Anti-ion type composite moisture absorption core

An ionic, absorbent core technology, which is applied in the fields of absorbent pads, medical science, textiles and papermaking, etc., can solve the problems of complex preparation process and high technical content of formula, achieve simple preparation process, increase production and use costs, and improve absorption effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

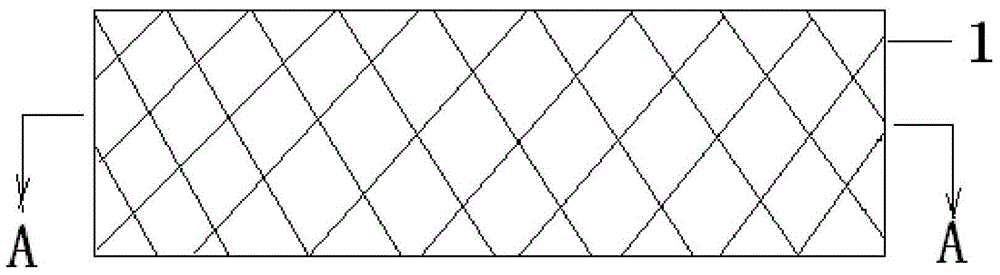

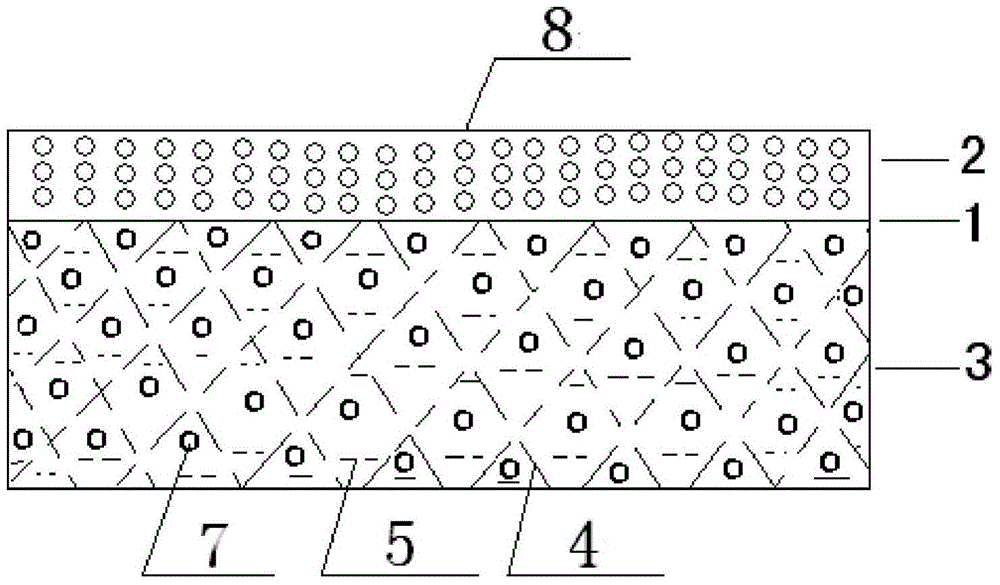

[0043] In order to further understand the present invention, now in conjunction with the attached figure 1 , 3 Describe it in detail.

[0044] (1) After carding the wood pulp fluff short fibers and thermoplastic short fibers into a web, spray a superabsorbent resin on the fiber web to form the absorbent core layer 3 of the composite hygroscopic core 1;

[0045] (2) Place the high-performance ion exchange membrane 8 on the absorbent core layer 3, and carry out hot air penetration in an oven at 140-160°C to melt the thermoplastic short fibers, so that the thermoplastic short fibers and the thermoplastic short fibers Bonding points are formed between the superabsorbent resin and between the thermoplastic short fiber and the ion exchange membrane material, and are subjected to pressure bonding to form a composite moisture-absorbing core 1 .

[0046] (3) According to product needs, the composite moisture-absorbing core can be cut into a rectangular shape.

Embodiment 2

[0048] as attached figure 1 , 4 Shown, a kind of composite hygroscopic core body of the present invention, its preparation method is as follows:

[0049] (1) After combing the wood pulp fluff short fibers and thermoplastic short fibers into a net, spraying ion exchange resin on the fiber net to form the ion exchange layer of the composite moisture-absorbing core;

[0050] (2) After combing the wood pulp fluff short fibers and thermoplastic short fibers into a web, spraying a superabsorbent resin on the fiber web to form the absorbent core layer of the composite hygroscopic core;

[0051] (3) The ion exchange layer material formed in step (1) or the absorbent core layer material formed in step (2) can be shaped by spraying latex or hot-melt pressure-sensitive adhesive.

[0052] (4) Latex or hot-melt pressure-sensitive adhesive is sprayed between the joint surfaces of the upper and lower structural materials for shaping and compounding to obtain a composite moisture-absorbing ...

Embodiment 3

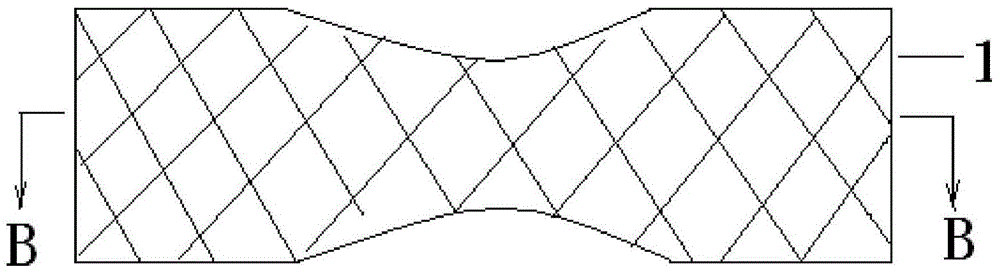

[0055] as attached figure 2 , 5 As shown, the ion exchange layer material and the absorbent core layer material of the composite moisture-absorbing core are obtained according to the process of steps (1) and (2) of Example 2, and then the heat-setting treatment is adopted.

[0056] After the above-mentioned absorbent core layer material, ion exchange layer material and absorbent core layer material are superimposed in sequence, hot air is penetrated in an oven at 140-160°C to melt the thermoplastic short fibers, so that between the thermoplastic short fibers, Bonding points are formed between the thermoplastic short fibers and the superabsorbent resin, and between the thermoplastic short fibers and the wood pulp fluff short fibers, and are bonded and molded by thermocompression to obtain a composite moisture-absorbing core body with a three-layer structure.

[0057] Similarly, the composite moisture-absorbing core can be cut into a dumbbell-shaped shape according to product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com