Air compressor oil and preparation method thereof

A technology of air compressor oil and paraffin base oil, applied in the chemical field, can solve the problems of poor viscosity and viscosity-temperature performance, high carbon deposition tendency, short service life, etc., and achieve the effect of excellent high temperature oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

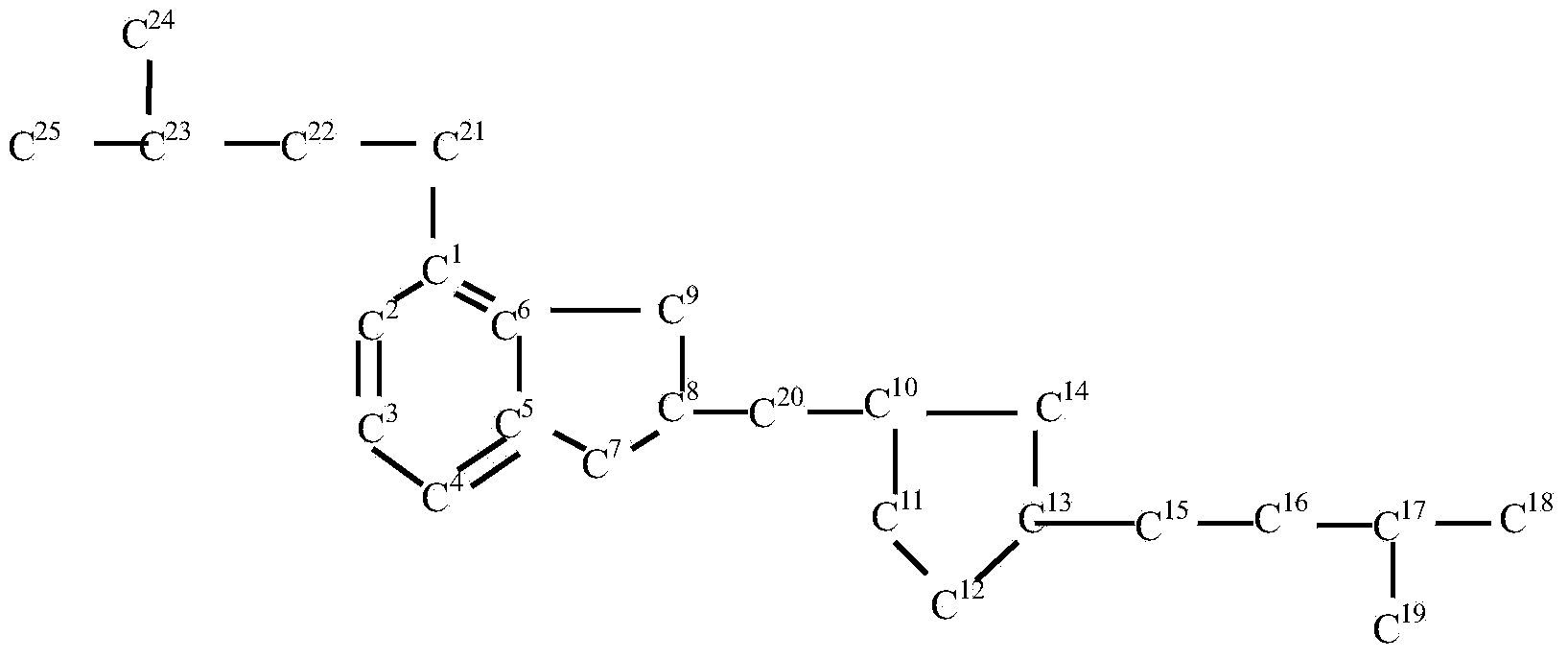

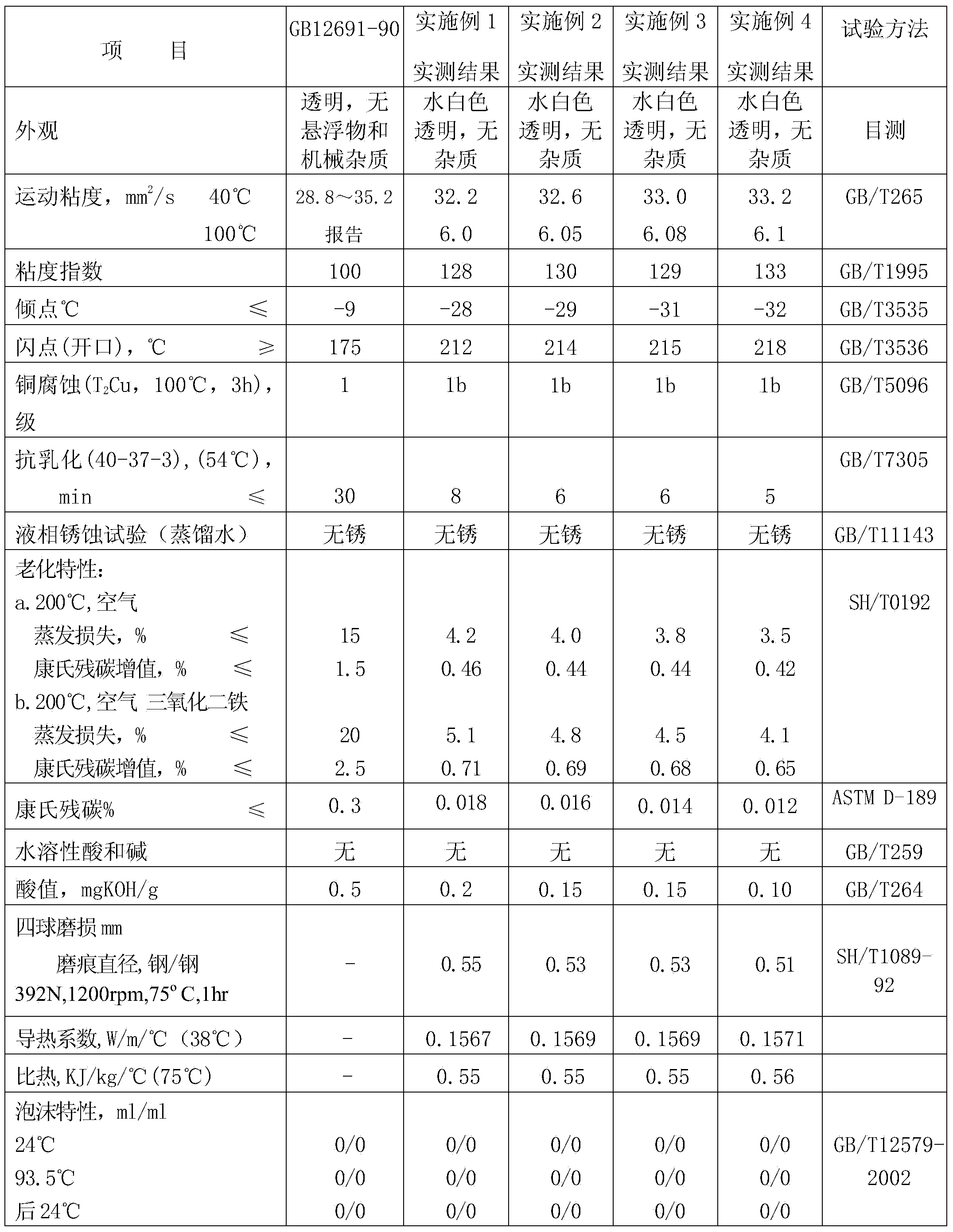

[0040] The present invention provides an air compressor oil, which is a hydrogenated paraffinic base oil fraction, a hydrogenated naphthenic oil fraction, a hydrogenated alkyl high boiler, a phenolic antioxidant, an anilinyl antioxidant, etc. Oxygen agent, alkenoic acid antioxidant, metal deactivator, ashless anti-wear agent, defoamer, anti-light sensitive agent, the hydrogenated paraffin base oil fraction of the catalytic cracking of the petroleum is compressed in the air The mass percentage in the engine oil is 80%, the mass percentage of the hydrogenated naphthenic oil fraction in the air compressor oil is 16.098%, and the hydrogenated alkyl high boiler fraction is in the The mass percentage of the air compressor oil is 3%, and at 110°C, add clay with a mass percentage of 2% of the air compressor oil for refining, and at the same time, carry out stirring and refining adsorption for 40 minutes until the adsorption reaction is uniform, and the precipitation is filtered. After...

Embodiment 2

[0054] The present invention provides an air compressor oil, which is a hydrogenated paraffinic base oil fraction, a hydrogenated naphthenic oil fraction, a hydrogenated alkyl high boiler, a phenolic antioxidant, an anilinyl antioxidant, etc. Oxygen agent, acid antioxidant, metal