Screw capable of absorbing compound interface and manufacturing method of screw

A technology of interface screw and screw, applied in internal bone synthesis, medical science, internal fixator, etc., can solve the problems of PLLA without osteoinductive function, unstable ligament fixation, poor osteogenic effect, etc., and achieve good osteoinductivity , good biocompatibility, and enhance the effect of promoting calcification of fibrocartilage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

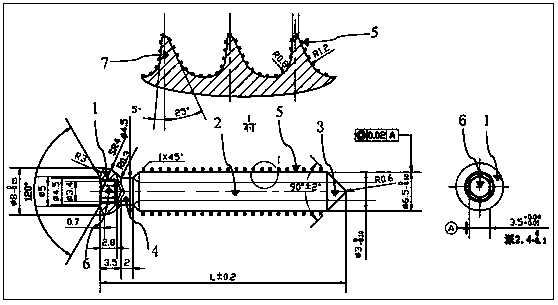

[0034] see figure 1 , figure 2 , a screw with an absorbable composite interface according to the present invention is composed of a screw cap 1, a screw rod 2, a screw head 3, a connector 4, and a gene thin layer 5, and the screw cap 1 and the screw rod 2 are fixedly connected by a connector 4, The screw head 3 is arranged on the head end of the screw rod 2, the upper end of the screw cap 1 is provided with a groove 6 corresponding to the installation screw torque wrench, the outer edge of the screw rod 2 is provided with a self-tapping thread 7, and the gene thin layer 5 covers the screw thread surface.

Embodiment 2

[0035] Example 2 Fabrication and Characterization of Absorbable Composite Interface Screws Assembled by COMP Gene TLC

[0036] (1) PLLA in 0.2g ml -1 The concentration is dissolved in 1,4-epoxyhexacycline solution, and then 20HAP powder is added, and the mass ratio of the above two is 2:8 for mixing;

[0037] (2) Add NaCl particles with a diameter of 280-450um into a screw model with a diameter of 4mm to fill it tightly, place it in an environment saturated with water vapor at 70°C for 1.5h, and after cooling at room temperature, put the PLLA / 20HAP obtained in step (1) The mixture is slowly added therein, and the air bubbles are removed by vacuuming under the condition of 0.07-0.08Mpa. Pre-freeze in -40°C refrigerator for 3 hours and then freeze for 24 hours;

[0038] (3) Soak the sample prepared in step (2) in distilled water for 24 hours, remove NaCl, and freeze-dry again to obtain PLLA / 20HAP absorbable composite interface screws;

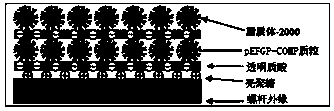

[0039] (4) Soak the PLLA / 20HAP absorb...

Embodiment 3

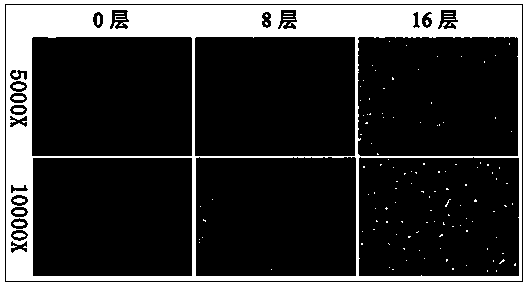

[0052] Example 3 Exploration of the transfection efficiency of mesenchymal stem cells with different layers of gene thin layer.

[0053] Using the manufacturing method of Example 1, absorbable composite interface screws assembled with 0, 4, 8 and 12 layers of COMP gene thin layers were manufactured respectively. SD rat mesenchymal stem cells were cultured by density gradient centrifugation and time-difference adherence, and the mesenchymal stem cells were inoculated into a six-well plate and co-cultured with interface screws of different layers. The cell inoculation density was 40,000 cells / cm 2 . Cultured in DMEM medium plus 10% fetal bovine serum. After 48 hours, the GFP fluorescence in each group with different layers was observed with a fluorescence microscope to detect the cell transfection, and the GFP fluorescence intensity in each group was calculated by IPP6.0 software.

[0054] see Figure 6 , 7 , the results showed that the fluorescence intensity of GFP increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com