A solvent-based block polymer dispersant

A polymer dispersant and block polymer technology, which is applied in the field of new structure pigment polymer dispersant and its preparation, can solve the problem that it is difficult to precisely control the monomer distribution, cannot prepare block copolymers, and can be freed by free radical polymerization. To solve problems such as low degree of control, to achieve the effect of shortening grinding time, high product purity, and preventing pigment flocculation and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

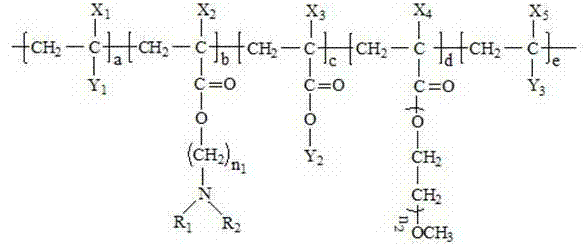

[0017] A solvent-based block polymer dispersant, the molecular chain of the dispersant includes an anchor segment and a solvation segment, and the structural formula is as follows:

[0018]

[0019] Among them, X1, X2, X3, X4, X5 are H; Y1 is a nitrogen-containing aromatic ring; Y2 is a C1-C10 alkyl group or a hydroxyl-containing alkyl group or a mixture; Y3 is a phenyl group or a nitrile group; R1, R2 It is a C1-C10 alkyl group, the anchor segment is part a and b in the molecular formula, and the solvating segment is part c, d and e in the molecular formula. n1=1, n2=1, a=1, b=1, c=5, d=1, e=5, the anchor segment is composed of homopolymer or copolymer of nitrogen-containing vinyl monomer, its molecular weight It is 105 g / mol, and the mass percentage in the polymer is 2%. The solvating segment is composed of a homopolymer or copolymer of nitrogen-free vinyl monomer, its molecular weight is 105 g / mol, and its mass percentage in the polymer is 50%. At 60-90 degrees Celsius...

Embodiment 2

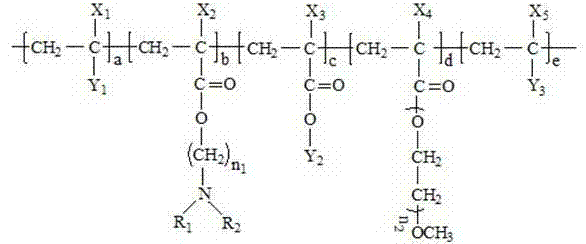

[0021] A solvent-based block polymer dispersant, characterized in that: the molecular chain of the dispersant includes an anchor segment and a solvation segment, and the structural formula is as follows:

[0022]

[0023]Among them, X1, X2, X3, X4, X5 are CH3; Y1 is nitrogen-containing aromatic ring; Y2 is C1-C10 alkyl or hydroxyl-containing alkyl or mixture; Y3 is phenyl, nitrile; R1, R2 It is a C1-C10 alkyl group, the anchor segment is part a and b in the molecular formula, and the solvating segment is part c, d and e in the molecular formula. n1=2, n2=4, a=1~100, b=30, c=10, d=5, e=8. The anchor segment is composed of homopolymer or copolymer of nitrogen-containing vinyl monomer, its molecular weight is 105-10000 g / mol, and its mass percentage in the polymer is 50%. The solvated segment is composed of a nitrogen-free vinyl monomer homopolymer or copolymer, with a molecular weight of 20,000 g / mol and a mass percentage of 98% in the polymer. At 90 degrees Celsius, add an...

Embodiment 3

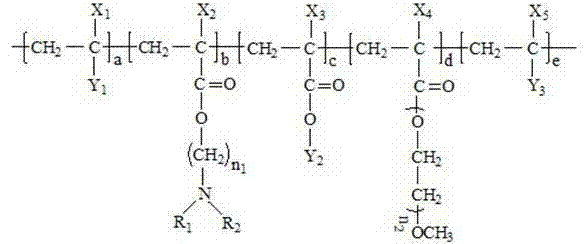

[0025] A solvent-based block polymer dispersant, the molecular chain includes an anchor segment and a solvation segment, and the structural formula is as follows:

[0026]

[0027] Among them, X1, X2, X3, X4, X5 are CH3; Y1 is nitrogen-containing aromatic ring; Y2 is C1-C10 alkyl or hydroxyl-containing alkyl or mixture; Y3 is phenyl, nitrile; R1, R2 It is a C1-C10 alkyl group, the anchor segment is part a and b in the molecular formula, and the solvating segment is part c, d and e in the molecular formula. n1=3, n2=5, a=50, b=50, c=30, d=30, e=10. The anchor segment is composed of a homopolymer or copolymer of nitrogen-containing vinyl monomers, its molecular weight is 10,000 g / mol, and its mass percentage in the polymer is 50%. The solvated segment of the polymer is composed of a homopolymer or copolymer of nitrogen-free vinyl monomers, its molecular weight is 20,000 g / mol, and its mass percentage in the polymer is 98%. At 60-90 degrees Celsius, add anchoring segment mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com