Manganese dioxide nanowire array electrode on titanium substrate and preparation method thereof

A manganese dioxide nano-wire array technology, applied in electrode manufacturing, nanostructure manufacturing, manganese oxide/manganese hydroxide and other directions, can solve the problems of uneven growth of manganese dioxide nanowires and cannot be applied on a large scale. The effect of industrial application, good supercapacitive performance, good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

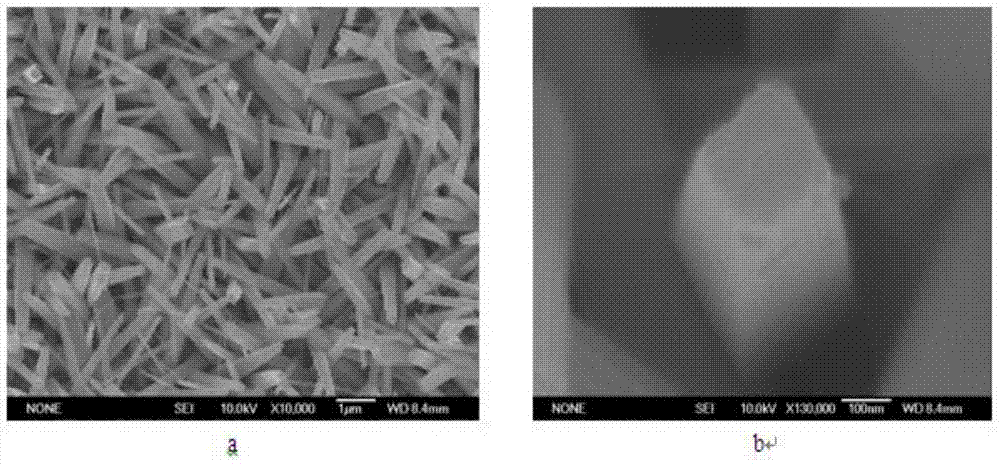

[0018] A manganese dioxide nanowire array electrode on a titanium substrate, the preparation method of which comprises: adding 0.6 grams of potassium permanganate (KMnO 4 ) dissolved in 35 ml of acetone (C 3 h 6 O), 5 ml of deionized water and 0.1 ml of 37% (mass fraction) hydrochloric acid solution (HCl), stir with a magnetic stirrer to fully dissolve, mix evenly, and make a mixed solution; place the titanium metal sheet into the prepared mixed solution; then sealed and heated to 200 degrees in the reaction kettle, and kept for 9 hours; after natural cooling, the titanium metal sheet was taken out to obtain the manganese dioxide nanowire array sample on the titanium substrate. The sample was observed with a scanning electron microscope, the results are shown in figure 1 , figure 1 The results show that its single manganese dioxide nanowires have a diameter of 300-500 nanometers and are vertically, uniformly and densely distributed on the surface of titanium metal in an arr...

