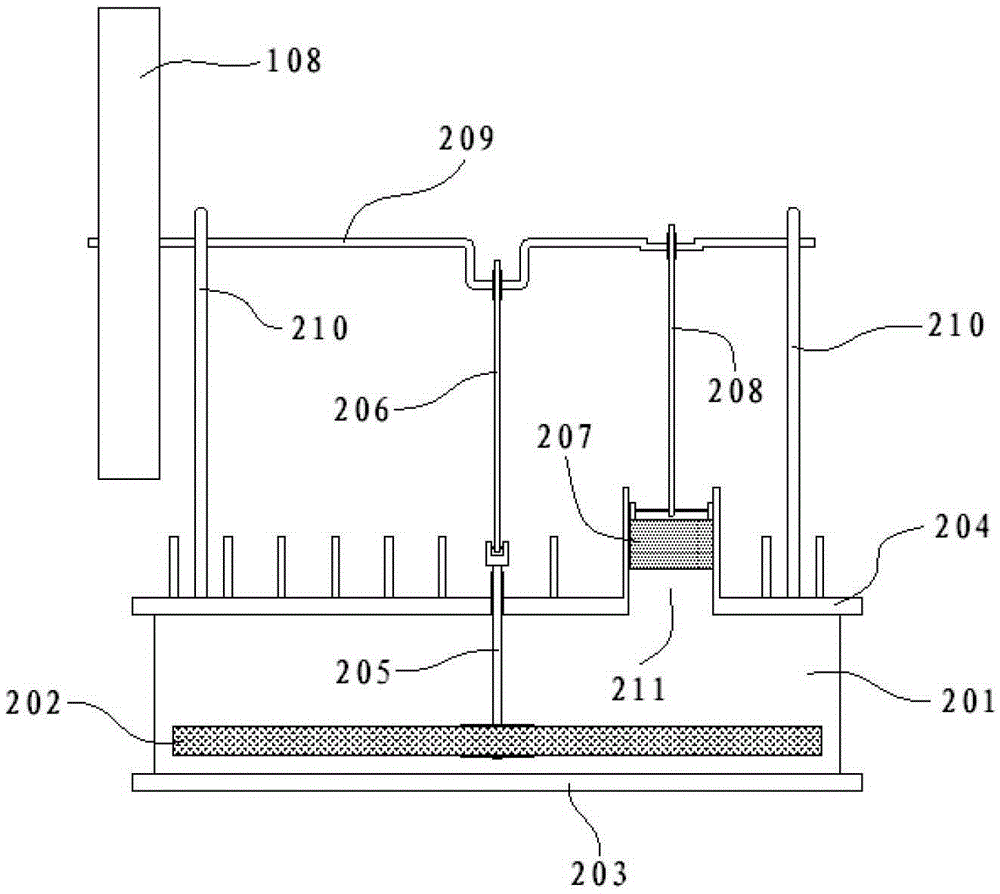

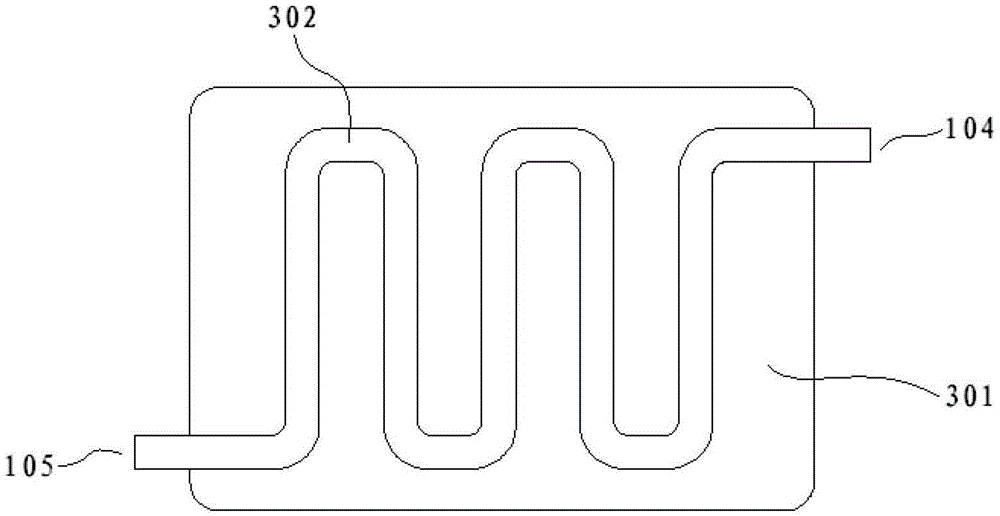

Embodiment 1

[0028] In a 100W DMFC system, the operating temperature of the fuel cell stack is about 72°C. The anode material of the fuel cell stack is methanol solution, and the temperature of the methanol solution is approximately equal to the temperature of the fuel cell stack during normal operation. Driven by the circulation pump, the methanol solution flows out from the anode outlet of the stack and enters the heat exchanger 102 through the heat exchanger material inlet 104 . When the methanol solution flows through the material channel 302 of the heat exchanger, heat is transferred to the heat conducting plate 301 , and then flows into the next component through the material outlet 105 of the heat exchanger. The heat conducting plate 301 transfers heat to the Stirling engine 101 above. Stirling engine 101 drives flywheel 108 to rotate. Driven by the air pump, water vapor, carbon dioxide, unreacted waste gas, etc. from the cathode outlet of the fuel cell stack enter the cathode mat...

Embodiment 2

[0030]In a hydrogen-oxygen fuel cell system with a power of 25kW cooling water circulation, the anode material is hydrogen, the cathode material is air, the working temperature of the fuel cell stack is about 72°C, and the cooling water circulation is used to maintain heat balance. The cooling water enters the heat exchanger 102 from the fuel cell stack cooling water outlet through the heat exchanger material inlet 104 driven by the cooling water pump. When the cooling water flows through the material channel 302 of the heat exchanger, heat is transferred to the heat conducting plate 301 , and then flows into the next component through the material outlet 105 of the heat exchanger. The heat conducting plate 301 transfers heat to the Stirling engine 101 above. Stirling engine 101 drives flywheel 108 to rotate. Driven by the air pump, cathode materials such as water vapor and unreacted waste gas from the cathode outlet of the fuel cell stack enter the cathode material radiator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com