Preparation method of ultrathin nanosheet semiconductor material

A nanosheet, semiconductor technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low yield of semiconductor materials, high investment, complex equipment and conditions, etc., to achieve effective absorption and utilization, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

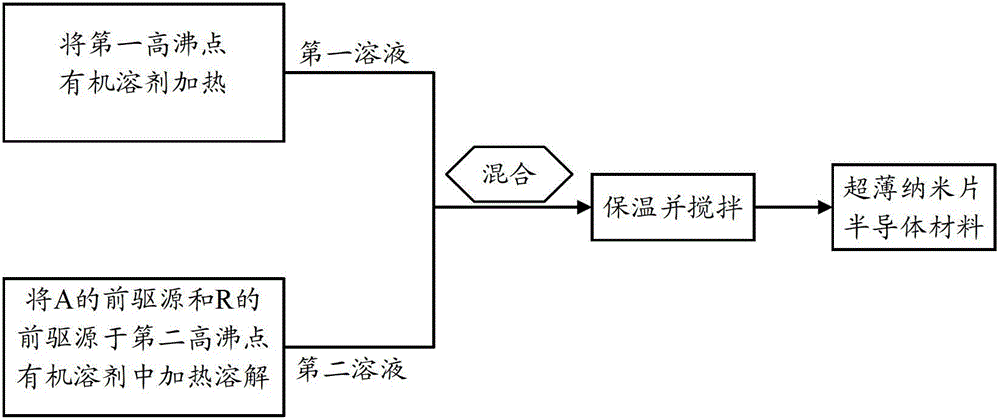

[0033] Such as figure 1 As shown, the invention discloses a method for preparing an ultra-thin nanosheet semiconductor material, comprising the following steps:

[0034] Step 1: heating the first high boiling point organic solvent to obtain the first solution. This step can provide a reaction solvent with a certain temperature, and the purpose of heating is to fully remove the moisture and oxygen in the first high-boiling point organic solvent. Preferably, the heating temperature is 200-320°C, and the first high-boiling-point organic solvent can be selected from one or more of oleylamine, oleic acid, dibenzylamine, dibenzyl ether, octadecene and diisooctylamine , wherein the volume of the first high-boiling organic solvent does not need to be strictly controlled, but for the convenience of operation, it can be proportional to the volume of the second high-boiling organic solvent in the second step.

[0035] In order to heat more uniformly and fully isolate oxygen and water v...

Embodiment 1

[0045] In a 50mL three-neck flask, add 15.0ml oleylamine and 15.0ml oleic acid, heat to 180°C at a heating rate of 20°C / min, keep it warm for 1 hour, and then heat to 320°C at a heating rate of 20°C / min to obtain the first solution; add 0.1mmol phenyl bismuth and 0.2mmol phenyl selenium to 10ml of oleylamine solution and heat at 60°C until completely dissolved to obtain the second solution; mix the first solution and the second solution and heat at 300°C Under stirring for 20min, the final product was washed and sonicated to obtain the ultrathin nanosheet Bi 2 Se 3 .

