A non-contact measurement system of nozzle arc temperature based on optical fiber transmission

A technology of non-contact measurement and arc temperature, which is applied in the field of arc temperature optical measurement system, can solve the problems that the spectral diagnosis method cannot be used, and achieve the effects of being free from electromagnetic interference, high in technical content, and avoiding the saturation of optical signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

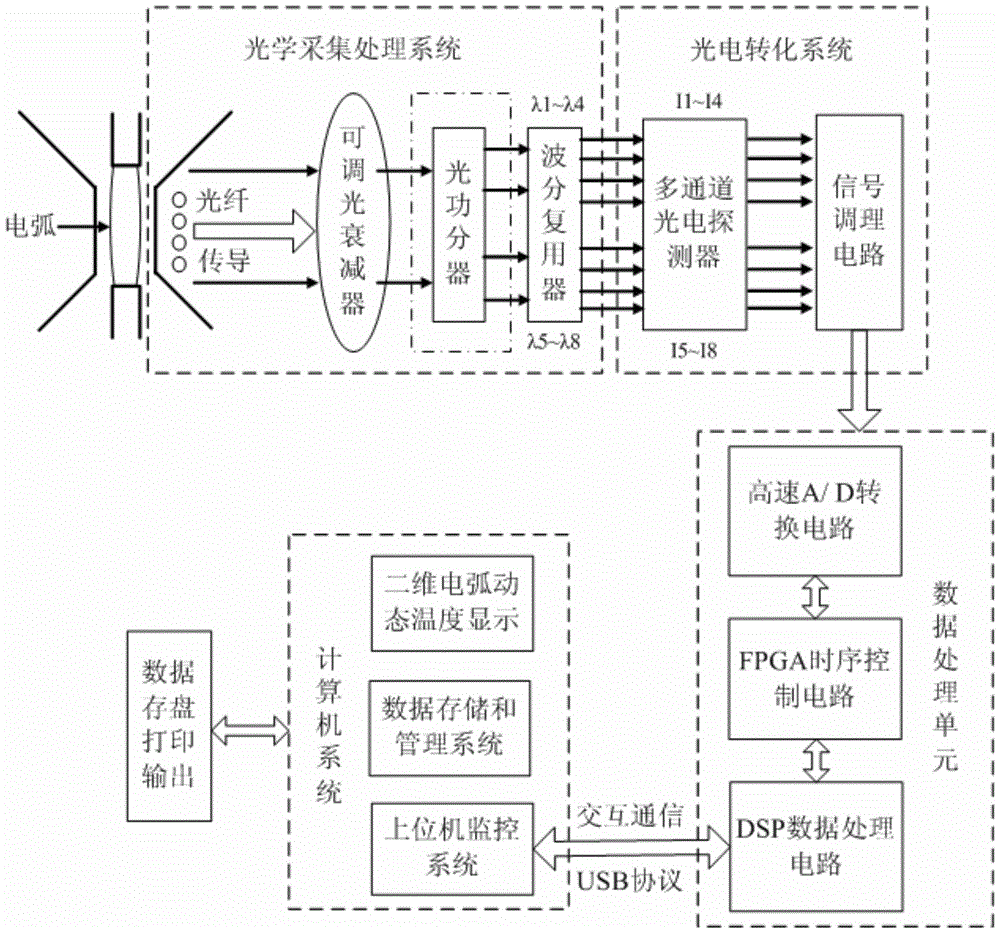

[0039] The workflow of the whole measurement system is as follows: figure 1 As shown, including optical acquisition and processing system (fiber detection array, adaptive adjustable attenuator, multiple wavelength division multiplexer), photoelectric conversion system (multi-channel photon detector, signal conditioning circuit), data processing unit and computer system . The optical acquisition and processing system realizes optical power adjustment and monochromatic characteristic light splitting selection, and the photoelectric conversion system converts multiple optical signals into electrical signals, and performs filtering and signal processing. The data processing unit (high-speed A / D conversion circuit, FPGA and DSP joint structure) realizes the calculation of the arc temperature by using the optical radiation intensity of the characteristic wavelength, and communicates to the computer system through USB data, and realizes the result by the upper computer software of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com