Air supply system of solid particle fuel stove

A solid particle and air supply system technology, applied in the field of stoves, can solve problems such as environmental pollution, waste of fuel resources, and air without preheating, and achieve the effects of reducing environmental pollution, saving resources, and fully burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

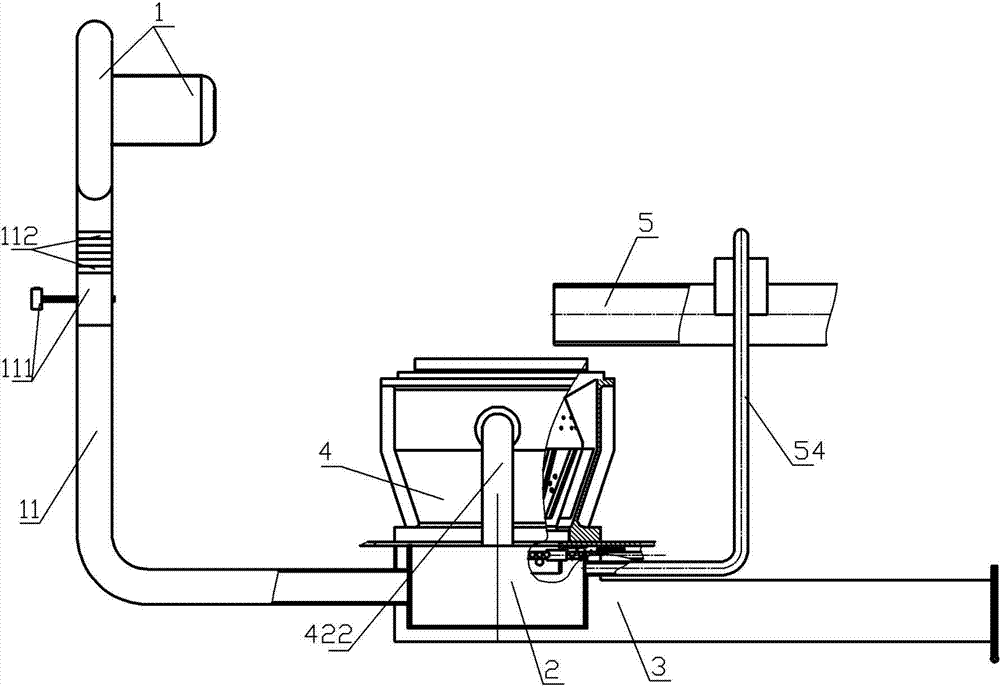

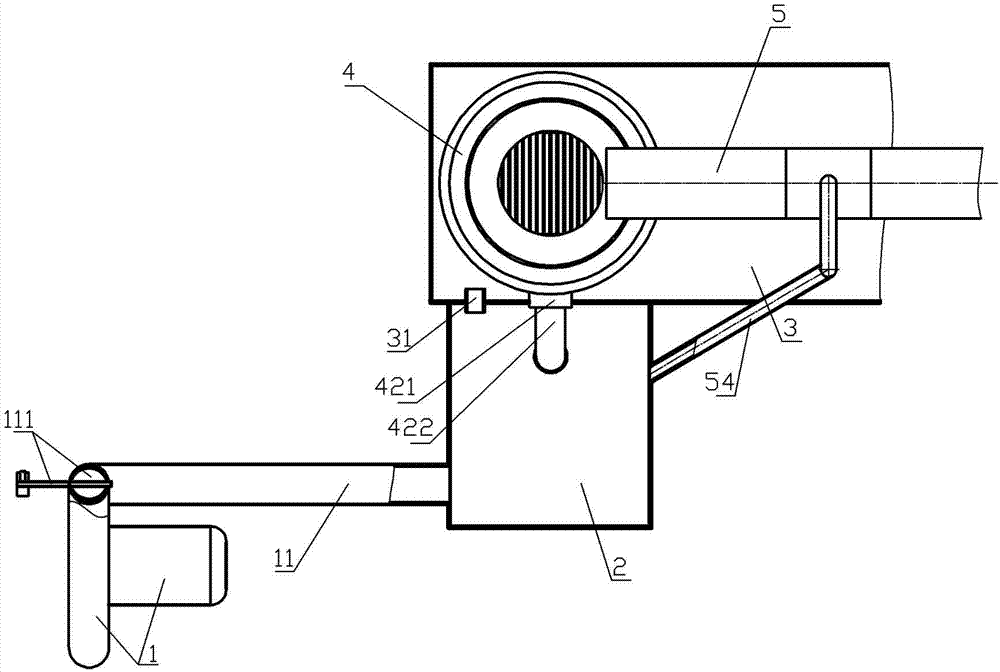

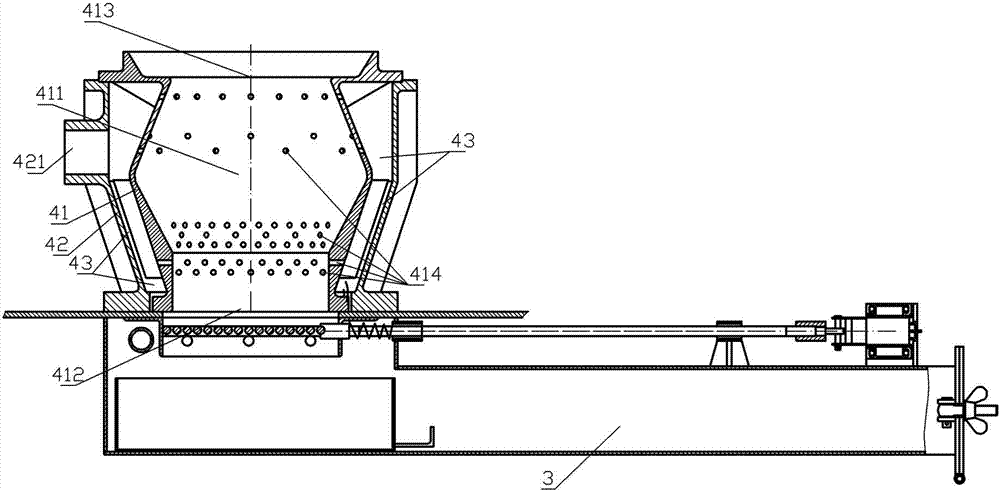

Embodiment 1

[0028] Such as Figure 1-4 Shown: an air supply system for a solid particle fuel stove, which includes a blower 1, an air distribution chamber 2, a bottom box 3, a gasification burner 4 and a feeding device 5; the gasification burner 4 is installed in the hearth of the stove, The gasification burner 4 is tubular (i.e., a cylindrical shape with upper and lower openings), inside which is a gasification combustion chamber 411, and its tube wall is divided into inner and outer layers, that is, the gasification burner 4 includes a gasification combustion core 41 and a core jacket 42 The interior of the gasification combustion core 41 is a cavity with upper and lower openings, the cavity in the gasification combustion core 41 is a gasification combustion chamber 411, and the opening at the bottom of the gasification combustion core 41 is an ash outlet 412, which is also a combustion-supporting fuel The air inlet, the upper opening of the gasification combustion core 41 is the flame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com