Boron-strontium ion adsorbent, preparation method and application of adsorbent

A technology of adsorbent and strontium ion, applied in the field of selective separation of metal ions, can solve the problems of high cost and large environmental impact, and achieve the effect of simple and fast preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

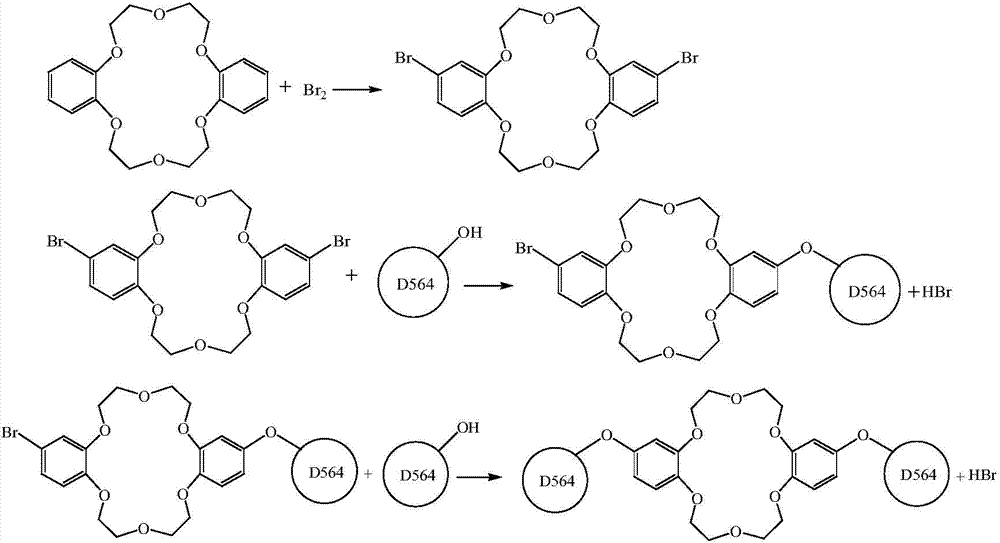

[0041] 1. Preparation of boron-strontium composite adsorbent

[0042] Raw materials: boron adsorption material is D564 boron selective resin, commercially available; strontium adsorption material is bisbenzo 18-crown-6, Fluka Reagent Company.

[0043] Bromination: Weigh 10g of bisbenzo-18-crown-6 and dissolve in 300mL CHCl 3 , forming a colorless and transparent solution; adding 10 g of liquid bromine to form a yellow system; heating the reaction system to reflux for 35 minutes, and the system turned orange-red, and after 2 hours, the reflux reaction was complete to obtain an orange-red clear solution.

[0044] Compounding: Mix 65mL of bromination reaction solution with 2g of D564 boron resin, slowly add 40mL of 10% NaOH solution dropwise, seal, and stir for 24 hours. The product was filtered out, washed successively with chloroform and distilled water until neutral, and dried at 60°C for 4 hours to obtain off-white spherical particles.