Embodiment 2

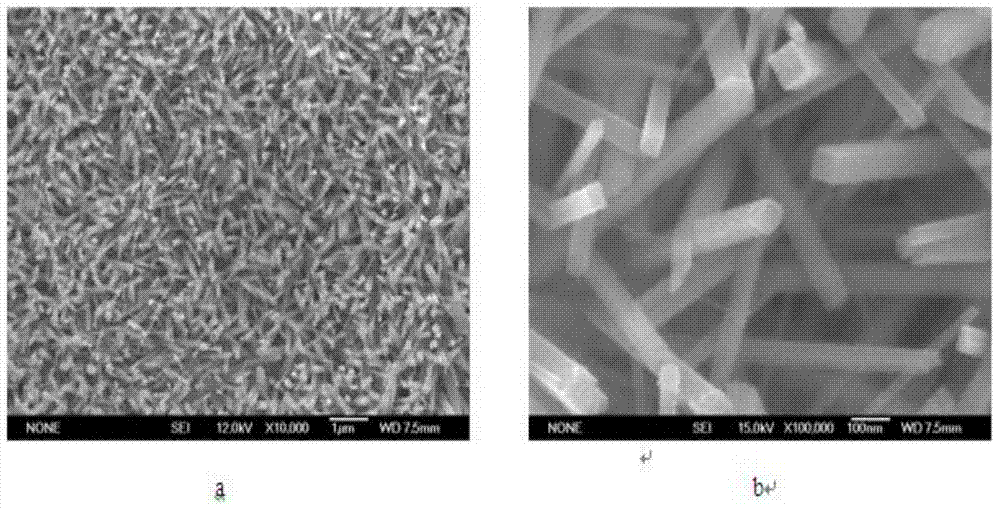

[0021] A manganese dioxide nanowire array electrode on a titanium substrate, the preparation method of which comprises: adding 0.45 grams of potassium permanganate (KMnO 4 ), dissolved in 35 ml of acetone (C 3 h 6 O), 5 milliliters of deionized water and 0.16 milliliters, 37% (mass fraction) of hydrochloric acid solution (HCl), stir with a magnetic stirrer to make it fully dissolve, mix evenly, and make a mixed solution; place the titanium metal sheet into the prepared solution; then sealed and heated to 200 degrees in the reaction kettle, and kept for 10 hours; after natural cooling, the titanium metal sheet was taken out to obtain the manganese dioxide nanowire array sample on the titanium substrate. The sample was observed with a scanning electron microscope, the results are shown in figure 2 . figure 2 The results show that its single manganese dioxide nanowires have a diameter of 80-100 nanometers and are vertically, uniformly and densely distributed on the surface o...

Embodiment 3

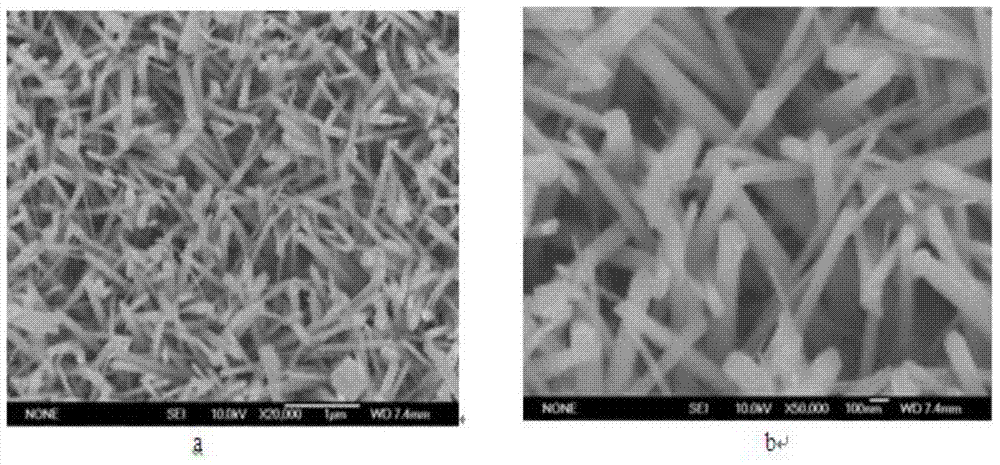

[0025] A manganese dioxide nanowire array electrode on a titanium substrate, the preparation method comprising: adding 0.26 grams of potassium permanganate (KMnO 4 ), dissolved in 18 ml of acetone (C 3 h 6 O), 3 milliliters of deionized water and 0.065 milliliters, 37% (mass fraction) of hydrochloric acid solution (HCl), stir with a magnetic stirrer to make it fully dissolve, mix evenly, and make a mixed solution; put the titanium sheet into In the solution that has been prepared; Seal and heat to 200 degree then in the autoclave of polytetrafluoroethylene liner (100 milliliters), keep 9 hours; After natural cooling, titanium metal sheet is taken out, obtains the manganese dioxide nanowire on the titanium substrate Array samples. The samples were observed with a scanning electron microscope, the results are shown in image 3 . image 3The results show that its single manganese dioxide nanowires have a diameter of 50-100 nanometers and are vertically, uniformly and densely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com