deactivator, ashless anti-wear agent, defoamer, anti-light sensitive agent. The mass percentage of the hydrogenated paraffinic base oil fraction in the air compressor oil of the catalytic cracking of the petroleum is 75%, and the hydrogenated naphthenic oil fraction in the air compressor oil is 75%. The mass percentage is 18.225%, the mass percentage of the hydrogenated alkyl high boiler fraction in the air compressor oil is 5%, and the clay with a mass percentage of 2% of the air compressor oil is added at a temperature of 115°C Refining, at the same time carry out stirring and refining adsorption for 40 minutes, until the adsorption reaction is uniform, and after the precipitation is filtered throug...

Embodiment 3

[0068] The present invention provides an air compressor oil, which is a hydrogenated paraffinic base oil fraction, a hydrogenated naphthenic oil fraction, a hydrogenated alkyl high boiler, a phenolic antioxidant, an anilinyl antioxidant, etc. Oxygen agent, acid antioxidant, metal deactivator, ashless anti-wear agent, defoamer, anti-light sensitive agent. The mass percentage of the hydrogenated paraffinic base oil fraction in the air compressor oil of the catalytic cracking of the petroleum is 70%, and the hydrogenated naphthenic oil fraction in the air compressor oil is 70%. The mass percentage is 22.292%, the mass percentage of the hydrogenated alkyl high boiler fraction in the air compressor oil is 5%, and the air compressor oil mass percentage of 4% clay is added at a temperature of 120°C Refining, stirring and refining adsorption for 50 minutes at the same time, until the adsorption reaction is uniform, after the precipitation is filtered through a filter for 3 times, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com