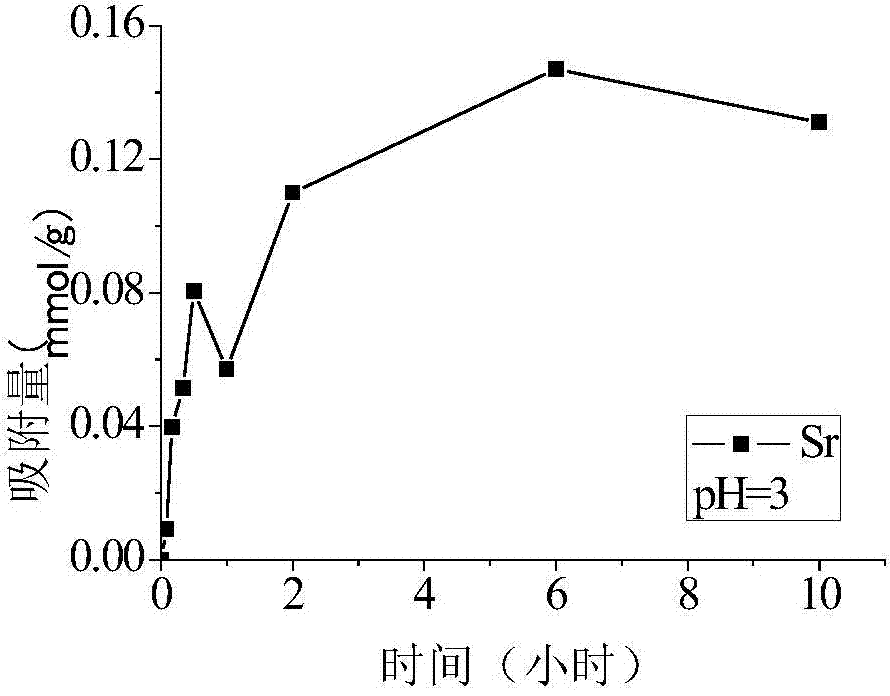

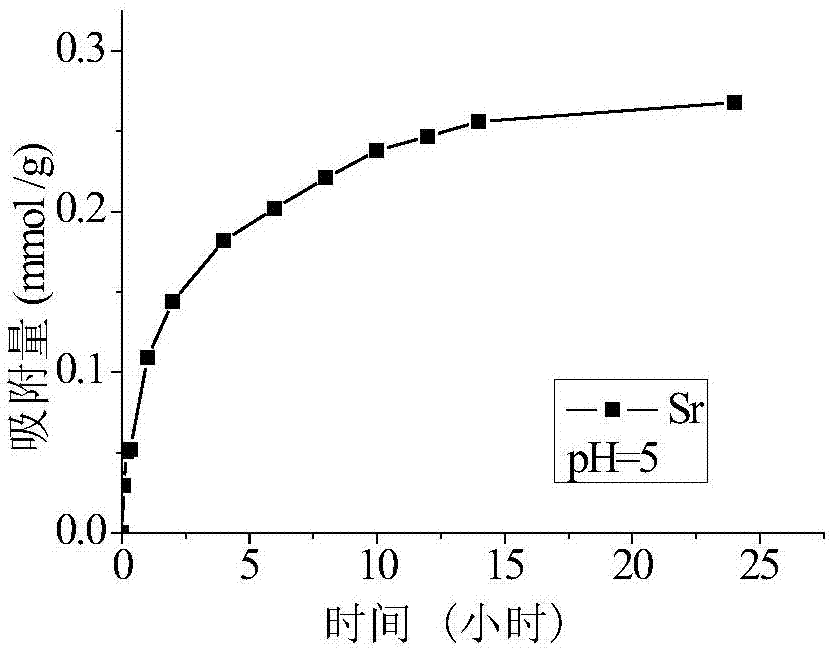

[0045] The D564 resin itself only ha...

Embodiment 2

[0055] 1. Preparation of boron-strontium composite adsorbent

[0056] The raw materials and preparation method are the same as in Example 1, except that different relative amounts of raw materials are used in Example 2. The amount of D564 resin and bromocrown ether-chloroform solution, and the quality of the obtained boron strontium ion composite adsorbent are shown in Table 1 below.

[0057] Table 1 bromocrown ether-chloroform solution, D564 resin, and the amount of the obtained boron strontium ion composite adsorbent

[0058]

[0059]

[0060] Similar to Example 1, the D564 resin itself only has adsorption to boron, but no adsorption to strontium. After being synthesized into the composite adsorbent of the present invention, the adsorption to strontium is better, and along with the addition of strontium adsorption material (crown ether) in the synthesis ) changes, the adsorption amount of strontium also changes, which shows that the crown ether is loaded on the D564 r...

Embodiment 3

[0068] 1. Preparation of boron-strontium composite adsorbent

[0069] Raw material: The strontium adsorption material is bis-benzo-18-crown-6, Fluka Reagent Company.

[0070] Preparation of boron adsorption material (organosilicon hybrid gel): mix 19.5g N-methylglucamine with 24mL γ-(2,3-glycidoxy)propyltrimethoxysilane (the ratio of substances is 1: 1) Mix 100mL N,N-dimethylformamide, stir and react at 75°C until a milky white waxy substance is produced (it takes about 4 hours), take out the milky white waxy substance, and cool it for later use.

[0071] Dissolve 20g of the cooled waxy substance in 5mL of water, add 5mL of bis(γ-trimethoxysilylpropyl)amine dropwise with stirring until a gel is formed, seal it and let it stand for 24 hours, take it out and dry it at 30°C, Grind and sieve, take 20-60 mesh, wash several times with water, and dry at 30°C to obtain organosilicon hybrid gel boron adsorbent.

[0072] Bromination: with embodiment 1. Composite: Same as Example 1, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com