Manufacturing device for electronic circuit based on graphene and manufacturing method thereof

A technology for electronic circuits and manufacturing methods, which is applied in the formation of conductive patterns, textiles and papermaking, fiber processing, etc., can solve problems such as size limitations, and achieve the effects of good thermal and mechanical properties and high electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

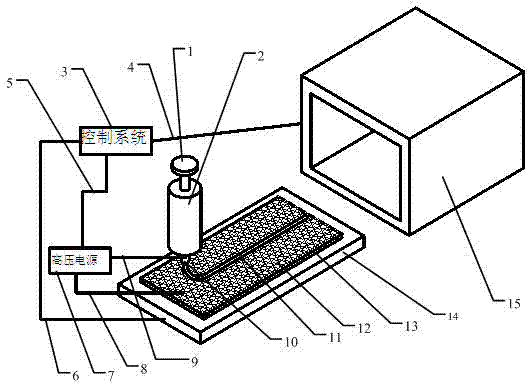

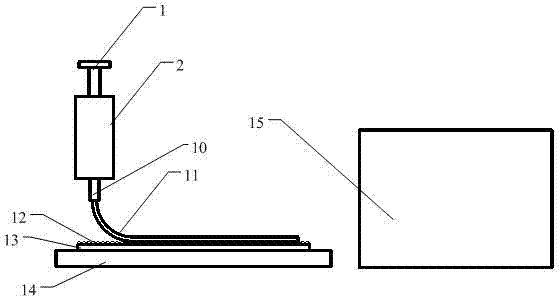

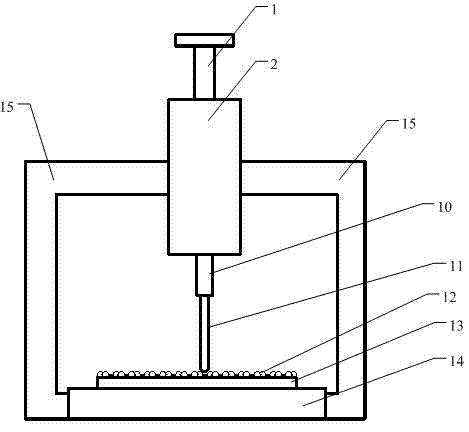

[0031] The structure diagram of the present invention is as figure 1 , 2 , 3, and 4, the manufacturing equipment of graphene-based electronic circuits of the present invention includes a precision injector for feeding the electrospinning solution and realizing continuous spinning, and is deposited on a substrate by a graphene layer. The micro-nanofiber collection plate, the graphene layer is used as the conductive layer of the collection plate; it is used to provide the electrospinning electric field and form the high-voltage direct current power supply of the spinning environment, and is used to form the electrospinning nozzle 10 of the Taylor cone of electrospinning, for The controllable patterned deposition of micro-nano fibers provides an X-Y platform 14 of speed and direction, which is used for circuit design, numerical control machining and the control system 3 of the entire production process control, and is used to oxidize the graphene part that is not protected by mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com