Fiber-reinforced composite material and preparation method thereof

A technology of fiber reinforcement and composite materials, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of low strength, poor impact resistance, and easy damage of ACM materials, and achieve strong designability , avoid the effect of strong direct sunlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

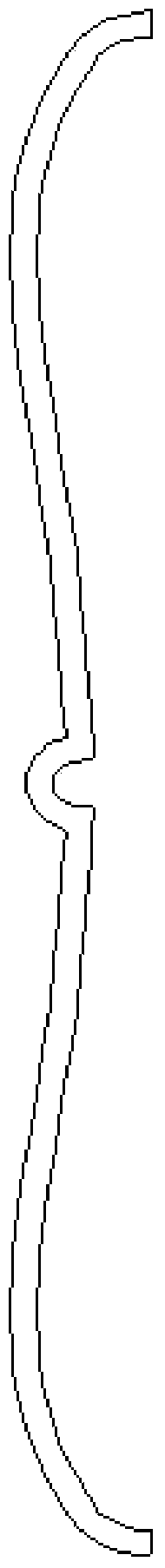

[0027] Specific implementation mode one: the cross section of the product in this implementation mode is as follows figure 1 As shown, the processing method is as follows:

[0028] Mix according to the ratio of 1.1kg of glass chopped fiber, 2.6kg of polyethylene terephthalate slurry, and 13g of cyclohexanone peroxide-cobalt naphthenate system, and form it by RTM process. The release agent is polyvinyl alcohol.

[0029] Then apply 0.5mm thick isophthalic neopentyl glycol gel coat resin (containing 0.2% UV-327 ultraviolet absorber), electrostatic spraying. The BASF HDI biuret polyurethane automotive paint with a thickness of 0.15 mm is attached to a polyvinyl monofluoride film to obtain a product. The quality indicators of this product are:

[0030] The thickness is 3.2mm, the glass fiber content is 30%, the tensile strength is 132MPa, the bending strength is 120MPa, and the impact strength is 86GPa.

[0031] Gel coat thickness 0.40mm, BASF thickness 0.17mm.

specific Embodiment approach 2

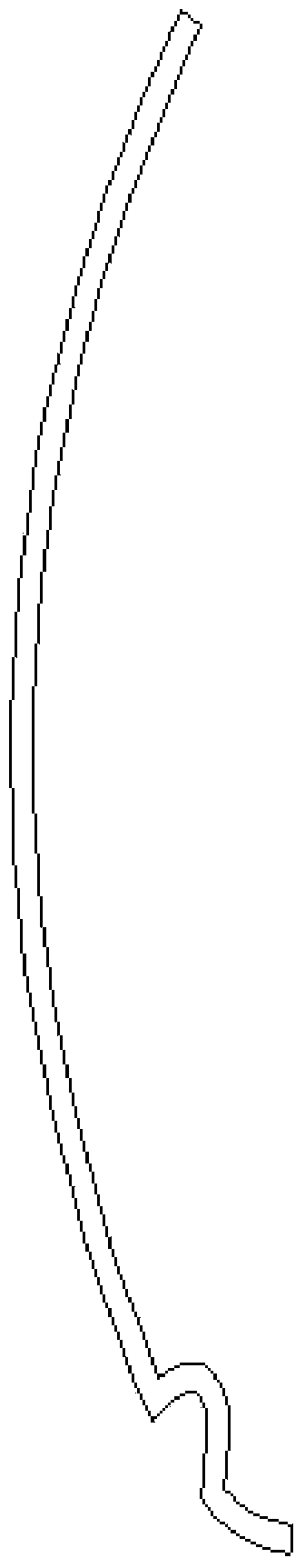

[0032] Specific implementation mode two: the cross section of the product in this implementation mode is as follows figure 2 As shown, the polyethylene terephthalate slurry is replaced with the polyethylene terephthalate slurry, and other steps and parameters are the same as those in the first embodiment.

[0033] The quality index of the composite material described in the present embodiment is:

[0034] The thickness is 3.25mm, the glass fiber content is 30%, the tensile strength is 121MPa, the bending strength is 120MPa, the impact strength is 80GPa, the gel coat thickness is 0.45mm, and the BASF paint thickness is 0.18mm.

specific Embodiment approach 3

[0035] Specific implementation mode three: the processing method of fiber-reinforced composite material in this implementation mode:

[0036] Glass fiber mat 0.75Kg, polyethylene adipate slurry 2.99kg, benzoyl peroxide-tertiary amine system 8.9g formula, molded by RTM process, release agent is polyvinyl chloride film. The product is coated with 0.5mm thick pearlescent gel coat resin (containing 0.25% UV-9 ultraviolet absorber), electrostatically sprayed with 0.15mm thick HDI polyisocyanate BASF automotive paint, and then pasted with polyvinyl monofluoride film to obtain the product.

[0037] The quality index of the composite material described in the present embodiment is:

[0038] Thickness 3.2mm, glass fiber content 20%, tensile strength 110MPa, bending strength 80MPa, impact strength 75GPa, gel coat thickness 0.44mm, BASF paint thickness 0.178mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com