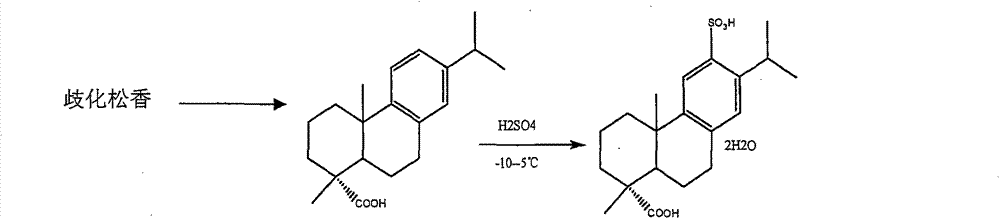

Method for preparing sulfonated dehydroabietic acid

A technology of dehydroabietic acid and disproportionated rosin, which is applied in the field of preparation of sulfonated dehydroabietic acid, can solve the problems of unfavorable scale-up production, cumbersome operation, and high energy consumption, so as to reduce the generation of by-products and increase the reaction yield , The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

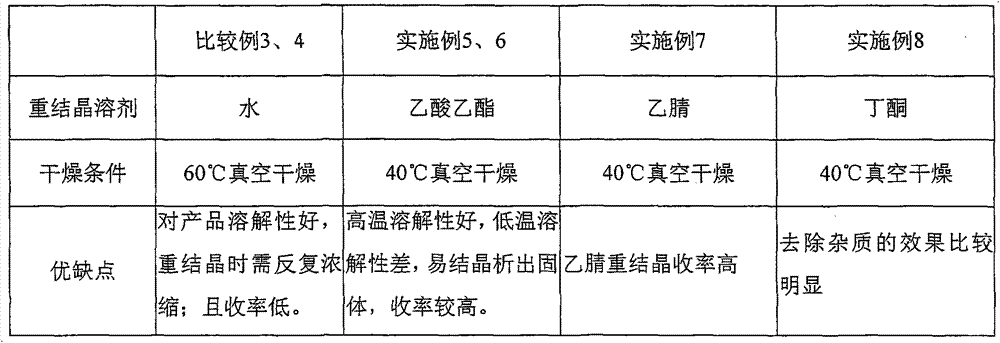

Examples

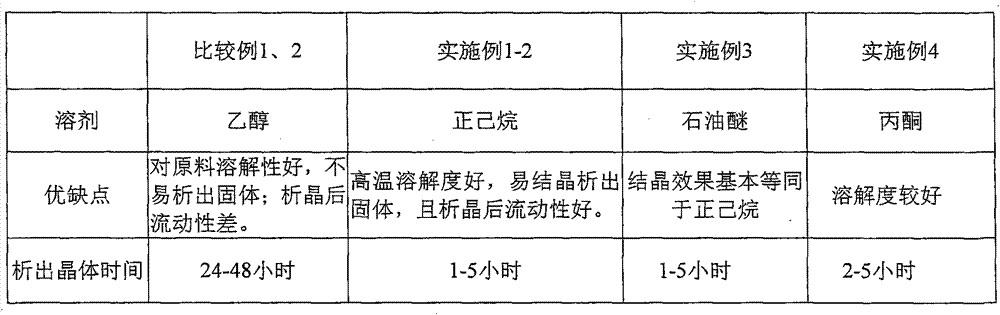

Embodiment 1

[0022] Embodiment 1:-extract dehydroabietic acid

[0023] Add 12Kg of disproportionated rosin into 32L of n-hexane, heat to reflux (about 2.5 hours) to completely dissolve, then cool to about 0°C under stirring, keep the temperature for 5h, a large amount of solids are precipitated, centrifuge, and air-dry the filter cake at 40°C for 15 hours to obtain 5.92Kg white solid. Its purity was 91.8% as detected by HPLC.

Embodiment 2

[0024] Embodiment 2:-extract dehydroabietic acid

[0025] Add 1kg of disproportionated rosin into 3L of n-hexane, heat to reflux for 1 hour and dissolve completely, then cool to about 0°C under stirring, keep the temperature for 5h, a large amount of solids are precipitated, filter, and air-dry the filter cake at 40°C for 15 hours to obtain 460g of white solid. Its purity was 91.25% as detected by HPLC.

Embodiment 3

[0026] Embodiment 3:-extract dehydroabietic acid

[0027] Take 1 kg of disproportionated rosin and add it to 3L60-90# petroleum ether, heat it to reflux for 30 minutes and dissolve it completely, then cool it to about 0°C under stirring, keep the temperature for 4 hours, a large amount of solids are precipitated, filter, and air-dry the filter cake at 40°C for 20 hours to obtain 450 g of white solid. Its purity was 91.86% as detected by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com