Method for biologically synthesizing poly-3-hydroxypropionic acid

A technology for synthesizing enzymes and malonyl coenzymes, which is applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of inability to apply industrialized production, complex fermentation processes, and high production costs, and achieve low cost. , the effect of wide source of raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

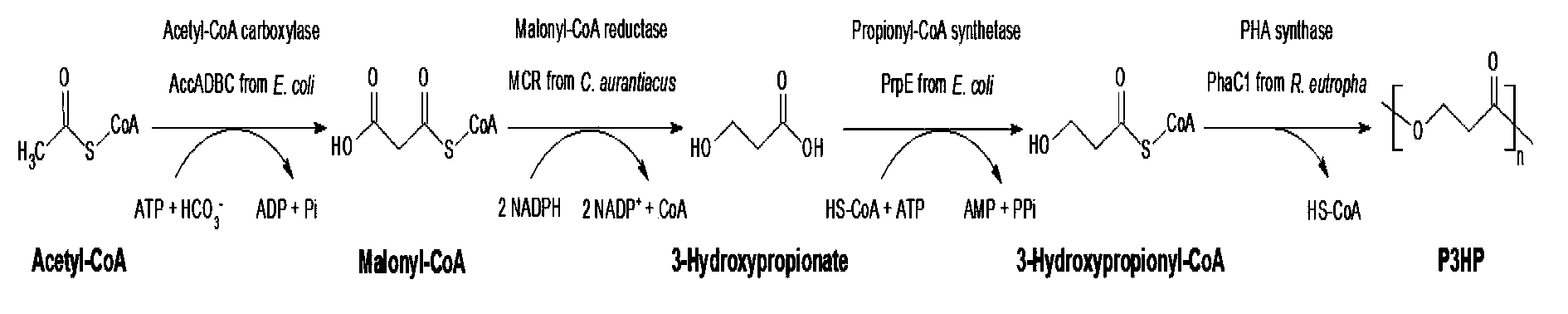

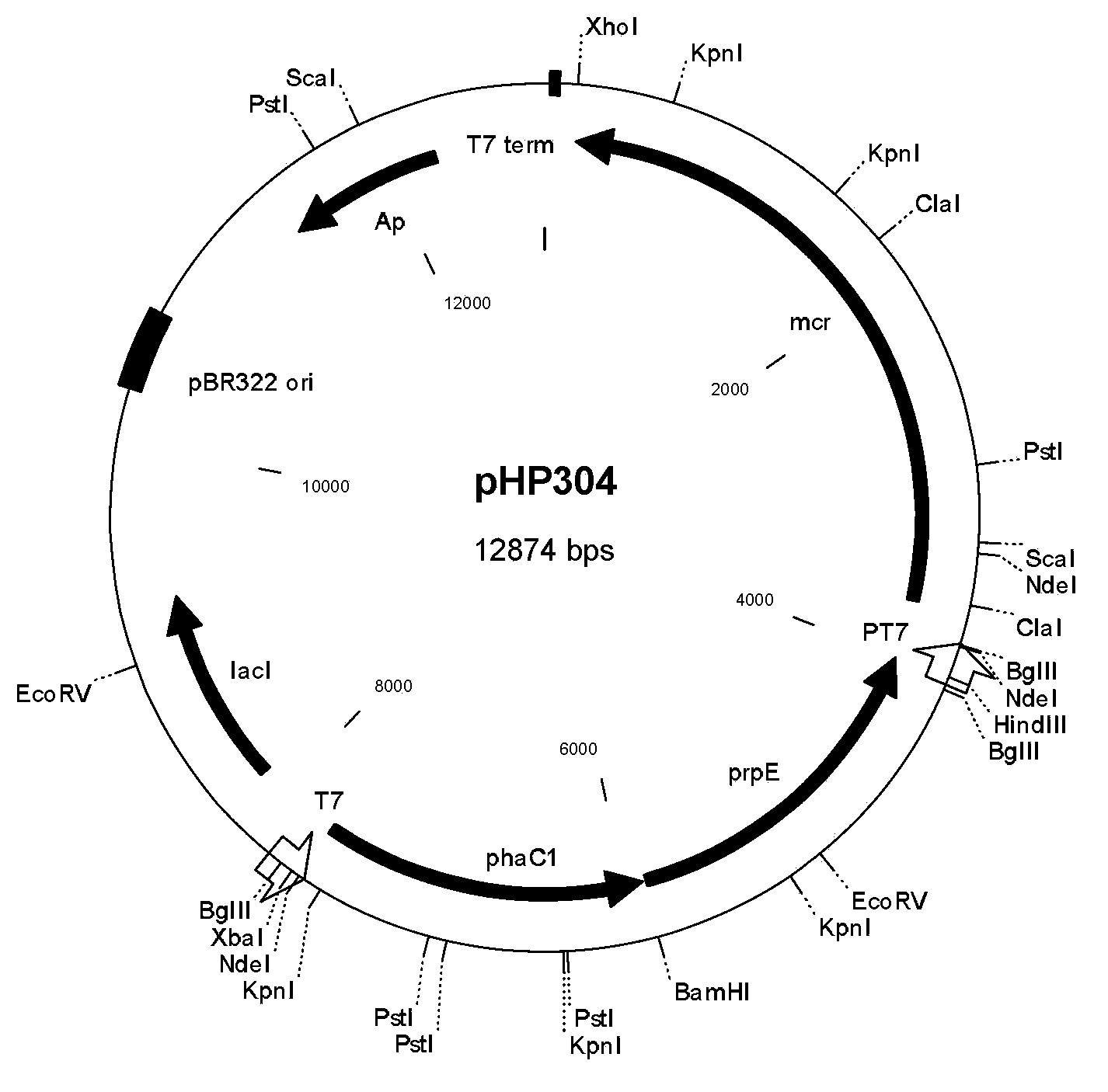

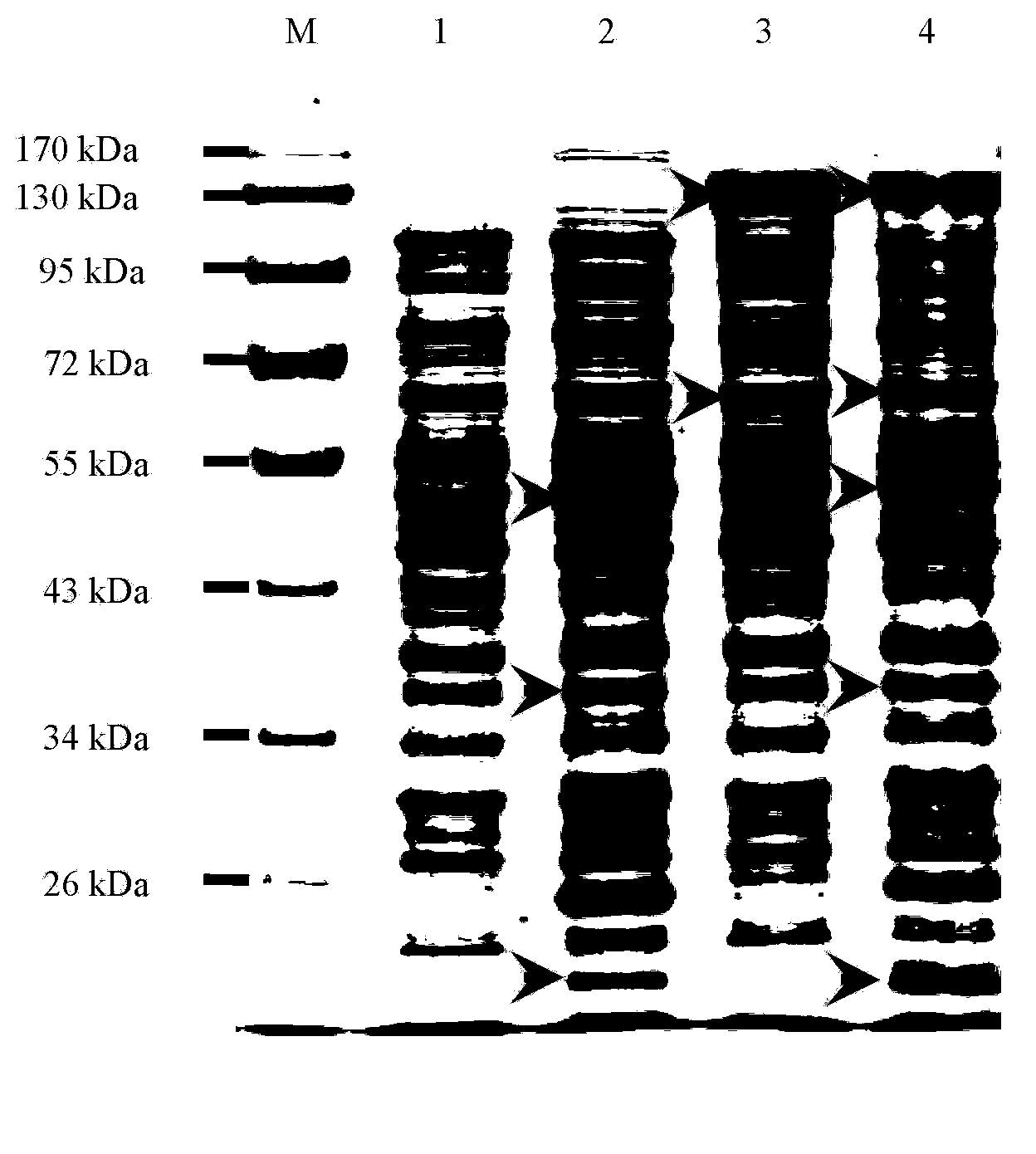

[0097] By co-overexpressing the acetyl-CoA carboxylase gene (acc) and propionyl-CoA synthetase gene (prpE) from Escherichia coli (E.coli), derived from C.aurantiacus (orange green flexure The malonyl-CoA reductase gene (mcr) from R.eutropha (Alcaligenes eutropha) and the polyhydroxy fatty acid synthase gene (phaC) from R. Poly-3-hydroxypropionic acid.

[0098] Those skilled in the art should understand that the co-cloning of the above four genes into Escherichia coli cells is carried out in accordance with standard molecular cloning techniques. Moreover, according to actual needs, appropriate E. coli codon optimization can be performed on genes not derived from E. coli, so as to be better expressed in E. coli. In the present invention, the inventors found that the malonyl-CoA reductase gene (mcr) derived from C. aurantiacus (Chloroflexus aurantiacus) can be expressed in E. For good expression, the polyhydroxy fatty acid synthase gene (phaC) from R. eutropha (Alcaligenes eutr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com