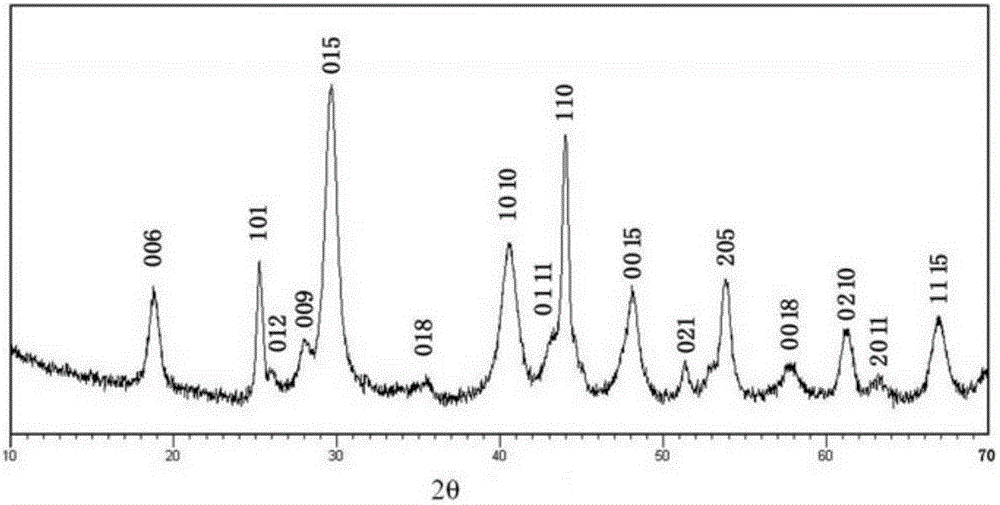

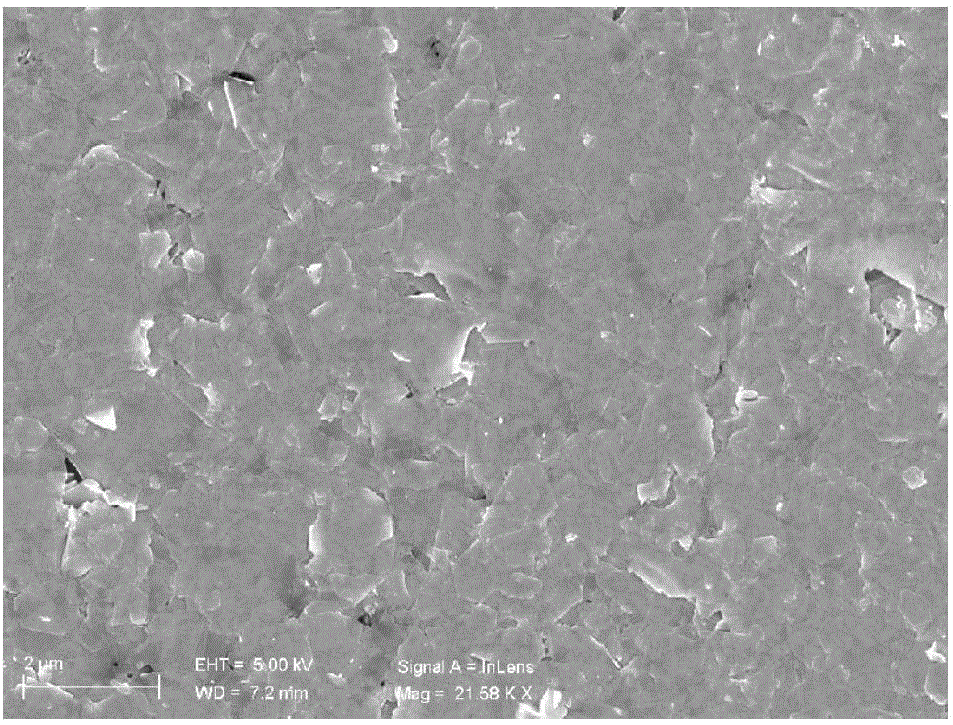

[0046] Such as Figure 2 to Figure 6 As shown, the product is a single crystal ultrathin nanosheet Bi with a thickness of about 1 nm 2 Se 3 Material. Photothermal performance tests show that the prepared ultrathin nanosheets Bi 2 Se 3 The photothermal conversion power is greater than 8W / g, which is not lower than the conversion efficiency of activated carbon under the same conditions. In ultra-thin nanoma...

Embodiment 2

[0048] In a 50mL three-neck flask, add 5.0ml of dibenzylamine, heat it to 150°C at a heating rate of 10°C / min, keep it warm for 30min, and then heat it to 300°C at a heating rate of 15°C / min to obtain the first solution; Add mmol phenyl bismuth and 0.2 mmol phenyl selenium to 0.1 ml of dibenzylamine solution and heat at 100°C until completely dissolved to obtain the second solution; mix the first solution and the second solution and stir at 250°C 100min, wash and sonicate the final product to obtain the ultrathin nanosheet Bi 2 Se 3 .

[0049] The properties of the resulting product were tested, and the product was a single-crystal ultrathin nanosheet Bi with a thickness of about 1 nm. 2 Se 3 Material. Photothermal performance tests show that the prepared ultrathin nanosheets Bi 2 Se 3 The photothermal conversion power is greater than 8W / g, which is not lower than the conversion efficiency of activated carbon under the same conditions. In ultra-thin nanomaterials, its si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com